X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Xover sub acts for conversion and connection of drill stem component in petroleum, natural gas and geology drilling work. It is one of the main tools in connect the upper tool and the bottom Hole. It is used mainly for connecting of upper drill tools and lower drill tools during drilling operations when upper and lower buckle type failed to connect during drilling operation.

2.Features:

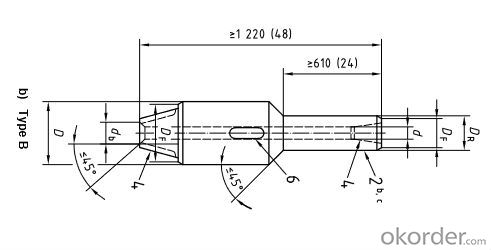

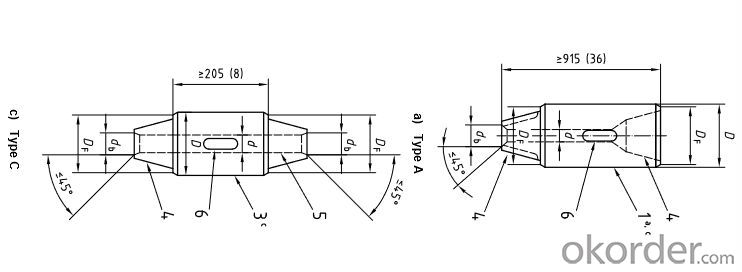

3. The basic structure of the X-over sub

Variety | name

| Upper link

| Lower link

| Type

|

1 |

| Kelly

| Drill pipe joints

| A or B A或B |

2 | drill pipe Cross-over sub

| Drill pipe joints

| Drill pipe joints

| A or B A或B |

3 | Transition Cross-over sub | Drill pipe joints

| drill collar

| A or B A或B |

4 | drill collar Cross-over sub

| drill collar

| drill collar

| A or B A或B |

5 | Borehole Cross-over sub

| drill collar

| drill collar

| A or B A或B |

6 | Faucet Cross-over sub

| Faucet

| Kelly bar

| C A或B |

7 | Salvaging Cross-over sub

| Kelly

|

| C

|

Drill pipe joints

| Fishing Tools

| C |

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can I use other types of bearings instead? What's the model instead of the bearing? Thank you

- Hello, please check the model of this bearing in detailThere is no PN307 modelWith RN307, cylindrical roller bearings, bore 35Then consult me

- Q: It is a special household pump, round about half a meter longOpen when the leakage coil, and the three set of bearings replaced, can not use it, has been tripped, how the more repair the worse? Is it true that the repair shop is intentional?

- Hello, according to your description:Water pump bearings only a bad disk, then only need to replace a plate of bearings, the other two plates do not need to replaceI hope my answer can help you, what questions please continue to ask questions, thank you for your adoption!

- Q: In bearings, why are the flanges connecting the upper and lower cases higher than those of the other bearings?

- If it is understood as the reducer, the upper and lower box connecting the flange (bearing box outside the prominent part), the reason is to prevent the bearings in operation, gear and box friction, damage box, reduce gear life.

- Q: Yoyo how can I wash the bearings without gas?. What other materials can I use?

- Thinner, acetone, chloroform, banana water, kerosene.

- Q: What about the other workshops? Yes, I have a share in it. Which workshop is better in Changzhou?,

- Not how, in charge of the following people will always be with you to see Japanese kneeling lick. The pay is low and prudent

- Q: The car separation bearing is broken, isn't it? What's the cause of the other broken bearings?

- Judging the quality of the separation of bearings: step down the clutch pedal to half linkage position, and then make a noise, you can judge the separation of bearing damage

- Q: SKF bearing samples provide full set of SKF bearing samples, and other brand samples

- Bearing samples directly to the company, want it to send ah ~ we are all so ~ even if I have, how to give you?

- Q: In addition to NSK and KOYO, what are the other four major bearing producers in Japan?

- NSK in Japan bearing is the largest share of the domestic market after the Swedish SKF, NTN and Koyo other than NSK.

- Q: What are the world bearing giants?

- International bearing giants:Sweden: SKF (SKF group)Germany: INA/FAG (Schaeffler group)United States: TIMKEN (The Timken Company)Japan: NSK (Nske) NTN (NTN) KOYO (Guang Yang) NACHI (fujikoshi)NMB (Mei Beiya) THK (main line, unit FYH (bearing) main bearings etc.).The Swedish SKF company was founded in 1907, in the rolling bearing sector is the world's leading supplier, experience and professional skills of the bearing and bearing unit, seal, lubrication system, electromechanical integration and service five platform with its more than 100 years, SKF has become a knowledge-based company. In 2007, SKF sold more than SEK 58 billion 500 million.The German Schaeffler Group owns three brands: INA, FAG and LuK, are rolling bearings and linear motion products leading manufacturer, supplier of automotive industry is also well-known engine, gearbox, chassis applications of high precision products and systems. The group represents a high degree of customer focus, exceptional innovation, and highest quality standards. The group has about 74000 employees worldwide, with more than 180 branches in more than 50 countries, with sales of about 10 billion 700 million euros in 2011. This makes the Schaeffler group one of the largest family business groups in Germany and europe.The Timken Company was founded in 1922, operating range: aviation, construction, medical, heavy industry, machine tools, consumer goods, energy and industrial equipment. Wuxi solid Chinese sales agent TIMKENTIMKEN bearing inner ring bearings Co. Ltd., TIMKEN bearing outer ring, roller bearing TIMKEN, TIMKEN bearings, TIMKEN bearings accessories, TIMKEN bearing, TIMKEN metric 3000 series. The The Timken Company set up eight technical centers

- Q: Why are the front fork bearings of the GY6 so difficult to buy, smaller than others?

- GY6 pedal motorcycle, in addition to the crankshaft on the right side of the starting driven gear, there is a reverse Taiwan screws, other screws include the front fork, each screw is thread.

Send your message to us

X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords