Casting ductile iron manhole covers for mining and industry OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

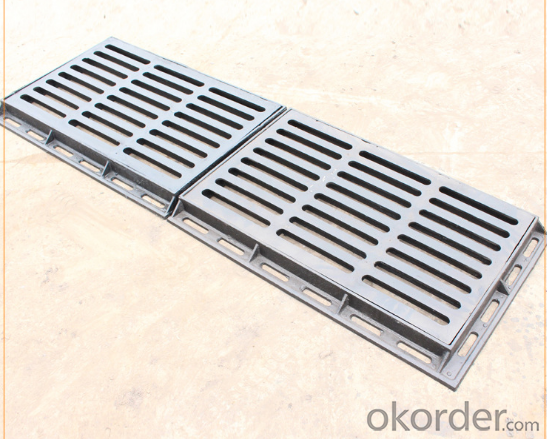

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

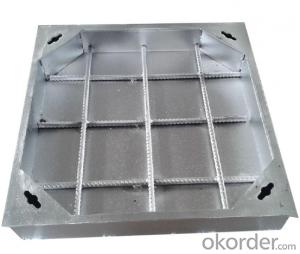

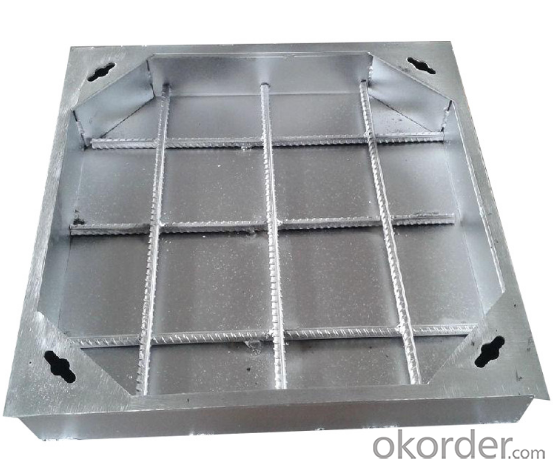

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 | 50 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 | 47 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. What is your minimum order requirement?

A: We will indicate the MOQ for each item in the quotation sheet. we accept the sample and trial order. If the quantity of single item can't reach the MOQ, the price should be sample price.

3. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- Use the vibrator to polish the material: the high aluminum porcelain 4cm (with a polishing agent that has an automatic mending function), you go find this polish,

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: What method of casting does not rust? I think the sample is like oil

- The surface of a general casting is easy to rust. In order to prolong the rusting period, antirust paint or antirust oil is usually sprayed. What you said should be anti rust oil.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- If it is not directly cast hole hole, later processing, large pores may be directly cast out,

- Q: How do you mark it on the drawing? Do you need to discuss it with the manufacturer?Because the casting allowance is the standard, then, after all, is the theoretical value, the actual level depends on the manufacturer, so is it necessary to ask the manufacturer?

- The general foundry casting technology division will mark put shrinkage and the allowance of the map in your chart (usually with the red pen) for the production of wood or other material wood workers die drawings.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q: How to solve casting defect casting?

- Prevention methodReduce the gas in the metal liquid and oxidize the slag, improve the fluidity of the metal liquidIncrease pouring temperature and pouring speed, strengthen slag collection, slag block or bottom pouring bag, teapot ladle pouring, can not cut off when pouring, prevent the slag from blocking the nozzle, and cause the casting to breakIncrease the sprue and sprue height, increase the runner section area and the sprue number, and improve the filling speed and the metal hydrostatic headImprove the casting design and increase the thickness of the thin-wall part of the castingChange the pouring position and pouring system, the casting thin wall plane is located at the top and away from the gate, to prevent the filling of liquid metal splashing, eddy current, avoid metal stream in the casting thin sections or core support, cold iron, insert the confluence, when necessary, take horizontal vertical pouring cold or inclined castingIncrease the permeability of core and sand, strengthen the exhaust of mould, and the quantity of air outlet and riser should be enoughChange the size and location of the core, the inner cold iron, the core support, the internal cold iron, the insert should be no rust, no oil pollutionCheck the type, tight box, press the operation of iron is safe, to prevent running fire

Send your message to us

Casting ductile iron manhole covers for mining and industry OEM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches