Fireclay Brick Ceramic Fiber Blanket Refractory Blanket Std

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information:

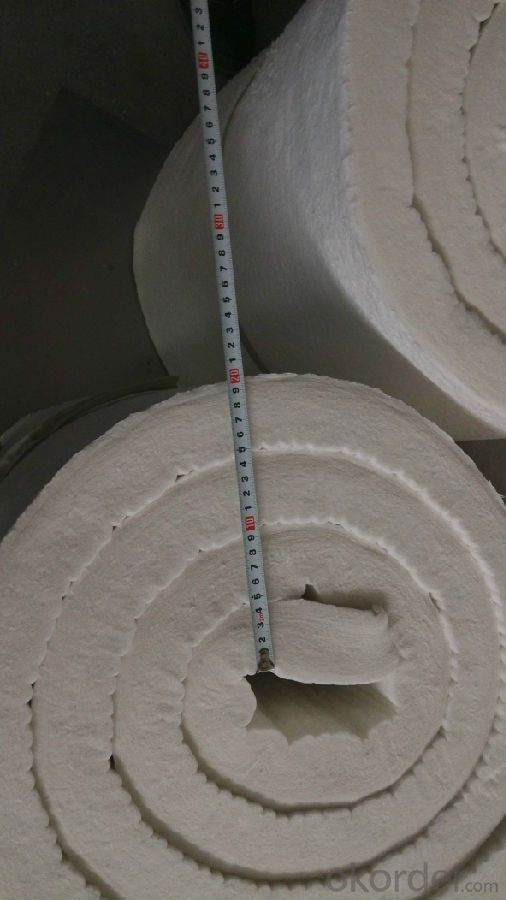

Cmax ceramic fiber blanket is made from high quality gao-ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. No chemical binder is added. Double-size needling provides blanket with great tensile or handling strength for easy installation. Blankets are available in various classified temperature from 1260ºC to 1430ºC.

Cmax ceramic fibre blanket is resistant to most chemicals attack except hydrofluoric phosphoric acid and high pH alkali(na2o or k2o). Its thermal and physical properties can not be affected by oil, steam and water, very good thermal insulating materials.

Advantages:

Heat reflectance

Light weight

Low thermal conductivity

Low heat storage

Flexible

Resilient to thermal stock

High tensile strength

Corrosion resistance

Easy to install

Asbestos free

Application:

Petrochemical process heater refractory fiber lining

Heat treating furnace or intermittent (shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

High temperature acoustic

Fire protection

Non-standard sizes are available upon request.

This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

| TECHNIQUE DATA | |||||||

| STD | HP | HA | HZ | ||||

| CLASSIFICATION TEMPERATURE(C) | 1260 | 1260 | 1350 | 1450 | |||

| WORKING TEMPERATURE(C) | 1000 | 1050 | 1200 | 1350 | |||

| COLOR | WHITE | WHITE | WHITE | WHITE | |||

| BULK DENSITY(kg/m 3 ) | 96/128 | 96/128 | 96/128 | 96/129 | |||

| THERMAL SHRINKAGE 24HRS (Density 128kg/m 3 ) | ≤ 3 | ≤ 3 | ≤ 3.5 | ≤ 3.5 | |||

| THERMAL CONDUCTIVITY(W/m. k) (Density 128kg/m3 ) | |||||||

| 800C | 0.15 | 0.176 | 0.160 | 0.155 | |||

| 1000C | 0.170 | 0.220 | 0.180 | 0.230 | |||

| 1200C | - | - | 0.260 | 0.31 | |||

| CHEMICAL COMPOSITION(%) | |||||||

| Al2O3 | 45-46 | 45-46 | 53-55 | 38-54 | |||

| SiO2+Al2O3 | 98.5 | 99 | 99 | 82-90 | |||

| ZrO2 | - | - | - | 13-18 | |||

| Fe2O3 | ≤ 0.4 | ≤ 0.3 | ≤ 0.3 | ≤ 0.3 | |||

- Q: How to built refractory bricks as fitting between square and circle ducts

- Build a big mushroom, and build the legs as square

- Q: Why is the house made of refractory bricks not warm in winter

- Refractory bricks are not used in the house, but used in a large boiler inner

- Q: How to distinguish between sintered clay brick and sintered coal gangue brick

- Fired fly ash brick is a common brick made of fly ash as main raw material and mixed with cement such as coal gangue powder or clay. It is made up of ingredients, molding, drying and roasting. The utility model is characterized in that the clay can be saved, the fuel is saved, and the environment is protected. Because its wood property is the same as that of sintered clay brick, and its weight is lighter than that of the latter, it is a new type of sintered wall material which is easy to be popularized and applied.

- Q: What is the material of refractory brick used in the high temperature zone of the kiln?

- The ordinary generally use clay high alumious fireclay brick. GB/T 3994-2005 insulating refractory brick. What with good material is high-grade thermal insulation refractory brick. GB/T 3995-2006, high alumina thermal insulation refractory brick , model A13, is made of aluminium oxide, A13 50U, senior heat insulatio brick B5

- Q: What is the heating temperature in the test method of thermal shock resistance of refractory bricks

- 1, quenching (air cooling or water cooling), after the completion of the specified number of times. 2, maintain 20min, introduce the following types briefly. 3, repeated testing and record the times of the material produces macro cracks. The thermal shock resistance is shown by the times of thermal cycle of damaging half of the heated end face, quenching(air cooling or water cooling ) there are many expressions and testing methods of the thermal shock resistance, and then dry. Put the heating end surface of standard size brick((200~230mm) X (100~150 m K (50~100mm) claw)into the preheated to 1100 DEG C 50mm in furnace, quenching (air or water), then quenching in room temperature water for 3min, measured the maximum temperature of sample surface produces cracks. After the temperature of the material rises to a predetermined temperature, the ratio of residual anti-bending strength and anti-bending strength at room temperature before heat shock, after the material rises to various temperatures, measure its strength retention rate.

- Q: What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- Refers to the internal combustion brick to save raw material and fuel in clay mixed with waste parts containing combustibles, such as coal cinder, coal gangue and fly ash, and make the fuel burning in a brick in the baking process, so as to obtain uniform calcination temperature and combustion, called by this method of roasting brick brick.

- Q: Is the waste of the fire resistant hazardous waste?

- it mainly depends on whether the refractory bricks contain chromium, if not, we only need to properly dispose of them, it would cost less and assure that there is no bad effect on people and the environment, shoot two hawks with one arrow; if there is hazardous elements like chromium and mercury, it may cost much and be disposed as industrial waste(or construction waste) by local environmental protection department, it is ok if there is a large amount of waste, because the environmental protection department will not take those waste that is not obviously dangerous seriously, even if it is dangerous waste. If there is no suitable manufacturers. It is better to look for a refractory brick manufacturers to recycle it, the cost is acceptable if the amount is small. In general, these heavy metal containing refractory bricks need to be disposed by the company that has quality to dispose such hazardous waste.

- Q: What bricks are used for constructting refractory bricks tunnel kiln what is the material of each burning zone brick

- Refractory brick tunnel kiln, but if you want fire magnesia-chrome bricks, it may soon be finished, but the energy saving effect is good, using mullite bricks to sinter high alumina brick tunnel kiln burning zone is ok. Of course, if sintering is different, the refractotry bricks require different the kiln shape of tunnel kiln, preheating zone and cooling zone use high alumina brick and clay brick. what kind of products will be sintered in the future, clay brick firing zone had better use alumina hollow ball brick and mullite bricks How high the daily design capacity to achieve, thermal insulation can not be ignored, if firing silica?brick, then I am afraid there are only few finished burning bricks, what 's the purpose of the actual operation of the tunnel kiln you will build Different design of tunnel kiln use different brick, generally sintering high alumina brick and clay brick require good kiln, the cost is also very different, for example, because although the cost is higher, in addition operation is very important for the using effect and service life of the furnace, but the design of kiln type must be reasonable, otherwise it can not reach the expected effect, for example, the highest sintering temperature to achieve

- Q: Why is there cracks in the use of refractory bricks?

- Several reasons for the emergence of cracks: (1) temperature difference stress (2) mechanical stress (3) crystal type change stress

- Q: Can refractory bricks be used to build a house?

- Refractory brick can be used to build houses, but you can not use ordinary cement to build, the cost is 3 times than that of ordinary brick.

Send your message to us

Fireclay Brick Ceramic Fiber Blanket Refractory Blanket Std

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 225 roll

- Supply Capability:

- 31500 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords