Cast Iron / Ductile Iron Strainer Flange end with China Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Strainer Description:

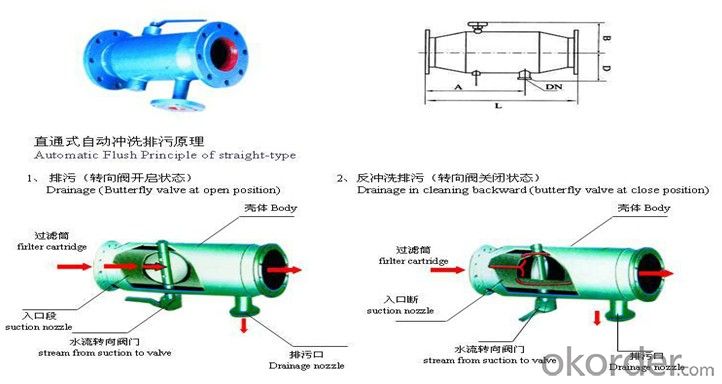

Filter by cylinder, stainless steel mesh, sewage part, transmission device and electric control parts. Filters work, to filter into the water from the nozzle, flows through the filter, and through the export pipeline into the user required to process cycle, the particles in the water acrobatic trapped inside the filter. So continuously circulation, more and more particles trapped down, filtration speed slower and slower, and imports of sewage is still continue to enter, filter hole will be more and more small, thus produce pressure difference between inlet and outlet, when poor magnanimous to set data, differential pressure transmitter will be routed to the controller, control system startup drive motor through the mechanical drive shaft rotation, open the outlet at the same time, by the discharge outlet, when the screen is clean, differential pressure drop to the minimum, the system returns to the initial filter, normal operation of system. Filter by shell, multiple filter, backwash, and differential pressure controller and other components. Casing of diaphragm plate inside cavity can be divided into upper and lower two cavity, the cavity is equipped with multiple filter core, so the filter space fully, significantly reduces the volume of the filter, are installed in the inferior vena recoil wash suction cups. Work, fluid after the entry into the inferior vena filters, and filter the inner cavity of the baffle hole. Is greater than the filtering core crack impurities trapped, net fluid cavity through the gap to, finally from exports. Wedge mesh filter with high strength, through differential pressure control, timing control automatic cleaning filter. When caused by impurities accumulate in the filter surface inside the filter differential pressure increases to the set value of imports and exports, or the timer reaches the preset time, electric control box signal, drive back flush. When backwash suction dish and filter imports are pair, the drain valve is opened, the system pressure drainage, chuck and filter the inside a relative pressure below the filter of the lateral pressure of negative pressure zone, forcing some net circulating water from the inside filter lateral flow filter, adsorption on the inner wall of the filter in the impurity particles with flow into disc and is discharged from the drain valve.A specially designed mesh filter internal injection effect, any impurities will be washed away from the smooth wall.When the filter differential pressure returned to normal import and export or timer setting time end, the whole process, and the material does not block the backwashing water consumption less, to realize the continuous, automatic production.Filter is widely used in metallurgy, chemical industry, petroleum, paper making, medicine, food, mining, power, urban water supply area.Such as industrial waste water, circulating water filtration, emulsion of regeneration, the waste oil filter processing, metallurgical continuous casting of water system, water system, blast furnace hot rolling with high pressure water descaling system.Is an advanced, efficient and easy to operate automatic filter is installed.

2. Main Features of the Strainer:

• Efficient, accurate filtering: the special structure of the filter disc filter technology, precise sensitive, make sure that only size is less than the requirements of the particles can enter the system, is the most effective filtration system;Specifications are 5 mu, 10 mu, 20 mu, 55 mu, 100 mu, 130 mu, 200 mu, the user can select different precision filter plate according to the water requirement. System flow can be adjusted according to the need to be flexible.

• Standard modular, save floor: system based on the standard disc filter units, according to the modular design, the user can demand trade-offs, flexible, strong interchangeability. System is compact, covers an area of small, flexible use of edge space for installation, such as water treatment equipment covers an area of about 300 m3 / h only about 6 m2 (general water quality, filter level 100 mu).

• Fully automatic operation, continuous water: in the filter combination between each unit, take turns to alternately backwashing process, work, backwashing automatically switch between state, to ensure continuous water;Backwashing water rarely, only 0.5% of the water yield;Such as auxiliary backwashing with air, the water consumption to be below 0.2%.Rapid and thorough backwashing, only tens of seconds to complete

• Long life: new plastic filter elements, no wear, no corrosion, little scale, the industry for many years practical validation, using 6 ~ 10 years did not wear, not aging, filtration and backwashing effect will not change by using time difference.

•High quality, less maintenance, products comply with relevant quality standards, all products before they go out by simulating condition testing and commissioning, does not need special tools, spare parts less;Easy to use, only need regular check, almost daily maintenance is not required.

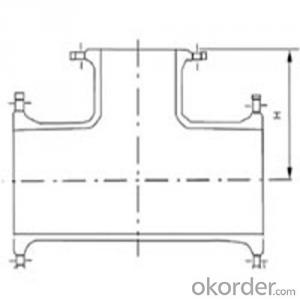

3. Images

4. Strainer Specification

5.FAQ

1. What's are the characteristics of Strainer ?

The distinct feature of a strainer is the sealing surfaces between the gate and seats are planar, so strainers are often used when a straight-line flow of fluid and minimum restriction is desired. The strainer faces can form a wedge shape or they can be parallel.

2. What is the work principle of strainer?

The strainer faces can form a wedge shape or they can be parallel. Strainers are primarily used to permit or prevent the flow of liquids, but typical strainers shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, strainer s are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. strainers may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: Where is the hydrant main valve?

- The intake valve of the upper and lower ring pipes of the riser of the fire hydrant is generally located at the highest and lowest floors.The general use of the valve rod flange gate valve.Hydrants, officially called fire hydrants, are a type of fixed fire fighting facilities, which control fuel, insulate fire and eliminate fire. Indoor fire hydrant and outdoor hydrant. The fire fighting system includes outdoor fire hydrant system, indoor fire hydrant system, fire extinguisher system, and some automatic sprinkler system, water gun system, gas fire extinguishing system, fire detection system, water mist system and so on. Fire hydrant mainly for fire engines from the municipal water supply network or outdoor fire water network to implement fire fighting, can also be directly connected to the hose, water gun fire extinguishing. Therefore, indoor and outdoor fire hydrant system is also one of the important fire fighting facilities.

- Q: How to identify the good or bad of the valve, without pressure test and instrument?

- First, the appearance, two according to the standard to see flange thickness, outer circle, wall thickness and other dimensions are standard, 3 see details.

- Q: Valve category can fill the trunk door, branch valve Mody?

- Valve category can fill the trunk door, branch valve? "no, too general."

- Q: HH valve company in the United Kingdom, how about the valve?

- Our factory boiler has this brand of valve, used for many years, has been no problem, really good.

- Q: How do I open the gas valve?

- First of all, you have to determine the direction of the valve opening, usually homeopathy, it is off, the reverse is open. First: to determine the opening of the valve, are generally ball valve, screw 90 degrees on it. Second. At the top of your house, there is a button that can be pulled out. It's different from place to place. Some are pulled out half, and some are pulled out.

- Q: Which direction is the valve? Which direction is it?

- Generally: clockwise, counterclockwise, looseYou can also see the logo on the spool

- Q: What items and detailed procedures should be inspected for valve size inspection?

- Valve body structure length and flange size, GB size, the implementation of GB/T12221-2005. American Standard. (the American Society of mechanical engineers ASME B 16.10-2000).

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: What's the valve as a unit?

- Business now there are many valve manufacturers, with the rapid expansion of SMEs, SMEs are more ~!

- Q: Why can't the clip type check valve be directly connected with the pipe mouth or other valves?

- The clip type check valve is made up of two discs to prevent backflow.If the clip check valve is connected to the other valve, the disc may touch the valve and cause the check valve not to be fully opened or closed. This is a preliminary analysis of "enter the valve", for reference only!

Send your message to us

Cast Iron / Ductile Iron Strainer Flange end with China Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords