Butterfly Valve Stainless Steel Threaded Directional Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

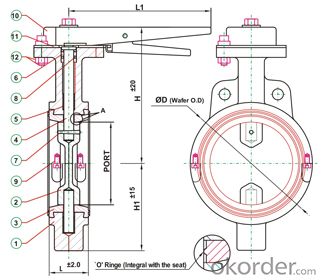

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: What is a lift rod valve?

- Lever valve stem nut in the valve plate, it with the disc (hand wheel) to open the turn, its stem pull the valve head and higher than the valve disk, also known as the bar valve. It is different from the dark rod valve, dark rod valve stem nut in the valve body, when the disc rotates, the stem will not rise.

- Q: What valves are needed on the construction site?

- What he wants to ask is what valve is neededFrom the beginning of the floating ball valve tap water tank, water in front of the gate valve, the soft joint water slurry valve, check valve pipe pressure relief valve to prevent a full set of facilities, water hammer pipe return water pressure high absorb fire safety valve, proportional valve etc.These are the most basic

- Q: Can other valves be used instead of 10?

- An elbow, an outer wire, screw down the joint of the hose, the elbow is joined together.

- Q: What kind of valve is it? How do you see the status of the switch?

- Globe valve, not ball valveClockwise (Bell) needle to reduce the flow to the end of the shutdown, the counter clockwise to open. You can turn the multi circle plate will also lift up and down. The spindle, to the top is open, down to the edge off.The ball valve has a strip handle, the line is connected, and the cross is turned off

- Q: What's the difference between valves and valves without valves?

- The difference between a valve with and without a valve is that it has the advantage of having the valve exhaust. The advantage of the valve is that it can control the amount of exhaust and prevent the discharge of other fluids.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: Is there any problem with connecting the geothermal valves with other geothermal pipes?

- Material is the same, the fuse will not cause shrinkage when you can use

- Q: What's the name of the valve?

- This is the discharge valve, the lower part of the handle protruding part of the valve is the sealing device. The overall material should be brass, which is typically made by equipment manufacturers.

- Q: How do you understand the valve Z41X-16?

- This is a standard set, the landlord himself to check the JB/T308 standard, Baidu library, some, and is free to download:JB/T 308-2004 valve type method of preparation clear EditionZ = gate valve4 = connection: flange1 = structural form: open rod single gateX = sealing surface material: Rubber16 = nominal pressure: 1.6MPa16 there is no letter behind it indicates that the body is made of cast iron

- Q: What is the difference between a stop valve (a power station valve) and other valves?

- Compared with other valve products, the valve is characterized by high temperature and high pressure. If the pressure is lower than that of the universal valve, it is also lower than the common valve. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.The utility model is suitable for cutting off or connecting the pipeline medium on the pipelines of various systems of the fire power plant. Applicable medium: non corrosive media such as water and steam. Compared with other valve products, the valve is characterized by high temperature and high pressure and unique self sealing design. The higher the pressure, the more reliable the seal is. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.

- Q: Why can't the clip type check valve be directly connected with the pipe mouth or other valves?

- The clip type check valve is made up of two discs to prevent backflow.If the clip check valve is connected to the other valve, the disc may touch the valve and cause the check valve not to be fully opened or closed. This is a preliminary analysis of "enter the valve", for reference only!

Send your message to us

Butterfly Valve Stainless Steel Threaded Directional Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords