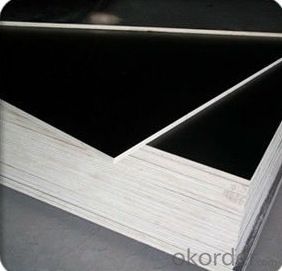

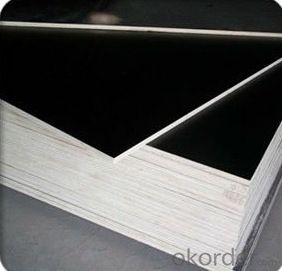

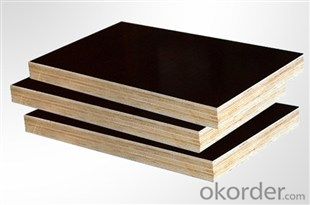

Treated Plywood Lowes Poplar Core Black Film Faced Plywood for Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

General Information of Poplar Core Black Film Faced Plywood

1.Size(mm): 1220x2440; 1250x2500 Thickness(mm):18; 15; 12; 20; 21

2.Glue: MR, melamine, phenolic, WBP Core: poplar, combi, hardwood, birch

3.Film: Dynea film or as requested Color: black

4.Application :Construction material used for concrete forming moudlings.

5.Standard ISO9001

Pictures:

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers' requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications of Poplar Core Black Film Faced Plywood

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main market:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

Advantage of Poplar Core Black Film Faced Plywood

1.No wrapping, no fracture,not out of shape , it can stay 24hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

4.Make the surface of concrete more smooth and beautiful,so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and ir will nor pollute the surface of concrete.

7.It is good to keep performance warm,ia favorable to make constrution in winter.

8.Products can be made into warping plywood

9.It is better to nail,saw,drill than bamboo and steel mould,can it can be processed into different type

FAQ: 1.What's color of the film faced plywood Edge?

Normally brown color, red color and black color.

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q: Judging wood is the standard for plywood

- Rare wood is only used to make very upscale furniture, and is often used in combination with lower-priced wood

- Q: How do you choose plywood in plywood production?

- but the overall furniture, wood is made of other wood, and now the store will be the furniture as "

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- on the requirements of the multi-layer solid wood flooring as strict, which is our daily common plywood or plywood bending reasons.

- Q: Further processing of the plywood

- plywood treated plywood plywood used in the manufacturing process or after manufacturing to deal with the physical properties of coupons.

- Q: What harm does the plywood factory work?

- occupational chronic benzene poisoning refers to the workers in the professional activities Long-term exposure to benzene vapor caused by hematopoietic system damage as the main manifestation of systemic disease.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Plywood: Plywood is a three or more plate-like material that is cut into veneer or cut into wood by wood and then glued with an adhesive

- Q: What is medium density fiberboard

- Plywood can be structured, gluing performance, surface processing, treatment methods, shape, use to classify, commonly used is an ordinary plywood

- Q: Poisoning diagnosis and grading standards

- and exclude other Caused by changes in blood, can be diagnosed as chronic benzene poisoning;

Send your message to us

Treated Plywood Lowes Poplar Core Black Film Faced Plywood for Construction Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords