Ceramic Fiber Bulk - Pure White Thermal Insulation Spun

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is the Ceramic Fiber Spun Bulk?

l Ceramic fiber spun bulk is the optimal material for the production of fiber textile and also the perfect material for sealing, filling and insulating in high-temperature environment.

l Ceramic fiber spun bulk is loose, long and flexible with high refractory properties and great for energy saving and/or high temperature insulation.

What are the Great Characteristics of Ceramic Fiber Spun Bulk?

Ceramic fiber spun bulk has the characteristics of stable performance, resistance to chemical attack, excellent thermal stability, clean and white color etc.

What are the Types of Ceramic Fiber Spun Bulk?

Ceramic fiber spun bulk are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃, 1100℃, 1200℃ and 1350℃.

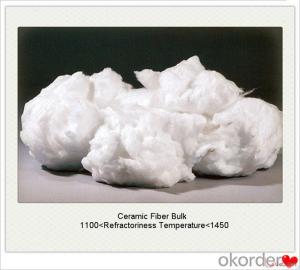

Images of Ceramic Fiber Spun Bulk?

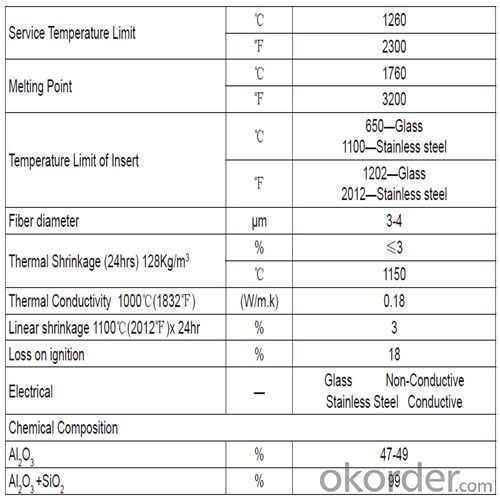

Technical Data of Ceramic Fiber Bulk

What is the Typical Applications of Ceramic Fiber Bulk?

Ceramic fiber bulk for textile manufacture

Expansion joint packing

Wet process feedstock

Filtration media

Kiln car infill

Moldables / Mastics feedstock

Ladle insulation

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Energy saving: ordinary furnace heat loss, heat rate, furnace insulation can. The holding time of ceramic fiber furnace is ten times higher than that of ordinary furnace, and it is easy to quench and quench.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q: Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber length: fiber rejection is longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;

- Q: Is aluminum silicate fiber poisonous?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton. In the whole process of production, it can be found that the raw material does not contain toxic substances. Compared with asbestos, it is a substitute product of asbestos and contains no carcinogens.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- If the above two kinds of roller blinds, really true to do, the former per square meter at least 500 yuan, and the latter at least 400 yuan per square meter. Otherwise, there must be a problem.

Send your message to us

Ceramic Fiber Bulk - Pure White Thermal Insulation Spun

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords