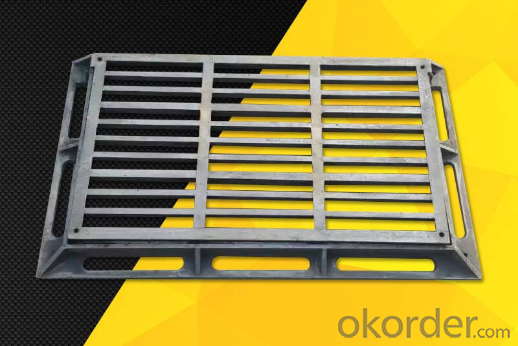

Casting Ductile Iron Manhole Covers C250 for Mining with Competitive Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type:round type and Square type,triangle

4) Sand casting

5).we can produce as per customers'drawings

6)ISO9001:2008

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| SC42 | C250 | 330*330 | 420*420 | 50 | 20 |

| RGC-01L | C250 | 390*325 | 530*465 | 100 | 23 |

Advantages

Good compressive, bending and impact strength, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I get free samples?

A: Yes, we can provide you the free sample, but you need to bear their own delivery costs.

2.Can I request to change the form of packaging and transportation?

A:Yes,We can change the form of the packaging and transportation according to your request, but you have to bear their own costs incurred during this period and the spreads.

3.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

4.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: How is the silicon sol precision casting part priced? What is the price per ton of casting? Such as 304 material.

- The material is usually steel material price plus the cost (per ton of 2.5-3 million, plus profit).In the Yangtze River Delta region, generally 304 casting price of about 5-5.5 million / ton.The price will be higher if the parts are complex, or a piece weighs less than 100 grams.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- Good welding of low carbon steel (alloy), probably because the weld workpiece rigidity, fast cooling, the weld internal crystallization of brittle microstructure (martensite), so after welding or welding process welding using self heat, reasonable arrangement of weld, welding seam and heat affected zone heat treatment. The welding heat treatment is often used to preheat before welding, after welding withasbestos cloth covering slow cooling annealing, reach the purpose, its main function is to reduce the internal stress, improve the weld microstructure of martensite formation, reduce brittle tendency, preventing welding cracks.

- Q: In theory, which is more expensive, forging parts or casting parts?

- Compared with the price, the product with the same simple structure eliminates the material factorsThe forgings must be more expensive

- Q: What are the casting parts processing engineering?

- According to the classification of process methods, sand casting and special casting.

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- 304 stainless steel is easier to change than ordinary steel. Because the 304 heat conductivity is lower than that of the low doped steel, the temperature is even more uneven, and 20% of the non ferrous elements also make the distribution of internal and external elements more uneven, hard and soft inside. Each of these two produces greater internal stresses, resulting in a variant.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: Does anyone know how to make precise casting parts for aerospace or manufacturers of single and small quantities of automotive parts and components, mainly in Beijing, Tianjin and Tangshan?

- List of China's military enterprises list of ten major military groupsChina Nuclear Industry Construction Group CorporationChina Aerospace Science and Technology CorporationChina Aerospace Science and Engineering CorporationChina Aviation Industry CorporationChina Aviation Industry Corporation IiChina State Shipbuilding CorporationcsicChina North Industries Group CorporationChina South Industries Group CorporationChina National Nuclear CorporationKey military enterprisesShipbuilding industry:China State Shipbuilding Corporation (South ship group), (China Shipping Group)China Shipbuilding Industry Corp (North Ship group), (China Shipbuilding Industry)Guangzhou Shipyard International Limited by Share Ltd (GSI)Jiangnan Heavy Industry Limited by Share Ltd (Jiangnan Heavy Industry)Nuclear industry:China National Nuclear Corporation (CNNC)China Nuclear Industry Construction Group Corporation

- Q: How to cast iron and wrought iron collocation

- 2, listen: Pig beating sound boring, wrought iron beating sound loud.

Send your message to us

Casting Ductile Iron Manhole Covers C250 for Mining with Competitive Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches