Calcined Petroleum Coke Originated in China Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 50kg/bag 100kg/bag 1000kg/bag Or according with client need to do |

| Delivery Detail: | 2 weeks |

Specifications

Calcined Petroleum Coke Originated in China Best Price

Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds.

Calcined Petroleum Coke

F.C.: 98.5%MIN

ASH: 0.8% MAX

V.M.: 0.7%MAX

S:0.5%MAX

Moisture: 0.5%MAX

Structure

Calcined Petroleum Coke Originated in China Best Price

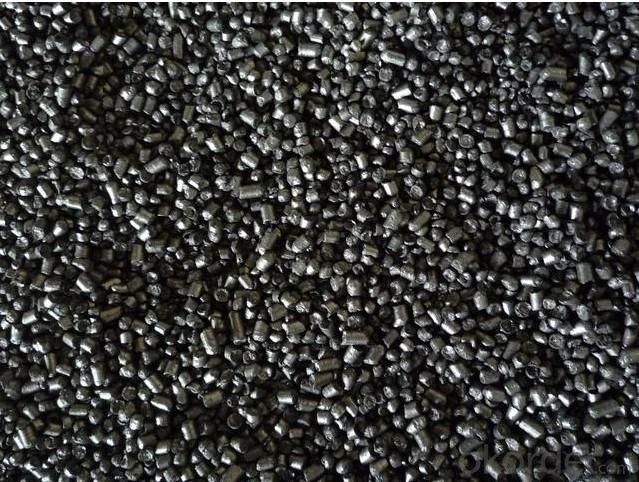

Shape: granule

Dimensions: 0-1mm, 1-5mm, 1-6mm, 2-8mm, etc

Product Type: Carbon Additive

C Content (%): 98-99.5% MIN

Working Temperature: -

S Content (%): 0.5%-0.7%MAX

Ash Content (%): 0.7%MAX

Volatile:0.8%MAX

Moisture: 0.5% MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

Feature

Calcined Petroleum Coke Originated in China Best Price

Physics and chemistry performance :

Unit | Index | |||||

No.1 | No.2 | No.3 | ||||

Density | g/cm3 | 2.04 | 2.00 | 2.00 | ||

sulphur content | %≤ | 0.5 | 1.0 | 2.5 | ||

volatility | %≤ | 0.5 | 0.5 | 0.5 | ||

ash content | %≤ | 0.5 | 0.5 | 0.5 | ||

moisture | %≤ | 0.3 | 0.5 | 0.5 | ||

charcoal | %≤ | 98.5 | 98.0 | 98.0 | ||

Image

Calcined Petroleum Coke Originated in China Best Price

FAQ:

Calcined Petroleum Coke Originated in China Best Price

How to classify calcined petroleum coke?

1) According to difference of sulfur content, can be divided into high sulfur coke (sulfur content more than 4%), sulphur in coke sulfur content (2% 4%) and low sulfur coke (sulfur content below 2%).

2) Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds:

3) Needle coke, has obvious needle-like structure and fiber texture, mainly used for steel-making in high power and ultra-high power graphite electrode. As a result of needle coke in sulfur content, ash content, volatile matter and true density and so on have strict quality requirements, so the production process of needle coke and raw materials have special requirements.

4) The sponge coke, high chemical reactivity, low content of impurities, mainly used in the aluminum industry and carbon industry.

5) Focal or spherical coke: the projectile shape is round, diameter 0.6-30 mm, usually from the production of high sulphur, high asphaltic residual oil, can only be used as industrial fuel power generation, cement etc.

6) Coke breeze: fluidized coking process, the fine particles (0.1- 0.4 mm) in diameter, high volatile, high expansion coefficient, cannot be directly used for electrode preparation and carbon industry.

Advantage:

Calcined Petroleum Coke Originated in China Best Price

1. High quality and competitive price.

2. Timely delivery.

3. If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: What are the effects of carbon emissions on the stability of ice shelves?

- Carbon emissions have significant effects on the stability of ice shelves. As carbon dioxide (CO2) and other greenhouse gases are released into the atmosphere, they trap heat and contribute to global warming. This increased global temperature leads to the melting of ice shelves and glaciers. One of the primary effects of carbon emissions on ice shelves is the acceleration of their melting rates. Higher atmospheric temperatures cause more ice to melt, which in turn increases the amount of water flowing into the ocean. This added influx of freshwater can disrupt the delicate balance between the ice shelf and the ocean, potentially leading to ice shelf collapse. Additionally, carbon emissions contribute to the thinning of ice shelves. As the atmosphere warms, the air temperature above the ice shelves rises, leading to increased surface melting. This meltwater then flows into crevasses and cracks, causing further fracturing and weakening of the ice shelves. Over time, this thinning can make the ice shelves more susceptible to breaking apart. The melting of ice shelves due to carbon emissions also has indirect effects on the stability of surrounding ice sheets. Ice shelves act as a buttress, providing resistance to the flow of ice from the glaciers into the ocean. When ice shelves collapse or thin, this resistance is diminished, allowing glaciers to flow more freely into the ocean. This process leads to increased sea level rise, which has significant implications for coastal regions around the world. Furthermore, the loss of ice shelves can disrupt the ecosystem and biodiversity of the surrounding areas. Ice shelves provide a platform for various species, including seals and penguins, to breed and feed. When ice shelves disintegrate, these habitats are destroyed, impacting the entire food chain and ecosystem dynamics. Overall, carbon emissions from human activities have profound effects on the stability of ice shelves. The melting, thinning, and collapse of ice shelves contribute to rising sea levels, disrupt ecosystems, and have far-reaching consequences for coastal communities. It is crucial to mitigate carbon emissions and take proactive measures to protect these vulnerable ice shelves and the delicate balance they maintain in our global climate system.

- Q: Is carbon a metal or non-metal?

- Located in group 14 of the periodic table, carbon is classified as a non-metal. Contrary to metals, non-metals possess properties that are typically the opposite, such as poor conductivity of heat and electricity, low melting and boiling points, and brittleness. Carbon, in particular, is renowned for its capacity to generate an array of allotropes, notably graphite and diamond. Although these allotropes exhibit distinct physical and chemical traits, they all share the common attribute of being non-metals.

- Q: How is carbon used in the production of plastics?

- Plastics heavily rely on carbon, an indispensable ingredient, for their manufacturing. These polymers consist of extensive chains formed by repeating units, known as monomers. These monomers, in turn, consist of smaller molecules. Carbon atoms constitute a vital element in these monomers, serving as the foundation for the polymer chain. To acquire carbon for plastic production, diverse petroleum products, like crude oil and natural gas, are sourced. These fossil fuels contain hydrocarbons, which are organic compounds comprised of carbon and hydrogen atoms. Through a refining process called cracking, hydrocarbons are broken down into smaller molecules, including ethylene and propylene, which serve as the basic building blocks for numerous plastic types. Once these monomers are acquired, they are polymerized, meaning they are chemically bonded together to create lengthy chains. Carbon atoms play a critical role in this procedure, as they connect to shape the backbone structure of the polymer chain. The specific arrangement and bonding of carbon atoms dictate the properties of the resulting plastic, including its strength, flexibility, and durability. It is worth noting that while carbon is crucial, not all plastics are exclusively composed of this element. Other elements, such as oxygen, nitrogen, and chlorine, may be present in the monomers or introduced during production to enhance specific properties or introduce desired functionalities. All in all, carbon serves as a fundamental element in plastic production. It establishes the backbone structure, enabling the versatility and wide array of applications of plastic materials across various industries.

- Q: What are the impacts of carbon emissions on the spread of infectious diseases?

- The impacts of carbon emissions on the spread of infectious diseases are significant. Carbon emissions contribute to climate change, which in turn affects various factors that influence the spread of diseases. Rising temperatures, changes in precipitation patterns, and altered ecosystems all play a role in creating favorable conditions for the proliferation and transmission of infectious diseases. These changes can lead to the expansion of disease vectors like mosquitoes, ticks, and rodents, and increase the geographical range of diseases such as malaria, dengue fever, and Lyme disease. Additionally, carbon emissions can weaken human immune systems and exacerbate respiratory illnesses, making individuals more susceptible to infections. Overall, reducing carbon emissions is crucial to mitigate the impacts of climate change and curb the spread of infectious diseases.

- Q: Iron and steel are different in terms of carbon content

- Stainless steel is usually divided according to the structure of the organization, can be divided into austenite, ferrite, martensite and other major categories. If you go into the molten steel of different proportion of Cr Ni austenitic steel, tempered magnet is not stainless steel; if the chromium nickel steel and a small amount to in (or without nickel), tempered steel is a magnet on the stainless steel, also called ferritic stainless steel; martensitic stainless steel alloy the element is chromium, iron and carbon. Stainless steel because of the different alloy content, there are more than 100 kinds. In addition to the austenitic stainless steel magnet not on ferrite and martensitic stainless steel are magnetic. Nickel is scarce in the world and expensive. Therefore, the high nickel content of stainless steel in the market price is higher, but the magnet still can not suck. In fact, there is also a stainless steel magnet can not be sucked.

- Q: What are the consequences of increased carbon emissions on forest ecosystems?

- Increased carbon emissions have a range of negative consequences on forest ecosystems. Firstly, higher levels of carbon dioxide in the atmosphere contribute to global warming, leading to higher temperatures and altered precipitation patterns, which can negatively impact the growth and health of forest plants. Additionally, increased carbon dioxide levels can stimulate the growth of invasive plant species, leading to competition and reduced biodiversity. Moreover, carbon emissions contribute to ocean acidification, which can harm marine ecosystems that are interconnected with forests. Lastly, increased carbon emissions can intensify the frequency and severity of wildfires, posing a significant threat to forest ecosystems and their ability to regenerate.

- Q: How does carbon affect the formation of volcanic eruptions?

- Carbon can play a significant role in the formation of volcanic eruptions. One way carbon affects volcanic eruptions is through the process of degassing. When magma rises to the surface, it carries dissolved gases, including carbon dioxide, with it. As the magma moves towards the surface and pressure decreases, the dissolved gases start to come out of solution, creating gas bubbles within the magma. These gas bubbles can cause the magma to become more buoyant, making it easier for it to rise and eventually lead to an eruption. Additionally, carbon can also influence the viscosity of magma, which is a measure of its resistance to flow. Magma with higher carbon content tends to have lower viscosity, meaning it is more fluid-like and can flow more easily. This lower viscosity allows the magma to move more rapidly towards the surface, increasing the likelihood of an eruption. Furthermore, carbon can also contribute to the explosiveness of volcanic eruptions. When magma reaches the surface, it can interact with organic matter, such as plant material or fossil fuels, which are rich in carbon. This interaction can lead to the combustion of the organic matter, releasing additional gases, such as methane, which can further increase the pressure within the volcano. This increased pressure can result in more explosive eruptions. Overall, carbon has a significant impact on the formation of volcanic eruptions. It affects the buoyancy of magma, its viscosity, and can contribute to the explosiveness of eruptions. Understanding the role of carbon in volcanic processes is crucial for predicting and mitigating the risks associated with volcanic activity.

- Q: How does carbon affect the formation of ground-level ozone?

- Carbon does not directly affect the formation of ground-level ozone. Ground-level ozone is primarily formed through a complex chemical reaction involving oxides of nitrogen (NOx), volatile organic compounds (VOCs), sunlight, and heat. However, carbon-based compounds, such as hydrocarbons, can indirectly impact the formation of ground-level ozone. When carbon-based compounds, like hydrocarbons, are emitted into the atmosphere from sources such as vehicles, industrial processes, and fossil fuel combustion, they can react with nitrogen oxides in the presence of sunlight to form ozone. This reaction occurs in the presence of volatile organic compounds (VOCs) and nitrogen oxides (NOx), which are the primary precursors of ground-level ozone. Elevated levels of carbon-based compounds, particularly in the presence of NOx and sunlight, can enhance the formation of ground-level ozone. This is because the carbon-based compounds act as catalysts, accelerating the chemical reactions that lead to ozone formation. Additionally, the combustion of carbon-based fuels, such as gasoline and diesel, releases nitrogen oxides into the atmosphere, which can further contribute to the formation of ground-level ozone. It is important to note that carbon-based compounds alone do not directly cause ground-level ozone pollution. Rather, they contribute to the formation of ground-level ozone when combined with other pollutants, such as nitrogen oxides and sunlight. To mitigate the formation of ground-level ozone, it is necessary to reduce emissions of carbon-based compounds, as well as other ozone precursors like nitrogen oxides and volatile organic compounds.

- Q: How is carbon used in the steel industry?

- Carbon is a crucial element in the steel industry as it plays a vital role in the production of steel. The addition of carbon to iron is the fundamental process that transforms iron into steel. By combining iron with a controlled amount of carbon, the steel industry is able to achieve the desired properties such as hardness, strength, and durability. Carbon is primarily used as an alloying element in steelmaking, where it enhances the mechanical properties of steel. The carbon content in steel can vary from as low as 0.1% to as high as 2%, depending on the desired steel grade and application. Low carbon steel, with a carbon content of less than 0.3%, is commonly used for applications that require good formability and weldability, such as automotive bodies and construction materials. On the other hand, high carbon steel, with a carbon content of above 0.6%, is used for applications that require high strength and hardness, such as cutting tools, drill bits, and springs. The presence of carbon in these applications allows for increased wear resistance and improved mechanical properties. Carbon also plays a crucial role in the heat treatment process of steel. Through a process called carburizing, steel can be heated in the presence of carbon-rich gases or solids to increase the carbon content at the surface. This results in a hardened surface layer with improved wear resistance, while maintaining a tough and ductile core. Furthermore, carbon is essential for the steel industry's use of electric arc furnaces (EAFs) in steelmaking. EAFs utilize electricity to melt scrap steel and other raw materials. During this process, carbon is introduced to reduce the oxides present in the raw materials, allowing for efficient steel production. In summary, carbon is widely used in the steel industry to achieve the desired properties of steel such as hardness, strength, and durability. Its addition during the steelmaking process and through heat treatment enhances the mechanical properties of steel, allowing for a wide range of applications in various industries.

- Q: I saw a cell phone in the magazine, the global release of 900, no camera, what function is F1 carbon fiber material, actually sold 40000 yuan a piece!.. Everyone said that the circulation is so small, worth so much money? Or carbon fiber material worth so much money?

- Carbon fiber material is very expensive, we are specializing in the production of carbon fiber bicycle accessories company, we know more about this industry.. Such an analogy, an aluminum alloy wheel, that is, the cost of more than 100 yuan, to replace the same carbon fiber material costs more than 1000 of the cost.. Carbon fiber belongs to high-end materials, and foreign countries is to control production, because many weapons and aircraft also use this material, the United States will build weapons in other countries, so are the strict control of each production state of carbon fiber materials..

Send your message to us

Calcined Petroleum Coke Originated in China Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords