Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

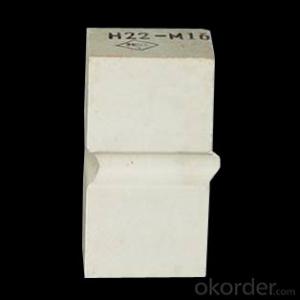

Silicon mortar is adhesive material matched with silica brick. Our silicon mortar has such advantages as high adhesive strength, high refractoriness, excellent refractoriness under load, and good installation performance.

Feature

Control the liquid system, Adhesive, Polymer's rheology and thixotropy.

As additive agent used to prevent subside,thickening and prevent sagging.

Reinforce HRC high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber.

Improve the quality of the powder, and improve the liquidity and anti-blocking characteristic.

Application

paint and coating, Unsaturated polyester resins, laminating resins and gel coat.

HCR high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber. Adhesive and fluid sealant, Printing ink, Cable rubber,Plant protection,Food and cosmetics.

Technical Data

| ITEMS | XR-150 | XR-200 |

Form | White powder | White powder |

Whiteness | 98 | 98 |

SiO2 (dry basis) % | ≥99.9 | ≥99.9 |

PH value | 3.5-4.5 | 3.5-4.5 |

BET surface area m2/g | 150±15 | 200±25 |

Bulk density g/L | 40-50 | 40-50 |

Average particle size nm | 14-15 | 14-15 |

Heating loss (105 for 2hr.) % | 0.5-1.0 | 0.5-1.0 |

Ignition loss (1000 for 2hr.) % | 1.0-2.0 | 1.0-2.0 |

package | 10kg/bag | 10kg/bag |

Photos for Workshop

- Q: Physical solid waste disposal

- Too much addition will reduce the refractory and mechanical strength, increase porosity, so the amount of waste brick should not be too much.

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: The introduction of silica brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: How much is the highest melting point of silicon?

- Acidic silica brick refractories, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. More than 94% silica content.

- Q: What are the main constituents of refractory bricks?

- Refractory brick composition is mainly composed of a variety of aggregate or aggregate and one or more kinds of sticky agent composed of mixed powder particles, when used, must be mixed with one or more liquids, mixing evenly, with strong liquidity. Different refractory bricks are different, such as silicon, aluminum, clay and so on:

- Q: Brick

- An acid refractory consisting mainly of quartz and square quartz and a small amount of residual quartz and glass.More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. When heating up to 1450 degrees, the total volume of 1.5~2.2% expands, and the residual expansion can close the kerf and ensure the airtight and structural strength of the masonry.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords