Casting round head nut

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Model Number: | |||||

| Type: | Scaffolding Part Type: | Application: | |||

| Color: | Base plate: | Screw bar: | |||

| Weight: | Raw material: | Surface: | |||

| Adjustable length: | Welding: |

Packaging & Delivery

| Packaging Detail: | package:800 pieces steel jack for one stack with no external package. One stack of Scaffolding Jack Nut k is 3 CBM. |

| Delivery Detail: | 15-20 days after deposit |

Specifications

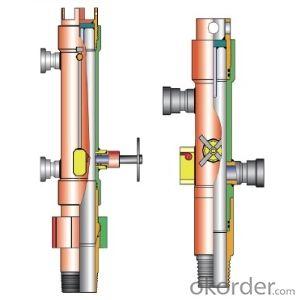

Scaffolding Jack Nut

1.made of seamless round steel

2.adjustable length

3.600*34mm u head jack

4.Solid shaft screw, casting

1. Steel Scaffolding Jack Nut is adjustabe scaffolding jack which can be adjusted within 20cm-40cm.

2. The surface of Scaffolding Jack Nut will be dip painted to resist rustiness and corrosion.

3. The connecting part is strong welded so that Scaffolding Jack Nut can bear high loading without damage.

4. The solid round steel have a high loading capacity so the solid shaft jack can support heavy concrete system without deformation.

Specification of Scaffolding Jack Nut

| Type | specification | weight |

| U head jack | 600*34,160*90*30*5mm | 4.8kg |

| 700*30,160*90*30*5mm | 4.5kg | |

| jack base | 600*34,120*120*5mm | 4.5kg |

| 700*30,120*120*5mm | 4.3kg |

we can provide different kinds of scaffolding steel jack for you.

- Q: I'm gonna be getting piercings this weekend, so i know im already getting my nose. but i want to get my ear. like barbell? so what's the difference between Scaffold and Industrial?

- They're the same thing. Different places call them different things.

- Q: New features of quick dismantling scaffolding?

- Preservative treatment: Advanced electrophoresis paint treatment, both inside and outside the paintCorrosion effect is longer than the traditional painting and painting steel tube life of 5-8 years

- Q: Im hoping to get an industrial/scaffold piercing done at the very beginning of the summer holidays.Is it possible that they can be pierced with 2 separate pieces of jewellery rather than one bar.Also would it be healed in time to take it out once the holidays are over (6 weeks)??Please help??!?Thanks x

- nope! Cartilage piercings take about a year to fully heal up. Yes, you can get 2 separate bars, but let the piercer know thats what you want. Industrials are VERY hard to take care of. Make sure to listen to EVERYTHING the piercer says!

- Q: Which kind of scaffolding is the most convenient and time-saving?

- The advantages of the new scaffold (compared with the bowl button) are as follows:1, with sufficient mechanical strength, stiffness and stability, safe and reliable work.2, the node connection without frame degree, has the ability to self lock, installation and disassembly flexible and quick, easy to grasp, support, removal efficiency than the bowl buckle type multifunctional scaffolding about three times, can save labor, labor, save time. In the process of construction, opening and closing channels at any time.

- Q: I couldn't believe it, but yes it happened...

- With God all things are possible.

- Q: How many time was Hester Prynne on the scaffold? why was she on it each time? What about the time when pearl and dimmesdale was on it with her? HELP!!!

- Hester Prynne On The Scaffold

- Q: Which loads are considered in the design of the scaffold

- The variable load of the scaffold shall contain the following contents:1) construction load: including the personnel, equipment and materials, etc.;2) wind load.Safety code for construction of steel tubular scaffold with couplers JGJ130-2011

- Q: How to calculate the vertical force of scaffolding

- The calculation of steel tubular scaffold with reference to "construction safety code for steel tubular scaffold with couplers" (JGJ130-2001). Need to calculate the following eight aspects:

- Q: Im a wimp for pain and im looking to get my scaffolding done. i want to know how painful it isI already have both lobs pierced and stretched to an 8mm, will the pain be similar to that?

- You sound like you have a low tolerance for pain if you say you're a wimp haha, which means yeah it'll probably hurt you. It'll hurt more than the lobes because it's cartilage, and for the same reason you'll hear a popping noise as the hole is made. You won't be taken over by deathly pain or anything like that, it'll probably be sensitive for a few days after too so careful not to knock it against anyone/ anything. But if you want it bad enough, the pain will be bearable.

- Q: Which accessories are included in a movable scaffold

- Mobile scaffolding is the main frame, cross frame, cross diagonal brace, foot board, adjustable base and other components. The cross rod is also called the diagonal pull rod, and is a cross connecting rod which is vertically connected with the two door frames. The part of both ends of the rod part is punched with a pin hole, and the locking pin on the vertical rod of the door and the frame is locked when assembling.

Send your message to us

Casting round head nut

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords