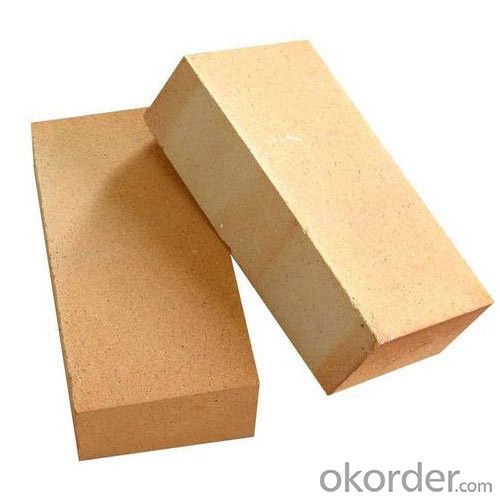

Fireclay Brick - Chamotte Fireclay Fireproof Refractory Bricks SK32/SK34/SK36/SK38

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

It is widely used in metallurgy, petroleum, chemical industry, building materials,

machinery processing, military, etc of thermal technology equipment.It is widely

used for MgO Reduction Furnace, Blast furnace, Hot Blast Stove, Tunnel kiln ,

Steel Ladle,Steel smelting furnace, Coke oven,chimney,Waste incinerators ,Casting

products,Boilers, Cement kilns, Carbon furnace, Glass kilns and a variety of furnace

linings and thermal equipment.etc.

Products data:

ITEM | SK-32 | SK-34 | SK-36 | SK-38 |

Al2O3(%)Min | 35 | 38 | 48 | 65 |

Fe2O3(%)Max | 3.00-4.00 | 2.50 | 2.00 | 2.00 |

0.2Mpa Refractoriness under load (°C) Min | 1300 |

1350

|

1450

|

1500

|

Apparent porosity(%) | 22-26 | 20-24 | 20-23 | 20-22 |

B.D(g/cm³)Min | 2.05-2.10 | 2.10-2.2 | 2.25-2.35 | 2.40-2.50 |

Cold crushing strength Mpa | 22 | 25 | 45 | 50 |

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: How to choose the proper refractory bricks when buying the refractory bricks?

- Crack condition. 4. 6. Inspection of dimensions. Conditions of pits and swells and lack of edges or angles. The inspection of refractory bricks' appearance quality and the condition of the affecting with damp.

- Q: What is the meaning of special shaped refractory brick material n-2b?

- In fact, there are many kinds of refractory bricks, titanium, high alumina refractory brick, after drying. The mineral composition of the clay brick is mainly kaolinite (Al2O3·2SiO2·2H2O) and 6% ~ 7% impurities (K, etc.). Clay refractory bricks are iron oxide sintered by 50% soft clay and 50% hard clay clinker ingredients according to a certain granularity requirements under the high temperature of 1300 ~ 1400 degrees), perlite

- Q: Can you direct the clay brick walls embryo

- Must not。 Not damp, damp, air tight, poor pressure bearing, bad adhesion between bricks and bricks

- Q: what is application of high alumina refractory brick?

- reverberatory?furnace 1, close to the neutral refractory, but because mullite crystallization has not formed the network organization, so the load softening temperature is not higher than silica?brick. the refractoriness of high alumina brick is higher than fireclay?brick and semi-silica brick, mainly used in blast furnace, nozzle brick,etc. it is up to 1790 C~ 1750, can resistance to acid slag and alkaline slag erosion. hot blast furnace, blast furnace, high alumina brick are widely used for producing open-hearth?furnace regenerative bricks, because it contains SiO2, low impurity content, which belongs to high-grade refractory materials, electric furnace. 2, plug head used in pouring system . In addition. 3, because high aluminum products contains more Al2O3, forming less fusible vitreous body, so the high load softening temperature is higher than clay brick. because rotary kiln lining, slag resistance of high alumina refractory brick contain more Al2O3, so the ability of anti alkaline slag is weaker than anti acid slag. so it has a wide range of application. high alumina refractory brick due to the following performances

- Q: Whether fireclay raw materials or clinker are used when masonrying general fireclay?brick? What is the difference between raw material and clinker?

- Generally, refractory bricks use clay refractory mortar, raw material and clinker are halves

- Q: What is the perservation method for refractory bricks used for cement kiln?

- The place should be dry and ventilated. Remember that the packaging can't be damaged. If is not used for a long time, put desiccant next to the bricks. Then have thermoplastic packaging again, it won't get damp. Under normal circumstances, it can be stored for 3-5 years and won't be hairy

- Q: What type of refractory brick won't deform or crackbe for a long time in the temprature of about 1600 degrees?

- 1. , mullite poly light ball brick type, andalusite brick type: MJ-1600 MJ-1700 the temperature is higher than 1600 C. 3, the refractory bricks that won't deform or crack in the 1600 degrees Celsius for a long time includs the following several commonly used bricks: GMZ-80 GMZ-75 the temperature is higher than 1650 DEG C, 2, corundum mullite brick type

- Q: what type of refractory bricks does TZ-3 stands for ?

- Z stands for the straight brick, T stands for general brick. general straight shaped standard brick, -3 is the length, specification is 230*114*65 (mm)

Send your message to us

Fireclay Brick - Chamotte Fireclay Fireproof Refractory Bricks SK32/SK34/SK36/SK38

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords