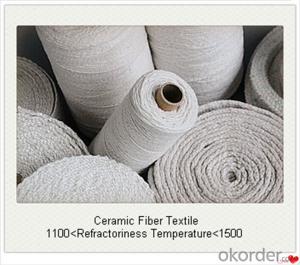

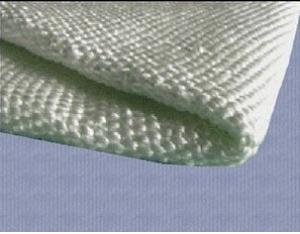

Ceramic Fiber Textiles - Lightweight Woven Ceramic Fiber Cloth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Characteristics of Ceramic Fiber Cloth

Low thermal conductivity, low heat storage, high temperature stable, thermal shock resistant

Fire and flame proof

Chemical resistant, compatible with most corrosive chemicals, commonly used acid and alkali (exceptions are hydrofluoric, phosphoric acids and concentrated alkalis)

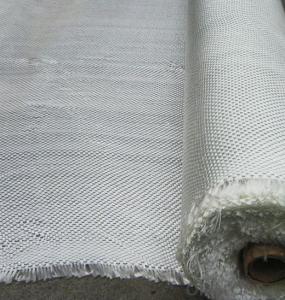

Lightweight, woven texture with excellent handling strength,

Size of Ceramic Fiber Cloth

Thickness: 2mm-10mm (2/25”-3/8”)

Feature of Ceramic Fiber Cloth

Low thermal conductivity

Low heat storage

Excellent chemical stability

Excellent thermal shock resistance

Excellent sound absorption

Application of Ceramic Fiber Cloth

Barrier to prevent fire spreading

Welding curtains and blankets

Furnace curtains,

High temperature electricity insulation

Cable and fuel line protection

Fireproof wrap, etc

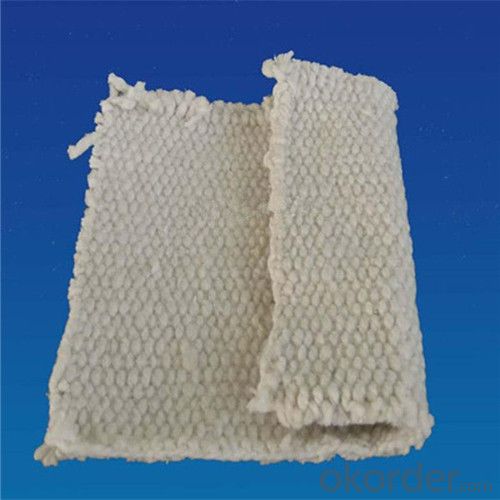

Image of Ceramic Fiber Cloth

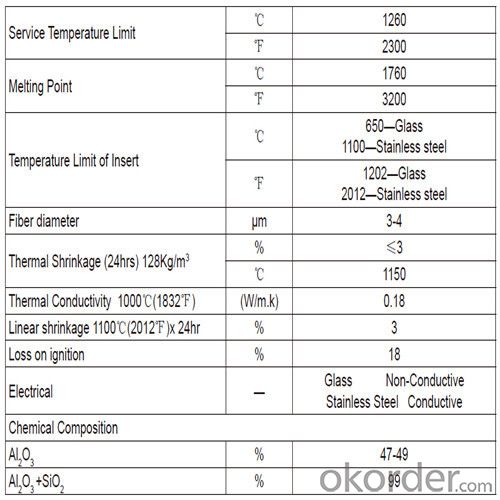

Technical Data of Ceramic Fiber Cloth

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q: What is the function of (ceramic) ceramic powder?

- In the process of porcelain fused to metal (PFM), the powder material used for sintering and making ceramic restoration is made. There are long stone and alumina ceramic powder, as well as a variety of crystal reinforced porcelain powder, high temperature porcelain powder and low temperature porcelain powder.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q: What are the differences between digital textile printing ink and printing ink?

- 3. acid ink:Suitable for jet printing of silk, wool and nylon;4. coating ink:Suitable for direct printing of all textiles.

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q: Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

Send your message to us

Ceramic Fiber Textiles - Lightweight Woven Ceramic Fiber Cloth

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 10000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords