China PPR Pipes and Fittings for Hot and Cold Water Conveyance with Safety Guaranty

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 m

- Supply Capability:

- 250000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Features

1. Corrosion resistance

PPR pipes and fittings can resistant to most chemical corrosion; it can withstand PH value range 1-14 high concentration of acid and alkali corrosion over a wide temperature range.

2. Installation performance

PPR pipe PPR pipe is light in weight, and the operation installation is easy, which make it available to weld again. It is very important that pipe and pipe fittings can be welded together in seconds with a simple tool. Compared to traditional connection methods it can save 40%~50% of the time.

3. Safety Indicators

The basic component of PPR is carbon and hydrogen which is simple. It keeps in line with food hygiene regulations, non-toxic. If you use PPR pipe, there will no dirt in the inner wall or “secondary water pollution” caused by rust any more.PPR pipe ,green building materials, is more suitable for transporting drinking water.

Advantages of PPR pipe

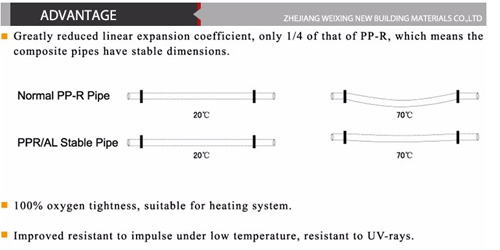

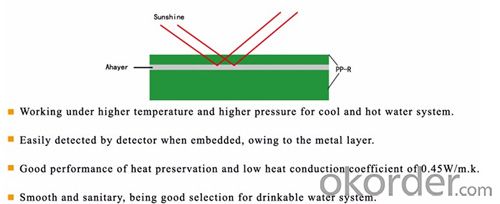

1. Maximum operating temperature can up to 95℃; it can work in a long term under the condition of 70℃ and 1.0Mpa.

2. PPR pipe density is only 1/8 of metal pipe; pressure resistance strength test is up 5Mpa, with good toughness, impact resistance.

3. Inner diameter of PPR pipe is little bigger than that of pipe fittings, which can ensure not to increase the resistance to fluid flow.

4. Inner wall of PPR pipe is smooth, no rust, no scaling, small fluid resistance

5. PPR pipe has excellent insulation properties, can significantly reduce the vibration and noise caused by the flow of liquid.

6. PPR pipe energy consumption is only 20% of steel pipe; its thermal coefficient is also only 1/200 of steel pipe, reducing heat loss greatly.

7. PPR pipe is poor electrical conductor material, which can avoid galvanic corrosion phenomena.

8. With poor thermal conductivity, PPR pipe can reduce condensation.

9. PPR pipes, fittings are recyclable.

Application

1. Hot and cold drinking water supply system of civil and industrial buildings

2. Clean, pure water piping system

3. Beverage production and transport systems

4. Industrial liquid delivery system

5. Central air conditioning system

6. Hot water circulation Heating System

7. Compressed air piping system

8. Garden and greenhouse irrigation systems

Material properties of PPR

PPR Physical properties: generally, the flexibility of the ratio of random PP copolymer is better than that of PP homopolymer, and the rigidity of them are in contrast. When the temperature dropped to 32 ° F, they can maintain moderate impact strength, and when the temperature dropped to -4 ° F, the usefulness will be limited. Flexural modulus (1% secant modulus of strain) of the copolymer is in the range of 483 ~ 1034MPa, and the homopolymer in the range of 1034 ~ 1379MPa. Effect of molecular weight PP copolymer material is not as rigid PP homopolymer large. Izod notched impact strength is generally in the 0.8 to 1.4 foot-pounds / inch.

PPR Chemical properties: PP random copolymer acid. Alkalis, alcohols, low-boiling hydrocarbon solvents and many organic chemicals have a strong resistance. At room temperature, PP copolymers are essentially insoluble in most organic solvents. Moreover, when exposed to soap, lye soap. Aqueous reagent and alcohols, they do not like many other polymers that would occur environmental stress cracking damage. When in contact with certain chemicals, especially liquid hydrocarbons, Chlorinated organic and strong oxidizing agents, can cause surface cracks or swelling. Non-polar compounds are generally easier than the polar compounds absorbed polypropylene. The molecule only carbon, hydrogen, no harmful toxic elements exist.

PPR Barrier properties: PP homopolymer and copolymers have a very low water vapor permeability (0.5 g / cc / 100 square inches / 24 hours). These properties can be improved by orientation. Stretch blow molded polypropylene bottles Yiba resistance to water vapor permeation performance improvement to 0.3, the oxygen permeability of 2500.

PPR Electrical properties: Generally, polypropylene has good electrical properties, including: high dielectric strength, low dielectric constant and low dissipation factor; however, power applications usually selected homopolymer.

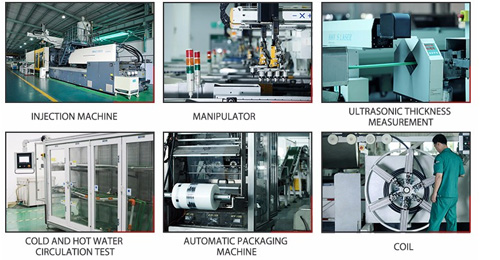

PP-R pipe production process is extrusion process, first add PP-R raw material in the hopper by gravity into the extruder in the extruder barrel heated extrusion mixed and fully plasticized from the extruder mouth die extruded into stereotypes, stereotypes of the pipe after by tractor, measured by length, cut by the cutting machine, after passing the test tube after storage. Corresponding pp-r pipes and fittings are produced by injection molding.

Polyethylene pipe production process: PP-R raw materials → vacuum suction hopper send feed storage → extrusion → cooling stereotypes traction → cutting → inspection → warehousing pipe production process: PP-R materials → feeding conveyor → storage hopper feed heating and melting → cooling and molding injection extrusion mold → inspection → warehousing.

Pipe Extrusion parameters: (1) a screw speed of 5 ~ 38r / min (2) barrel temperature profile of 1 to Zone 2 180 ~ 190 ℃ 3 ~ 4 region 200 ~ 210 ℃ mold temperature of 200 ℃ traction speed 2 ~ 20m / min Tube injection parameters: 200 ~ 230 ℃ front barrel portion (1) cylinder barrel temperature profile 160 ~ 170 ℃ rear central cylinder 180 ~ 200 ℃ (2) of the nozzle 170 ~ 190 ℃ (3) 40 ~ 80 ℃ PP molds -R pipe production process defective products, after crushing can be used again, which improves utilization of raw materials, and reduce production costs, improve economic efficiency.

- Q: Can plastic tubes be used for crafts or DIY projects?

- Yes, plastic tubes can be used for crafts or DIY projects. They can be cut into various lengths and shapes, painted, decorated, and glued together to create a wide range of creative projects such as pen holders, flower vases, organizers, or even small sculptures. The versatility and durability of plastic tubes make them a popular choice among craft enthusiasts and DIYers.

- Q: Can plastic tubes be used for chemical dosing?

- Yes, plastic tubes can be used for chemical dosing. They are commonly used in various industries such as water treatment, pharmaceuticals, and agriculture. Plastic tubes are resistant to corrosion, lightweight, and cost-effective, making them suitable for safely transporting and dispensing chemicals in controlled dosages.

- Q: Can plastic tubes be used for aquariums?

- Yes, plastic tubes can be used for aquariums. They are commonly used for various purposes such as connecting filters, air pumps, and other equipment to the aquarium. However, it is important to ensure that the plastic tubes used are safe for aquatic life and do not release any harmful substances into the water.

- Q: Wire sets, plastic tools, what tools bend?

- With something that looks like a spring.

- Q: I was changing my engine oil via the dipstick tube and a special suction device that pumps the old oil out of the sump to be replaced with fresh oil. Unfortunately, i had to patch up a hole in the tube on the suction device with parcel tape/sellotape wrapped around and a small piece of tape (around 2x2 square) fell into the engine dipstick tube and appears to have slid down into the oil sump.Will the oil filter make any difference in keeping melted plastic out of the engine? Am i best calling up the manufacturer, not the dealer as i don't want them to know about my error. The engine still runs and i have driven 20 miles so far with no problems. 2009 year Citroen C1Thanks

- This is worrisome. As the others say, the worst scenario is the tape gets against the pickup screen and suddenly causes loss of oil pressure. If that happens you will immediately get a low oil pressure warning light but that's something you don't want to happen anyway. However since the piece of tape is 2 x 2 or thereabouts at this point it is almost certainly still rolled up and stuck at the bottom of the dipstick tube. There would not be room for it to easily escape and fall into the sump… yet. There should be one or two screws at the bottom of the dipstick tube to secure it to the engine. If you remove those screws and pull the dipstick tube out, with the dipstick unit, you should find the tape at or near the bottom of the tube. Remove the tape, throw it away, put the tube back in, and sin no more.

- Q: Have an 01 Nissan Sentra and the dipstick handle broke of and while trying to get the dipstick out it got pushed in about 3-4 inches. How do we get it out? Is it safe to move the vehicle while its in there? Please help thank you.

- remove the oil and oil sump,then u can remove broken dipstick bottom form the oil sum

- Q: Is the PVC tube a plastic tube or a plastic tube?

- Is not flammable, high strength, excellent resistance to climate variability and geometric stability. PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons.

- Q: Do plastic tubes have any limitations in terms of compatibility with other packaging materials?

- Yes, plastic tubes do have limitations in terms of compatibility with other packaging materials. Plastic tubes may not be suitable for certain products that require specific packaging properties, such as those that are reactive with plastic or require oxygen or moisture barrier properties. Additionally, plastic tubes may not be compatible with certain closure systems or labeling methods used with other packaging materials.

- Q: Are plastic tubes suitable for use in the electronics industry?

- Yes, plastic tubes are suitable for use in the electronics industry. They are lightweight, cost-effective, and have excellent insulating properties. Plastic tubes can be used for cable management, wire harnessing, and protecting delicate electronic components. They are also resistant to chemicals, moisture, and UV radiation, making them a reliable choice in various electronic applications.

- Q: What are the advantages of using plastic tubes in the pharmaceutical industry?

- There are several advantages of using plastic tubes in the pharmaceutical industry. Firstly, plastic tubes provide a high level of hygiene and safety as they are non-reactive and do not interact with the contents of the tube, ensuring the purity and integrity of the pharmaceutical products. Secondly, plastic tubes are lightweight and highly portable, making them ideal for transportation and distribution of pharmaceutical products. Additionally, plastic tubes are cost-effective compared to other materials, allowing for efficient production and lower manufacturing costs. Lastly, plastic tubes offer versatility in terms of size, shape, and functionality, enabling customization to meet specific pharmaceutical packaging requirements.

Send your message to us

China PPR Pipes and Fittings for Hot and Cold Water Conveyance with Safety Guaranty

- Loading Port:

- Tianjin

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 m

- Supply Capability:

- 250000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords