Casing antichafe machine pipe wear in the drill pipe joints

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction:

The loss of the drive pipe wear in the drill pipe joints can’t be ignored during the processing of the deep mine, ultra-deep well, horizontal well and directional well. Using casing abrasion can effectively reduce the wear of drill pipe joints and lower the friction torque during the time of the drill pipe rotate. The both ends of the casing abrasion is conventional drill buckle, it can be easily individual or assembly used according to the requirement of well drilling.

2.Casing antichafe machine characteristics

.Adopting cemented carbide bearing, drilling fluid lubrication, long life, low friction coefficient.

.Made by high strength alloy steels, high strength, safe and reliable.

.Outside sliding sleeve is used low hardness alloy and antifriction composite.

3.The basic size of antichafe machine

Type

| The whole length mm | OD

| Nozzle

| Both ends screw

| Lubrication method

| Strength rank

|

Ф146 | 760 | 148 | 68 | NC38 | drilling fluid

| The same as the intensity of the drill pipe joints

|

Ф197 | 840 | 197 | 75 | NC50 | drilling fluid

| |

Ф203 | 840 | 203 | 75 | 5½"FH | drilling fluid

| |

Ф206 | 840 | 206 | 75 | NC50 | drilling fluid

| |

Ф240 | 840 | 240 | 85 | 5½"FH | drilling fluid

| |

Ф260 | 915 | 260 | 85 | 5½"FH | drilling fluid

|

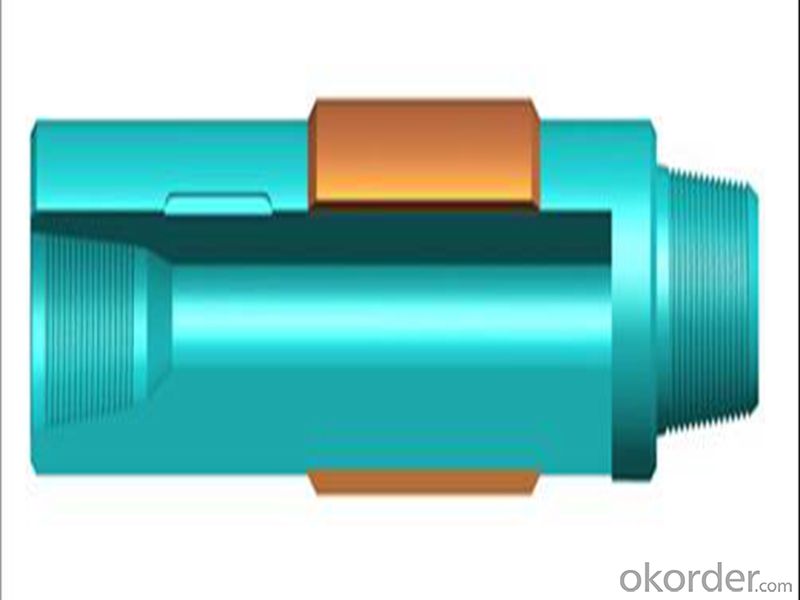

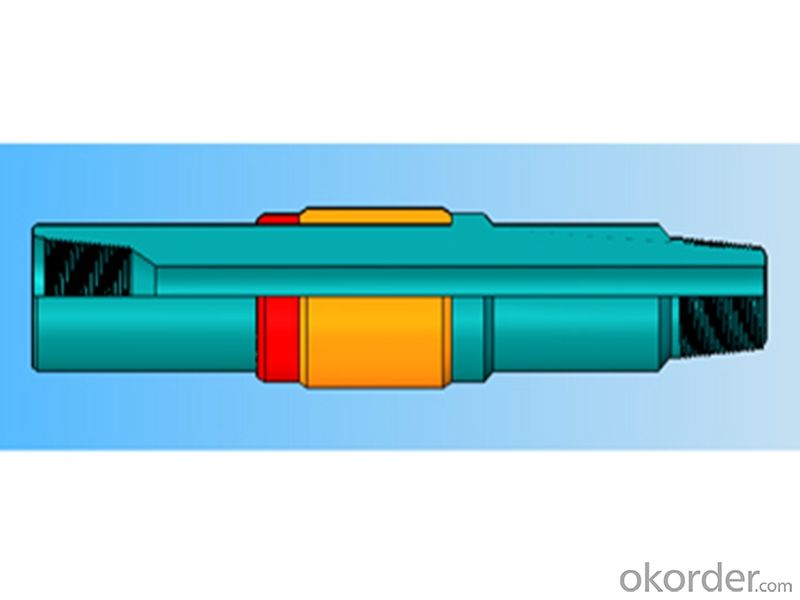

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: A bearing assembly that can withstand greater torque (other requirements are not required and the axle is cantilevered)

- Suggest landlord or two sets of bearings is better, and two bearings away from the point of good. That is to say, the closer the couplings are from the motor.

- Q: Isn't it the middle question or the other question? I'm looking for glfore to do the test. Did anyone do that?

- Possible in the middle. There may be other problems. You can try with them. Excellent

- Q: What are the five types of bearings? Like F~G...? What else? Who knows?

- 6 categories: angular contact ball bearings, four point contact ball bearingsThe 7 category: tapered roller bearingsThe 8 Category: thrust ball bearings9 category: thrust roller bearingsPure hand-made, adopt landlord

- Q: Can I use other types of bearings instead? What's the model instead of the bearing? Thank you

- Hello, please check the model of this bearing in detailThere is no PN307 modelWith RN307, cylindrical roller bearings, bore 35Then consult me

- Q: How can I solve this problem? FifteenOur motor is used in the submersible pump, the speed in the 3000 turn around /min, now excessive vibration occurs, or for a better quality of the bearing vibration is too large, please professional prawns, this is what reason? How to solve?

- It is estimated that the bearing clearance is too large to cause vibration. If the original pump work environment temperature of 20 degrees, now 5 degrees. When the thermal expansion of the bearing decreases and the clearance becomes larger, the vibration of the motor will be too large. It is suggested that the clearance bearings be selected according to the running temperature and speed of the motor.

- Q: 1.6 of the two case K2 rear wheel bearings are the same as the other K2?

- if we can determine the type and the brand can determine the price, in addition to bearing high precision machinery products, try not to buy Taobao, best buy through formal channels....

- Q: What about the other workshops? Yes, I have a share in it. Which workshop is better in Changzhou?,

- Not how, in charge of the following people will always be with you to see Japanese kneeling lick. The pay is low and prudent

- Q: Characteristics of cross roller bearings

- Cross roller bearings, with the inner and outer ring divided into, roller and interval retainer, and cross roller collar fixed together, separated from each other to prevent the installation of cross roller collar simple operation. Because roller cross arrangement, so only 1 sets of cross roller collar can withstand various direction load, compared with the traditional model, increase the rigidity of 3~4 times. At the same time, because the cross roller bearing inner ring or outer ring is a two division structure, the bearing clearance can be adjusted, even if the preload is applied, high precision rotary movement can be achieved.1, with excellent rotation accuracyThe internal structure of cross roller bearings is made of 90 degrees vertical cross arrangement of rollers,The roller is provided with an interval retainer or an isolating block, which prevents the tilting of the roller and the grinding between the rollers. In addition, the phenomenon of side contact or locking of the roller can not occur; at the same time, because the inner and outer ring is a segmented structure, the clearance can be adjusted, and even high-precision rotation can be obtained even if the preload is applied.2. Simplify the operation and installationThe outer ring or inner ring divided into 2 parts is fixed together after the roller and retainer are mounted, so the installation is very simple.3, bear larger axial and radial loadBecause the rollers are arranged perpendicularly to each other on the rolling surface of the V groove on a 90 degree angle.

- Q: What are the world bearing giants?

- Domestic comparison of large-scale bearing companies, mainly in the following:HRB (Kazakhstan axis) LYC (Luozhou) ZWZ (Wa Zhou) axis Institute of Technology (ZYS)Northwest axis universal bearings, human bearings, Tianma bearings, Xiangyang bearings, Jinxi axle, Longxi bearings, and so onAt present, about eight or nine listed Bearing Enterprises

- Q: I feel different from other factories, ah, there is no pungent smell!

- You go to Harbin axis Ji'nan company to ask, they are the factory's direct center, can solve your problem

Send your message to us

Casing antichafe machine pipe wear in the drill pipe joints

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords