Ceiling Profile Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Our company specializes in manufacturing metal forming equipments with over 10 years in business.

All of them sell well in home and abroad, and are widely used in building materials, chemicals, metallurgical industry, electric power, coal, food, machinery, etc. We have established good reputation of quality and after-sale service.

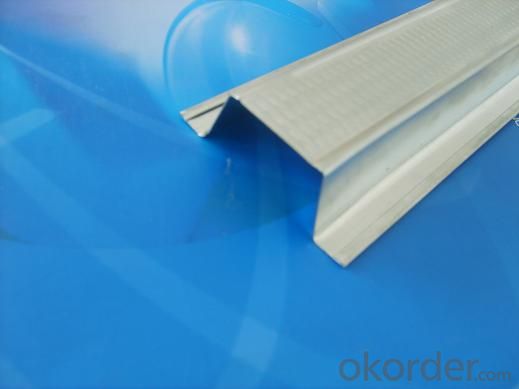

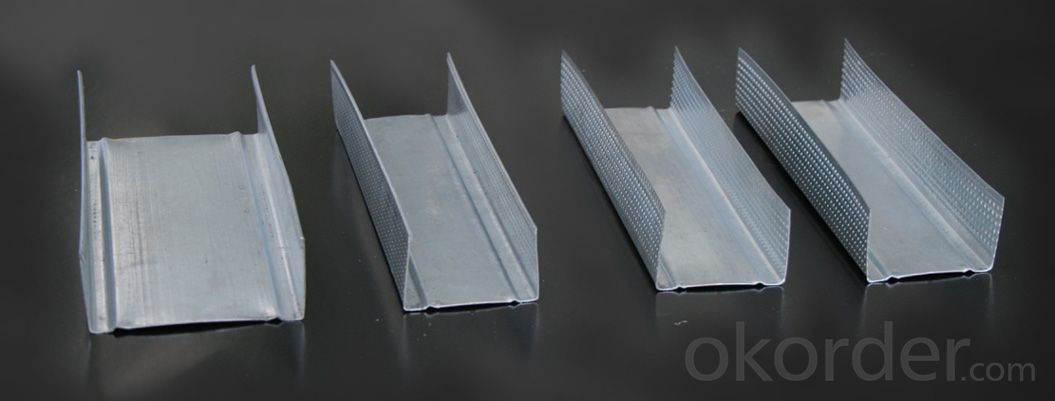

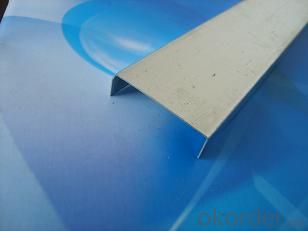

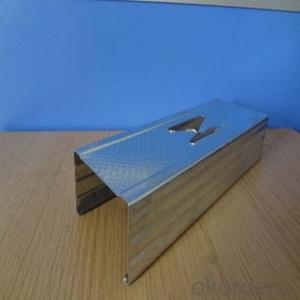

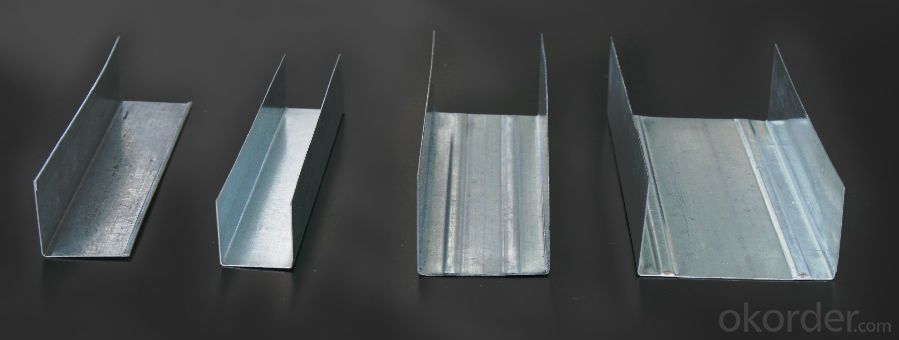

1.Type: Ceiling grid or drywall partition component

2.Thickness:0.4-1.2mm, size:42*25, 52*25, 72*25, 75*25, 100*34.5

3.Length: 2800mm, 3000mm, 3200mm

4.Light weight, high strength

5.Package:10pcs per bundle with plastic strip or iron wire

6.MOQ: 10 Tons, negotiable

7.Delivery time: T/T,

Feature and advantage

1)Rust proof

2)Corrosio-resistance

3)Multi-roll production technology

4)Fireproof, anti-seismic

5)Environmental friendly, Pls Be Assured Use

6)Easy installation, precisely dimensioned

3.Image

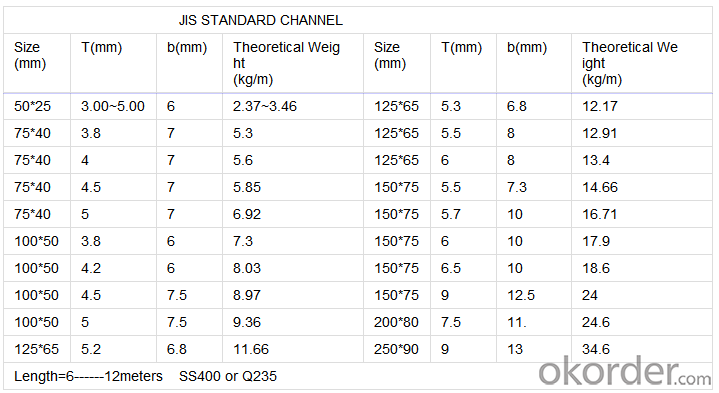

4.Detailed Specification

5.FAQ

Dry wall system install

1.To fix the ceiling track and the floor track to the clear ceiling and the clear floor with the shoot-nails.

2.Install the metal stud to the ceiling track and the floor track, and use the rivets to fix them in accordance with the design space.

3.The gypsum boards should be installed to the frame with the tapping screw, when the whole frame is formed .

4.One-layer gypsum board is used , the space between two gypsum plaster boards should be staggered. And the double-gypsum board is used the space between two gypsum plaster boards should also be staggered.

5.Joint putty process the final decoration can be done.

- Q: Light steel keel ceiling hanging bar spacing how much?

- 80-100cm or so, the light keel of the main keel and the keel have the quality of good or bad, so the intensity is different, the specific spacing as the case may be

- Q: What kind of thickness of the light steel keel there is no specification?

- I think the real construction of the main situation is to see the cost requirements, under normal circumstances with 0.7-0.8 centimeters on the

- Q: What is the yellow water to the keel brush before making the light steel keel ceiling?

- To prevent corrosion of light steel keel rust ah.

- Q: Is in accordance with the vice keel 400, the main dragon spacing 600 spacing arrangement?

- Light steel keel ceiling 400 * 600 meaning: the main keel and the distance between the main keel 600MM, vice keel and vice keel spacing of 400MM. Light steel keel ceiling, is that we often see the ceiling, especially the shape of the ceiling, are made of light steel keel frame, and then covered with gypsum board made. Light steel keel ceiling according to load is divided into human light steel keel ceiling and not on the light steel keel ceiling. Light steel keel according to keel section can be divided into: U-keel and C-keel. According to specifications can be divided into: D60 series, D50 series, D38 series, D25 series. Light steel keel, is a new type of building materials, with the development of China's modernization drive, light steel keel is widely used in hotels, terminals, bus stations, stations, playgrounds, shopping malls, factories, office buildings, old buildings Building renovation, interior decoration, roof and other places. Light steel (paint) keel ceiling with light weight, high strength, to adapt to water, shock, dust, noise, sound absorption, constant temperature and other effects, but also has a short duration, easy construction and so on.

- Q: Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- I think it Cost, light steel keel is more expensive than wood keel. Light steel keel is also divided into many kinds, it is recommended to use the national standard, the National Building Materials Testing Center of the test report is the real standard. GB price is not expensive, less than 20 yuan a square meter, non-standard cheaper less than 10 yuan a square meter. Own their own projects to their own good. Or cracking, deformation problems are very troublesome, the best step in place.is better to light steel keel

- Q: Construction schedule of light steel keel ceiling

- How much area? What shape? Elaborate

- Q: 140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q: Light steel keel and wood keel ceiling unit area of the amount of material how to calculate?

- Light steel keel ceiling ratio is: the main keel is 1: 1.1 (per square meter ceiling main keel is 1.1 meters), vice keel is 1: 3.5, the main hanging pieces 1: 1, 1, Hook 1; 3.5, the remaining accessories (main then, vice, support, screw, burst nails), etc. is 1. Wood keel ceiling ratio is: 3 * 4 wood side 1: 5.5 (including the use of boom), the rest is nails and other hardware. Gypsum board is basically 1: 1.1 (modeling should be open).

- Q: Light steel keel ceiling ,,, Commonly used is 50 to 50 system ,,, Light steel keel, the surface after the heat crossing zinc treatment, and long no rust, no deformation ,,, State regulations installed on the light steel keel on the gypsum board, as a class A fireproof material Wood keel because the water is too large, and love deformation ,,, no fire, so you can see Large place, no one is covered with wooden keel. The There are two real problems: 1 "with wood keel, the effect is not bad, and the cost is not cheap ,,, now light steel 50 keel and 3 * 5 wooden cost

- Light steel keel has the following advantages: light steel keel long unchanged. Light steel keel, the surface of high galvanized, long no rust, more could not be pest ants. Light steel keel is non-combustible material, no fire hazard Light steel keel environmental protection beyond wood material; light steel keel installation no noise, connected firmly, and to ensure environmental health; light steel keel is a new ceiling material, widely used in home and engineering The Wooden wood ceiling damage: the absorption of air in the air, especially in the northeastern weather, thermal expansion and contraction, inevitable deformation, leading to gypsum board cracking and deformation; wood material easy insects, ants and other organisms, harmful to humans. Wood material strength is not enough, it is easy to produce gypsum board subsidence, deformation and other issues; code nail connection easy to loose, shedding wounding; woody materials flammable, easy to cause fire; wood material keel applications will use fire retardant coating, Material in the installation, there is a strong "formaldehyde" gas volatilization; wood keel in the installation, must use nail gun, the noise is great, and woods flying, stimulate the body skin; wood ceiling, partition is already eliminated A structure, the project has been not allowed to use. From the construction cost and cost of considering the difference between the two little, light steel keel construction costs lower.

- Q: Light steel keel paper gypsum board ceiling construction process

- Material purchase requirements 1. Light steel skeleton sub-U-shaped skeleton and T-skeleton two, according to the load and not on the master. 2. Light steel skeleton main pieces for large, medium and small keel; accessories hanging pendant, connectors, hanging plug. 3. Spare parts: a boom. Flower blue screws. Nail. Self-tapping screws. 4. According to the design can choose a variety of cover panels. Aluminum pressure or plastic pressure every bar, the material varieties. Specifications. Quality should meet the design requirements. 5. Binder: should be selected according to the performance of the main material, before use for bonding test.

Send your message to us

Ceiling Profile Lamp Reflector Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords