Ceramic Fiber Textiles Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

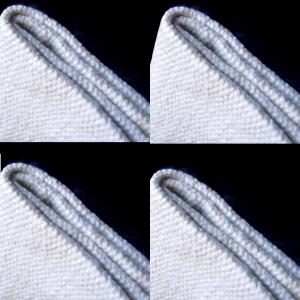

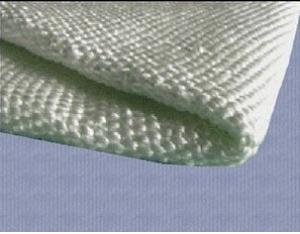

General Information of Ceramic Fiber Yarn

Ceramic fiber yarn is manufactured from high quality alumina-silica ceramic fiber and has been mechanically twisted to give it tensile strength. ceramic fiber yarn is available as E-glass or stainless steel #304 or #310 wire reinforced yarn from 425 tex to 2500 tex in single, two or three plies.

Ceramic fiber yarn can be woven, plaited into numerous forms of products which are strong, chemically stable and exhibit superior thermal properties, ideal for most industrial high temperature applications.

Product made of ceramic fiber yarn resist attack from most corrosive agents, except hydrofluoric, phosphoric acids and concentrated alkalis.

Feature of Ceramic Fiber Yarn

Low thermal conductivity

Low heat storage

Excellent chemical stability

Excellent thermal shock resistance

Excellent sound absorptio

Application of Ceramic Fiber Yarn

High Temperature gaskets

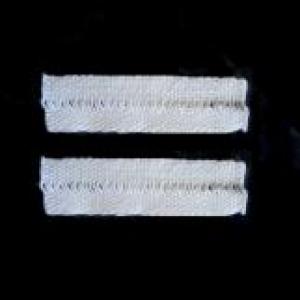

Production of cloth, tape

Sewing thread for high temperature textiles

Technical Data of Ceramic Fiber Yarn

|

|

CERAMIC FIBER TEXTILES | |

|

|

Classification Temperature (℃) | 1260 |

|

|

Melting Point (℃) | 1760 |

|

|

Temperature Limit of Insert | Glass 650℃ |

Stainless Steel 1100℃ | |

|

|

Color | White |

|

|

Fiber Diameter (µm) | 3-4 |

|

|

Loss on Ignition (%) | 18 |

|

|

Thermal Conductivity(W/m.k) 1000℃ | <0.18 |

|

|

Linear Shrinkage 24hrs (%) 1100℃ | 3 |

|

|

Chemical Composition (%) |

|

|

|

Al2O3 | 47-49 |

|

|

Al2O3+ SiO2 | 99 |

|

|

Fe2O3 | 0.2 |

|

|

K2O+Na2O | 0.2 |

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q: What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- Ceramic fiber blanket is mainly used for high temperature, tough, self bearing high strength of the place, but also used for high airflow speed, mechanical destruction of large places. Ceramic fiber blanket can be used in these occasions.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- High temperature ceramic fiber cloth is made of ceramic fiber cotton, E-glass filament, high temperature resistant stainless steel alloy wire with a special process, high strength, good flexibility, high machinability, not only has high temperature heat insulation performance, has the flexibility of common textiles.

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- 1. appearance. The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.2. density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.3. thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.4. stand erect. Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. Ceramic fiber cloth is like the fabric used in our 5. lives. It's soft and doesn't stand upright.6. tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: Which is better, ceramic fiber or spray velvet?

- Ji'nan Huolong thermal ceramics limited liability company to help you analyze: thrown silk and spray cotton, which is better? Which process is more suitable for producing carpets? Fire dragon energy saving from the technical point of view is as follows:1, fiber diameter: rejection fiber more coarse, rejection filament fiber is generally 3.0-5.0 mu m, spinneret fiber is generally 2.0-3.0 mu m;2, the length of fiber yarn: rejection fiber longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;3, the coefficient of thermal conductivity: spray cotton fiber is lower than that of the thrown silk;4, the tensile and flexural strength: thrown silk because fiber thicker than that of spraying cotton;

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Organic glass comes from English Organic Glass. In recent years, in some areas the sheet is made of transparent plastic all are called organic glass, actually this is wrong, it refers to pure acrylic polymethylmethacrylate (PMMA) and the PMMA sheet material, called acrylic plate.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Asia;America; Africa; Europe; and so on |

| Company Certifications | Quality management system certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 21-50 pepole |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | About 230,000 square meters |

| No. of Production Lines | 37 lines |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Ceramic Fiber Textiles Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls kg

- Supply Capability:

- 10 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords