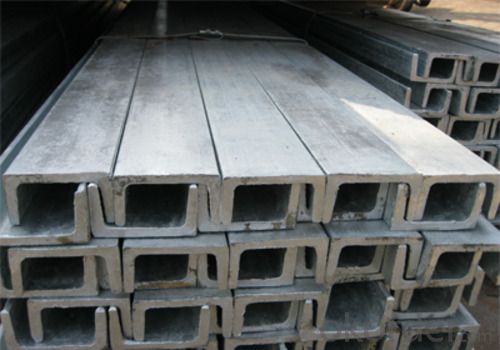

Channel Steel Bar Hot Rolled 100x50x5.0 mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Channel Steel Bar Hot Rolled 100x50x5.0 mm at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Channel Steel Bar Hot Rolled 100x50x5.0 mm are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Channel Steel Bar Hot Rolled 100x50x5.0 mm are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

Channel is the cross section for the groove shape of strip steel.For slotted steel cross section shape.Channel steel building use and mechanical use carbon structural steel, is a complex section steel, steel its section shape is hollow.Channel steel is mainly used for building structure, curtain wall engineering, mechanical equipment and vehicles manufacturing, etc.In use for its good welding, riveting performance and comprehensive mechanical properties.Of channel steel billet raw material for carbon content less than 0.25% of the carbon steel or low alloy steel billet.Channel steel common channel steel and light channel steel.Hot rolling of the specifications of the common channel for # 5-40.The supply and demand both sides agreement to supply hot rolled flexible channel steel specification to 30 # 6.5.Channel steel is mainly used for building structure, vehicle manufacturing, and other industrial structure and the fixed plate of tank, etc., channel steel is often used and beams.Channel according to the shape and can be divided into four kinds: cold bending equilateral channel steel, cold bending unequal channel steel, cold bending edge channel steel, cold bending edge channel according to the theory of steel structure should be force, channel steel flange is channel steel should be standing, not lying down.

· Professional Service

· Competitive pricing

Product Specifications:

1.product name:channel steel

2.size:50*37*4.5mm-400*104*14.5mm

3.length:6m 12m

4.standard:GB JIS UPN UPE

5.Specification

Product Name | S235JR S355JR SS400 A36 Q235 Q345 u beam section hot rolled iron beams u channel |

Standard | JIS AISI ASTM GB DIN EN10025 |

Grade | Q235;Q345;SS400;ASTM A36 ;S235,S355 |

Size | 50*37*4.5mm---400*104*14.5mm |

Length | 6m,9m,12m,or cut the goods to the clients’ request |

Surface Treatment | Galvanized;Paint;or according to customer's request |

Shape | C or U |

Package | Seaworthy packing or as the customers’ requirement |

Application | Construction ,shipbuilding ,machine-made household industry |

Trade Term | FOB CNF CIF |

Payment | T/T L/C |

Loading Port | Tianjing |

Delivery Time | 7-15days,or as per your request |

Report | Material report ,Mechanical performance report |

Certification | ISO,EN 3.1,SGS |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:How do steel channels perform in terms of wind resistance?

- Steel channels perform very well in terms of wind resistance. Their structural design and material strength allow them to withstand high wind loads without significant deformation or failure. This makes steel channels a reliable choice for applications where wind resistance is a critical factor, such as in the construction of high-rise buildings, bridges, or wind turbine towers.

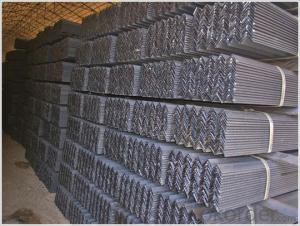

- Q:What is the difference between channel steel and angle steel?

- The cross section of the channel steel is concave, and the cross section of the angle steel is L, forming a 90 degree angle

- Q:What are the different load capacities of steel channels?

- The load capacities of steel channels may vary due to factors like channel size, shape, steel type, and installation method. Nevertheless, steel channels are generally recognized for their high load-carrying ability because of the inherent strength of steel as a construction material. Manufacturers and engineers typically determine the load capacities of steel channels through extensive testing and calculations. These load capacities are usually expressed as the maximum load that the channel can support safely without experiencing structural failure or deformation. To ascertain the load capacity of a specific steel channel, it is crucial to consider relevant design codes and standards. These guidelines provide instructions for calculating load capacities based on material properties, safety factors, and anticipated loads. It is important to note that load capacities may vary between different types of steel channels, such as C-channels, U-channels, and custom shapes. Other factors like channel length, span, fastener type and placement, and overall structural design can also influence load capacities. Ultimately, consulting with manufacturers, structural engineers, or reference design codes is essential to determine the specific load capacities of steel channels for a particular application.

- Q:Geometrical dimension of channel steel channel 8

- GB material. Now a lot of non-standard (lower tolerance. National standard difference 5~7%)

- Q:What are the different alloy compositions available for steel channels?

- There are several different alloy compositions available for steel channels, each with its own unique properties and advantages. Some common alloy compositions include: 1. Carbon Steel: This is the most basic and widely used type of steel. It contains primarily iron and carbon, with small amounts of other elements. Carbon steel channels offer good strength and durability, making them suitable for various applications. 2. Stainless Steel: This alloy composition includes iron, chromium, and nickel. Stainless steel channels are highly corrosion-resistant and have excellent strength and heat resistance. They are commonly used in environments where resistance to rust and staining is crucial, such as in the food industry or marine applications. 3. Alloy Steel: This composition includes iron, carbon, and other alloying elements such as manganese, chromium, or molybdenum. Alloy steel channels offer enhanced strength, hardness, and wear resistance compared to carbon steel. They are often used in applications requiring high tensile strength, such as construction, automotive, or machinery manufacturing. 4. High-Strength Low-Alloy (HSLA) Steel: HSLA steel channels contain small amounts of alloying elements like copper, vanadium, or niobium. These alloys enhance the strength and toughness of the steel while maintaining good weldability and formability. HSLA steel channels are commonly used in structural applications, bridges, or automotive components. 5. Weathering Steel: This composition includes iron, chromium, and copper. Weathering steel channels are designed to develop a protective rust-like coating when exposed to the atmosphere. This coating acts as a barrier against further corrosion and eliminates the need for painting. Weathering steel channels are often used in outdoor structures like bridges or building facades. It is important to select the appropriate alloy composition based on the specific requirements of the application, considering factors such as strength, corrosion resistance, weldability, and cost. Consulting with a materials engineer or steel supplier can help determine the most suitable alloy composition for steel channels.

- Q:Can steel channels be used in the marine industry?

- Yes, steel channels can be used in the marine industry. Steel channels, also known as steel C-channels or structural channels, are versatile and widely used in various industries including the marine industry. They are commonly used for structural support, framing, and reinforcement in marine vessels, offshore platforms, docks, and other marine structures. Steel channels offer several advantages in the marine industry. Firstly, steel is a strong and durable material, capable of withstanding the harsh marine environment, including exposure to saltwater, waves, and extreme weather conditions. This makes steel channels ideal for providing structural integrity and stability to marine structures. Additionally, steel channels can be easily fabricated and customized to meet specific design requirements. They can be cut, welded, and formed into different shapes and sizes, allowing for flexibility in construction and design. This versatility is crucial in the marine industry, where structures need to be tailored to fit specific applications and specifications. Furthermore, steel channels have excellent load-bearing capacity, making them suitable for supporting heavy equipment and loads in the marine industry. They can be used as beams, columns, or bracing elements to distribute the weight and stresses evenly, ensuring the safety and stability of marine structures. Moreover, steel channels have good corrosion resistance when properly coated or protected. This is crucial in the marine industry, where structures are constantly exposed to saltwater, which can accelerate corrosion. By utilizing proper coatings or galvanization techniques, steel channels can resist the corrosive effects of seawater, prolonging their lifespan and reducing maintenance costs. In conclusion, steel channels are a viable option for the marine industry due to their strength, durability, versatility, and corrosion resistance. They are commonly used for supporting, framing, and reinforcing marine structures, contributing to the overall safety and longevity of these structures.

- Q:How do steel channels compare to other structural shapes like beams and angles?

- Due to their strength, versatility, and cost-effectiveness, steel channels, beams, and angles find widespread use in construction and structural engineering. Each of these structural shapes possesses unique characteristics and applications, rendering them suitable for various purposes. When comparing steel channels to beams and angles, it becomes crucial to take into account their load-bearing capacity, structural stability, and overall performance. Steel channels, also known as C-channels or U-channels, exhibit a distinctive shape characterized by a vertical web connecting flat top and bottom flanges. They are commonly employed in applications necessitating lightweight structural support, such as framing, bracing, or object securing. Steel channels excel in evenly distributing loads and providing sufficient support in multiple directions. Their versatility allows for seamless integration into diverse structural designs. On the other hand, beams typically possess an I-shape and offer superior load-bearing capabilities compared to channels. Their design enables them to handle higher loads across longer spans. Beams typically serve as primary structural elements in buildings, bridges, and other large-scale constructions. Thanks to their high strength-to-weight ratio, beams are ideal for withstanding bending and flexural stresses. Angles, comprising two perpendicular legs of equal or unequal lengths, manifest as L-shaped structural components. They primarily serve the purpose of providing additional structural support and reinforcement. Angles commonly find use as braces, corner supports, or lintels. Their versatility allows for easy connections and integration within a structure. In terms of cost, steel channels are generally more affordable compared to beams and angles due to their simpler manufacturing process and lower material requirements. However, the cost may vary depending on the specific dimensions, grades, and finishes required. Overall, the choice between steel channels, beams, or angles depends on the specific application, load requirements, span lengths, and design constraints. It is crucial to consult with a structural engineer or designer to determine the most suitable structural shape for a particular project.

- Q:What are the factors to consider when determining the appropriate thickness of a steel channel?

- When determining the appropriate thickness of a steel channel, several factors need to be taken into consideration. These factors include the load or weight that the channel will need to support, the span or distance between supports, the type of material being used, and any additional factors such as environmental conditions or safety requirements. By considering these factors, engineers or designers can ensure that the steel channel is of sufficient thickness to safely and effectively meet the intended purpose.

- Q:Duplex 3, the main beam 3.6 meters, span 4.5 meters wide, steel structure, with 8 channel steel can be, how much space? Or how to make it reasonable? Daily life bears little weight.

- How reasonable?. Have to tell you the plane of the room, how to do it, according to some careful design, and then you see the satisfaction of the design results signed and approved. It'll take a lot of time. I can't help you.

- Q:Can steel channels be used for creating support structures for conveyor systems?

- Yes, steel channels can be used for creating support structures for conveyor systems. Steel channels offer excellent strength and durability, making them suitable for supporting heavy loads and providing stability to conveyor systems. The rigid nature of steel channels ensures that the support structure remains intact and can withstand the constant movement and vibrations associated with conveyor systems. Additionally, steel channels can be easily fabricated to meet specific requirements and can be welded or bolted together to create a customized support structure for the conveyor system. Overall, steel channels are a popular choice for creating support structures for conveyor systems due to their strength, durability, and versatility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Channel Steel Bar Hot Rolled 100x50x5.0 mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords