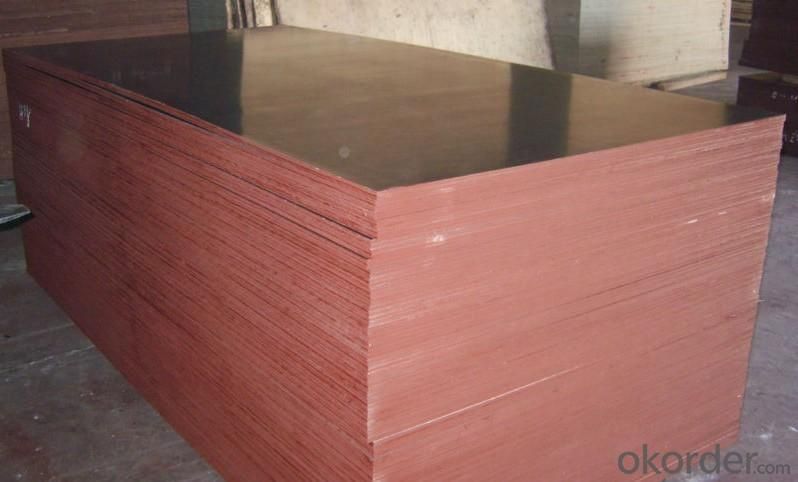

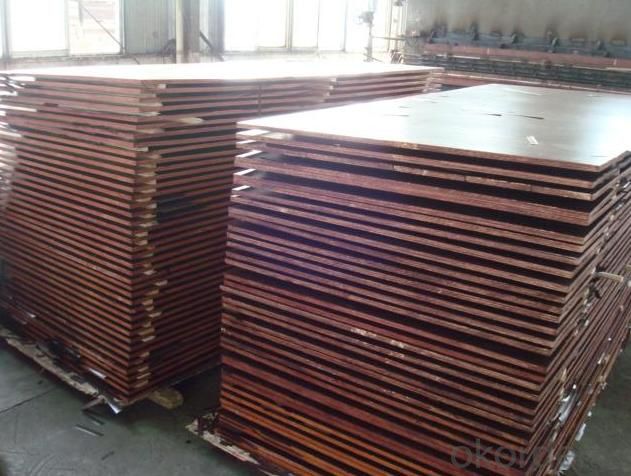

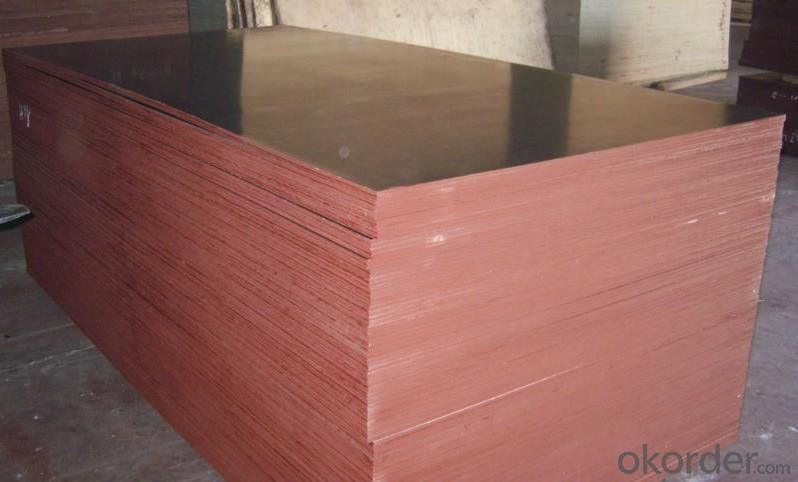

Cedar Plywood Poplar Core Brown Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Poplar Core Brown Film Faced Plywood are widely used in construction repeatly.

Characters:

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

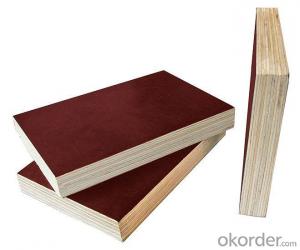

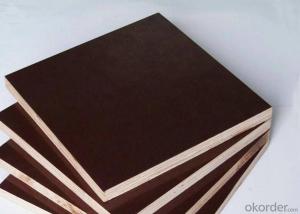

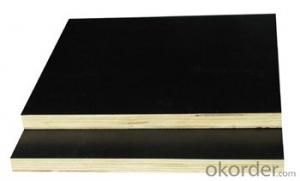

Product name: Poplar Core Brown Film Faced Plywood

Size:1220x2440mm,1250x2500mm

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar

Film:brown with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.How many times it can be used?

A1:For poplar core film faced plywood, it depends on glue type, eg. Melamine glue poplar core two times hot press, it can be used about 5-8times.

- Q: The structure of the plywood at the same time meet two basic principles

- the front panel is called the panel, the back of the table is called the back plate; the core

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: How do I determine if plywood contains formaldehyde?

- The plywood itself is easy to identify because each side can see the shavings that are pressed together, but it becomes hard to find it after making furniture

- Q: What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q: What is the difference between plywood glue E0E1?

- Urea-formaldehyde glue: moisture-proof glue / for interior decoration, furniture, can not be used for outdoor.

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Hard fiber board is also a density board

- Plywood boards can be full, and also allow splicing. The veneers of symmetrical layers on both sides of the center layer shall be of the same thickness,

- Q: Material for the plywood defects which

- false heartwood heartwood sound wood center part of the color is different from the normal wood, often dark brown or reddish-brown, usually its density and hardness are relatively large.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Plywood should be shipped with the factory quality inspection department of product quality certification, specify the type of plywood, specifications, grade, bonding strength and moisture content.

- Q: What are the types of veneer veneer veneer?

- Decorative veneer veneer plywood according to the decorative surface can be divided into single-sided veneer veneer plywood and double-sided veneer veneer plywood;

Send your message to us

Cedar Plywood Poplar Core Brown Film Faced Plywood for Construction

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords