High Tensile Strength Ceramic Fiber Paper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes . It is featured with high temperature resistance and heat insulation and high anti-melt capability, very low thermal conductivity, chemical corrosion resistance and thermal shock stability.Product coverage areas including petrochemical industry, steel industry, aluminum industry, metallurgy industry.

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

Industial thermal insulation and sealing corrosion resistance material, such as industrial furnace and steel pipe or metal casting

Thermal and electiical insulation meterial

Instrument equipment inslution material

Kiln cr deck covering for insulaiton

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

Low thermal conductivity , low thermal capacity,and excellent thermal insulation property.

High chemical stability ,resistance to corrosion ,excellent eletric insulation property

Good flexibility and toughness,easy to cut or install quickly

Good thermal stability and resistance to thermal shock.

Good sound absorption and mechanism strength

Non-asbestos,low slag ball content

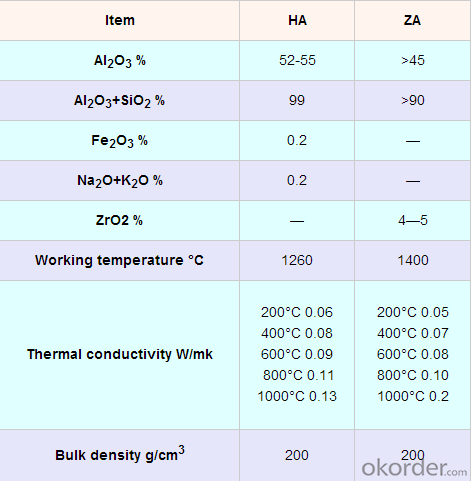

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

- Q: Expert answer. What is the difference between ceramic fiber paper and ceramic fiber cloth?

- 1, appearance. Ceramic fiber cloth (HLGX-208A1/HLGX-208A1) ceramic fiber yarn textile woven by warp and woof formed with grid, the grid was bigger; the ceramic fiber paper (HLGX-236) vacuum suction molding, there is no grid.2 density. Ceramic fiber paper density 200Kg/m ceramic fiber cloth density fand, 500Kg/m fand, ceramic fiber paper than ceramic fiber cloth density.3, thickness. Ceramic fiber paper, the thinnest can do 0.5mm, the thickest 10mm, ceramic fiber cloth thickness is limited, in general the thinnest also have 2mm, the thickest 5mm.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- I used to work in the ceramic fiber factory for two years, and the main contact was fiber. There is not much contact with paper products and so is the understanding of fiber paper.The use of heat insulation material can not be considered temperature, as well as environmental, economic, atmosphere and many other factors to consider.

- Q: What's the fire resistance of the ceramic fiber?

- The most important index of porcelain refractory fiber is the diameter and thermal stability of the fiber. Al2O3SiO2 fiber is commonly used in ceramic industry. It is divided into different application range according to the content of Al2O3, and Cr2O3 material is introduced into it to improve its refractory and oxidation resistance. Generally high alumina content, iron oxide and other impurities of low fiber products are pure white, the introduction of chromium oxide fiber is sold with milk yellow tone color. The average diameter of the ceramic fiber is 24 microns. High fiber, small density, low thermal conductivity, high temperature. If the fiber is coarse and dense, the use is not satisfactory. The thermal stability index of fiber is more important. Al2O3-SiO2 fiber products range between 1260 and 3588% in line shrinkage. The amount of shrinkage is also directly related to thermal stability.

- Q: Ceramic fiber spray and thrown silk floss, which is better?

- With the blowing of thrown silk cotton is two kinds of refractory ceramic fiber cotton cotton in the market at present, according to different production process is defined. Because of the different process, the characteristics of the two kinds of fire-resistant cotton are also different. According to different characteristics, they are applied in different heat insulation fields respectively. Ceramic fiber cotton, also known as aluminum silicate fiber cotton, its main purpose is to use other forms of refractory products, production and processing of raw materials.

- Q: Do ceramic fiber paper smell at high temperature?

- If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- In recent years, due to the global energy prices continue to rise, energy saving has become a China national strategy background, than the insulation bricks and other traditional refractory pouring material such as 10-30% ceramic fiber has been used more widely in the domestic more Chinese, development prospects are very promising.

- Q: What are the features of ceramic fiber gaskets?

- Mifso-11 ceramic fiber gasket is Xin Xing sealing material factory is composed of ceramic fiber products through precise cutting, punching, die stamping process (part of the product after ultra high pressure adhesive bonding) produced.

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- The advantages of carbon fiber are light, excellent corrosion resistance, good elasticity and outstanding vibration absorption effect. The disadvantage is that the shock resistance is poor and the high temperature resistance is poor. It is used in a lot of planes, boats, sporting goods, such as bicycles, tennis rackets and so on. But the price is much more expensive than aluminum alloy.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

Send your message to us

High Tensile Strength Ceramic Fiber Paper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords