Plastic Sheets - China Manufacture Lightweight 33mm PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Technical data sheet:

| inspection items | unit | standard | standard |

| L-600 | L-1100 | ||

| test results | test resuts | ||

| density | kg/m3 | ≥115 | ≥90 |

| tensile strengh | mpa | ≥1.0 | ≥0.9 |

| beark strength | kg/m2 | ≥6.5 | ≥3.5 |

| compression strengh | kg/m2 | ≥150 | ≥130 |

| permanent distortion at pressure | % | ≥0.9 | ≥0.7 |

| elongation | % | ≥80 | ≥70 |

| water absorption | g/m3 | ≤7 | ≤8 |

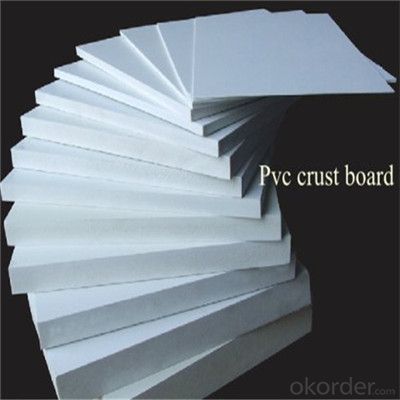

Features:

--low water absorption rate

--good elasticity, low compression permanent distortion

--closed cell structure, can contact and bond well with concrete

--resistant to water flushing

--high / low temperature resistant

--chemical and aging resistant

Performace of material

1. The product has the same processing performance, can nail, drilling, cutting, bonding, with a nail or bolt connection fixation, smooth surface, no need to sanding and paint, the paint adhesion also according to individual be fond of painting.

2.Better than wood dimensional stability,can be coated or composite colorant surface can be made of brilliant color, so no need to timely maintenance.

3. A variety of specifications, size, shape and thickness of the demand, which also includes a variety of design, color and grain products, provide more choices to customers.

4.The product is fireproof, waterproof, corrosion, resistant to moisture, not moth eaten, non-toxic, no pollution and other excellent performance, low maintenance cost

5 The use of products have similar wooden appearance, high hardness than plastic, long life, thermoplastic molding, high strength, saving energy

6.Light weight, heat preservation, smooth surface, no formaldehyde and other harmful substances, no poison, no pollution

Surface: printing color, can be coated or made of a variety of colors, with flame retardant, moisture, acid and alkali, long life, high strength, non-toxic, anti-aging ability, can be hot forming and so on;

Q: What's the PVC Foam Sheet Processing performance?

A: 1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

Q: How many colors you have?

A: We have more than 100 existed colors. We can send the color swatch if you leave your message. Also customized colors are acceptable.

- Q: They need to be non-adhesive.

- Spray it with acrylic wax

- Q: Which type of glue or past to past 2 plastic sheet.{ recycle sheet}to start a small Business

- We need to know what you're going to do with the plastic sheets and what type of sheets they are. Different glues for different requirements.

- Q: Can plastic sheets be cut to custom sizes?

- Yes, plastic sheets can be cut to custom sizes.

- Q: Can plastic sheets be used as a replacement for glass in windows?

- Yes, plastic sheets can be used as a replacement for glass in windows. Plastic sheets such as acrylic or polycarbonate offer advantages such as being lightweight, shatterproof, and having good insulation properties. However, they may have a lower optical clarity compared to glass and can be prone to scratching. Additionally, they may have different heat resistance capabilities that should be considered for specific applications.

- Q: I have a 30 gallon plastic bucket that I cut a large square out of it and I have molded the acrylic sheet to the right shape, but is there anyway I can bond the acrylic to the plastic? It needs to be water proof and not leech any chemicals. It will be filled up with water and will hold some fish.

- All the plastic buckets I've seen so far are from PA, PP or PE - plastics chosen for their chemical inertness, which in turn also means that they're d*mn near impossible to glue (pretreatment with hot concentrated nitric acid is among the more accessible methods....). As is acrylic, btw. You might be able to weld them (chemically or thermally), but I wouldn't trust this weld if I did it for the life of the fish. If the overlapping area is large enough and the acrylic sheet goes on the inside of the bucket (so that the water pressure actually compresses the seam), you might try fish tank silicone. It won't really glue the parts together, but might stick well enough (probably until someone tries to poke it :-( ). But I doubt that you'll get that stuff in oe of the big box stores - ordinary builder's silicone or bathroom silicone are no good - they'll leach acetic acid and, in case of bathroom silicone, fungicides.

- Q: I have started sewing checkbook covers recently. They seem to need something to stabilize them, and I have been using cardboard. I was wondering if anywhere sells thin plastic sheets (like margarine/yogurt lid thickness) that I could cut to fit. I don't sew through it, it would be removable. Or somewhere online would work too.... or any suggestions to use stuff I already have! Thanks for your help! :)

- Plastic canvas works well for that. Michaels and Hobby Lobby both have it.

- Q: I suppose with an election just around the corner I better hold on to them...

- Hold on to them just in case.

- Q: How do you remove the plastic block from the kitchen?

- The wooden cutting board of high density, strong resilience, strong because the wooden chopping board easy to choose some wooden boards (BIOU cypress) containing toxic substances and odor pollution in vegetable dishes and can cause vomiting, abdominal pain, faint symptoms some loose poplar wood chopping board board easy to crack the surface hardness is enough to cut clean easy to shelter evil people and countenance evil practices. Recommended to choose the recommended food contamination material

- Q: In school we're making an experiment where you're going to put plastic sheet over for example a pear put not the top. When i did the experiment it seems like plastic sheet won't let the microwaves in, can someone explain to me why?

- If you are coming to that conclusion, there is something very wrong with your experimental methodology. Without more detail, it's fairly pointless to speculate what the problem may be.

- Q: I am making paintings (fine art) that can be painted and lifted like large decals. I have used 6 mil shipping plastic, This works great, but is hell to format and non-permanent. I need to identify and locate a more stable substitute. (Clear plastic sheeting; large solid sheets that watersoluble paint will peel off of.)I would think the same thing tupperware is made of (polypropylene), but cannot find it in flat clear sheets. Does anyone know what the clear painters pallettes are made of (melamine?) and if it is sold in sheets to the public? I have been trying to put a finger on this for over 2 years--any help or leads out there?thanx

- try some of your local sign painters. They have a lot of strange plastic sheets that they do signs on. I buy one type that you can stick to a car window and remove. I put signs on them so I can remove and reapply. That might even work. You could adhere it to a piece of glass ...do your paint application....let it dry and then remove. Mylar from an art supply might work...

Send your message to us

Plastic Sheets - China Manufacture Lightweight 33mm PVC Foam Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7000 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords