Butterfly Valve Steel Threaded Directional with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

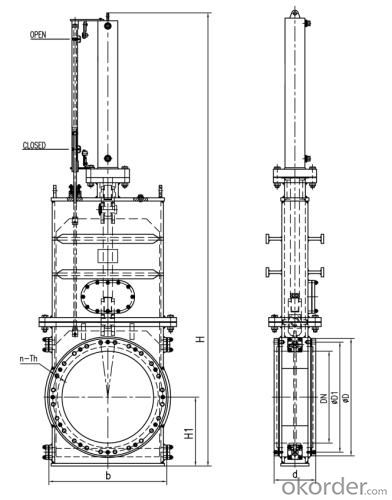

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: For example, the knife gate valve, PZ73X-10C, DN50 torque is 5, torque is what role? What units?

- The opening moment (torque) is the force or torque that must be applied when the valve is opened or closed. Need to open and close the valve when the sealing pressure than the formation of closed and valve seat sealing surface between the two, but also to overcome between the stem and the packing between screw stem and the nut, the valve stem friction end bearing and other friction parts. Therefore, certain closing force and closing torque must be applied, and the required opening and closing force and opening and closing torque during the valve opening process are varied, in which the maximum value is at the closing instant or the initial opening moment. Design and manufacture of valves, should strive to reduce the opening and closing force and opening and closing torque.The open torque can be obtained by means of calculation or measurement, and can be obtained by hand torque measurement.

- Q: What are the valves at home?

- Valve used in the family is commonly used, the following are several:On the water pipe are: total table of the ball valve (32mm), in charge of the (25mm), as well as for the toilet, washbasin, water heater angle valve (20mm).Other commonly used gas pipelines, valves, pressure reducing valves and the like.

- Q: What valve should be used to test the water valve?

- 1, ball valve.2, the water test valve can be ball valve, gate valve, stop valve, installed in the fire sprinkler system at each level of the end of the pipe.

- Q: I would like to ask, how specific treatment, and compared with the industry?.Is there a constructive answer?

- I have to do the technical sales colleagues is high inside out now before the inside sales revenue is also good about one hundred thousand a year as sales of a great degree of luck the.I do not know what the specific circumstances, what age, in this line for several years, there is the opportunity to communicate with the landlord and make progress together.

- Q: What does valve J41H-16C mean?

- J- stop valve4- flange type connection1- structure typeH- alloy steel seal16- nominal pressure 16 kgC- body carbon steel

- Q: What is the choice of pneumatic valve or electric valve for ultrafiltration inlet control valve?

- Now the UF system is basically full automatic system, that is to choose automatic valve. As for the pneumatic valve or electric valve, depending on your investment and the scene.

- Q: What are the other valves used for the control of dual-use items?

- The coding needs to do export dual-use items technical license, this is to go to Beijing for approval for 1 months, I have the electronic key for you to handle, you can also charge electronic keys

- Q: What is called protective valve, and other valves what is the difference?

- Protection valve should be in the air defense valve, can be copper gate valve. (according to the specific use of civil air defense requirements, design institute does not count).2, while the protection valve should be a locking device with the valve, not the general valve can be replaced.

- Q: HH valve company in the United Kingdom, how about the valve?

- Our factory boiler has this brand of valve, used for many years, has been no problem, really good.

- Q: What is the diameter of a general pipe valve?

- What a big pipe? The normal valve clearance is 1cm

Send your message to us

Butterfly Valve Steel Threaded Directional with Plastic Handle

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches