Carton Seamless standard pipe ASTM A53/API 5L

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Carton Seamless standard pipe ASTM A53:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of Carton Seamless standard pipe ASTM A53:

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

• High manufacturing accuracy

• High strength

3、Carton Seamless standard pipe ASTM A53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Carton Seamless standard pipe ASTM A53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

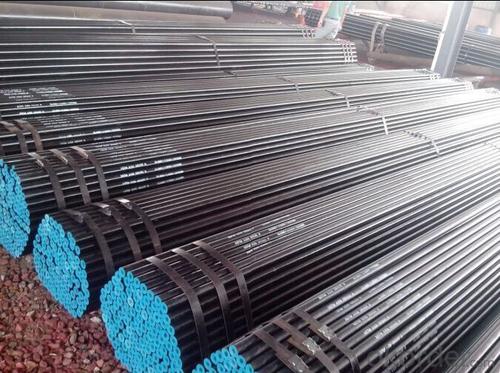

6、Carton Seamless standard pipe ASTM A53 Images:

- Q: What are the common methods of joining steel pipes?

- The common methods of joining steel pipes include welding, threading, and using mechanical couplings. Welding involves fusing the pipes together using heat, while threading involves screwing the pipes together using threads on the ends. Mechanical couplings are devices that connect the pipes together using compression or other means.

- Q: How do you repair damaged steel pipes?

- To repair damaged steel pipes, the first step is to assess the extent of the damage. If it's a small crack or hole, it can be fixed using a steel-filled epoxy or a pipe repair clamp. However, for more significant damage, such as extensive corrosion or a large rupture, cutting out the damaged section and replacing it with a new pipe is usually necessary. In some cases, professional welding or soldering may be required to ensure a secure and leak-proof repair.

- Q: What are the different types of steel pipe caps?

- There are several different types of steel pipe caps, each designed for specific purposes and applications. Some common types include: 1. Threaded Caps: These caps have internal threads that allow them to be screwed onto the end of a threaded pipe, providing a secure seal. They are commonly used in plumbing and gas applications. 2. Socket Weld Caps: These caps are designed to be welded onto the end of a pipe using a socket weld connection. They provide a strong and permanent seal, making them suitable for high-pressure and high-temperature applications. 3. Butt Weld Caps: Similar to socket weld caps, butt weld caps are also used for welding onto the end of a pipe. However, they are specifically designed for butt welding, which involves welding the cap directly to the pipe without any additional fittings. 4. Domed Caps: These caps have a domed or rounded shape on the upper surface, providing a smooth and aesthetically pleasing finish. They are commonly used in architectural and decorative applications, such as handrails or fence posts. 5. Flat Caps: As the name suggests, flat caps have a flat surface on the upper side. They are often used when a simple and low-profile cap is required, such as for protecting the ends of pipes in industrial applications. 6. Blind Caps: Blind caps are used to seal off the end of a pipe permanently. They are solid caps without any openings or threads, ensuring a complete closure. They are commonly used in piping systems where a section of the pipeline is not in use or needs to be closed off temporarily. These are just a few examples of the different types of steel pipe caps available. The choice of cap depends on the specific requirements of the application, such as the type of connection, pressure, temperature, and the need for structural or decorative finishes. It is important to select the appropriate cap to ensure a secure and reliable seal for the pipe.

- Q: How are steel pipes coated to prevent corrosion?

- To prevent corrosion, steel pipes can be coated using different methods and materials. One common approach is to apply a protective layer of paint or epoxy on the pipe's surface. This coating acts as a barrier between the steel and the external environment, preventing direct contact with moisture and corrosive substances. Another technique involves galvanization, where the steel pipes are coated with a layer of zinc. Zinc is highly resistant to corrosion and acts as a sacrificial anode. In case of any damage to the coating, the zinc corrodes instead of the steel, ensuring the steel remains intact and free from corrosion. Polyethylene or polypropylene materials can also be fused onto the steel surface, creating a strong bond that provides excellent resistance against corrosion. This method, known as fusion bonding, is commonly used in offshore and underground pipelines. Moreover, a layer of corrosion-resistant alloy can be applied to the steel pipe. This alloy is typically a combination of metals such as nickel, chromium, and molybdenum, which offer superior protection against corrosion in harsh environments. The choice of coating method depends on factors like operating conditions, the presence of corrosive substances, and the expected lifespan of the steel pipes. By effectively applying these coatings, steel pipes can be safeguarded against corrosion, extending their durability and ensuring the integrity of the infrastructure they are used in.

- Q: Can steel pipes be used for food processing facilities?

- Yes, steel pipes can be used for food processing facilities. Steel pipes are commonly used in food processing facilities due to their durability, strength, and resistance to corrosion. They are also easy to clean, which is essential in maintaining proper hygiene standards in food processing environments. Additionally, steel pipes can withstand high temperatures and pressure, making them suitable for various food processing applications such as conveying liquids, gases, and solids. However, it is important to ensure that the steel pipes used in food processing facilities are made from materials that are approved for contact with food, and that they are regularly inspected and maintained to prevent any contamination risks.

- Q: Which is better, galvanized steel pipe or stainless steel?

- In rural and urban areas, it is often necessary to wash them in order to keep them in the open. In the heavily polluted industrial and coastal areas, the surface can be very dirty and even rust. But to obtain the aesthetic effect of outdoor environment, it is necessary to use nickel stainless steel. Therefore, 304 stainless steel is widely used in curtain walls, side walls, roofs and other building applications, but in corrosive industrial or marine atmospheres, it is better to use 316 stainless steel. There are several design criteria including 304 and 316 stainless steel.

- Q: Can steel pipes be used for hydroelectric power plants?

- Yes, steel pipes can be used for hydroelectric power plants. Steel pipes are commonly used to transport water in hydroelectric power plants for various purposes such as intake systems, penstocks, and discharge systems. They offer durability, strength, and resistance to corrosion, making them suitable for the challenging environments found in hydroelectric power generation.

- Q: How do you calculate the weight of steel pipes?

- To calculate the weight of steel pipes, you would need to know the dimensions of the pipe, including its outer diameter, inner diameter, and length. By using the formula for the volume of a cylinder, which is πr²h, where r is the radius (half the diameter) and h is the height or length of the pipe, you can calculate the volume of the pipe. Then, by multiplying the volume by the density of steel, which is typically around 7850 kg/m³, you can determine the weight of the steel pipe.

- Q: What are the different types of steel pipe coatings for offshore applications?

- There are several types of steel pipe coatings commonly used for offshore applications. These include fusion-bonded epoxy (FBE) coatings, three-layer polyethylene (3LPE) coatings, three-layer polypropylene (3LPP) coatings, and concrete weight coatings. Each of these coatings offer different levels of protection against corrosion and abrasion in offshore environments, and the choice of coating depends on factors such as the specific offshore application, the surrounding environment, and the durability requirements.

- Q: Are galvanized steel tubes the same as degaussing steel tubes?

- Degaussing steel tubeThe degaussing method specifies the following demagnetization in the established process document

Send your message to us

Carton Seamless standard pipe ASTM A53/API 5L

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords