Building Hoist Single SC270 Middle Speed

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Single SC270 Middle Speed

Driving board

The driving board connects driving unit with driving frame. A rack wheel is installed at its back. Through adjusting the eccentric locking collar of the rack wheel, the clearance between the pinion and the rack can be adjusted to ensure the proper engagement of them( Before leaving our factory, the clearance between the pinion and the rack has been properly adjusted by our engineers), as a result, the cage will run more stable. The connection between the driving board and the driving frame is of float connection, with rubber shim, to reduce mechanical vibration .

Driving frame

The driving frame, bearing all the loading from the cage, is welded with channel steel & steel board and equipped with 6 rollers Inside the roller there is installed eccentric axle and rolling bearing, which can be adjusted separately. The adjustment of eccentric axle will effect the relative position of driving frame and mast. The safety hook is installed on the driving frame, aiming to avoid overturn of the driving frame and disengagement position between pinion and rack. The driving system, as the vital part of the hoist, is composed of the electrical magnetic motors, reducers and driving frame.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

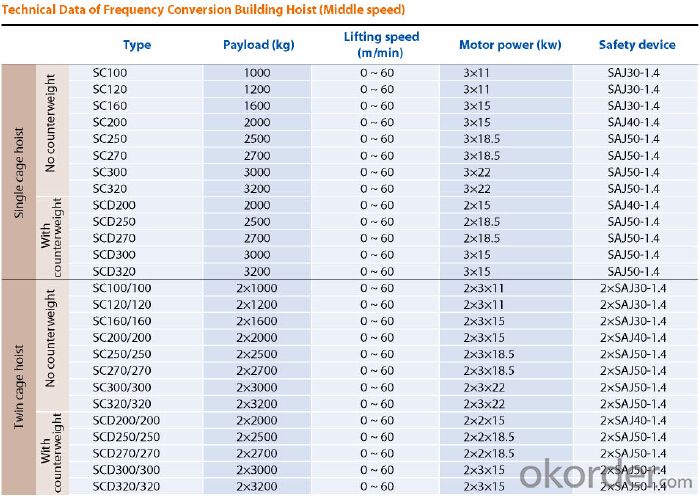

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for the proper usage guidelines for a building hoist, a mechanical device used in construction to lift materials.

- <p>To use a building hoist correctly, follow these steps: Ensure the hoist is inspected and certified for safe operation. Check all safety devices, including limit switches and emergency stops, are functioning. Securely attach the load to the hoist's hook, ensuring it's balanced and within weight limits. Never exceed the hoist's capacity. Operate the hoist with caution, avoiding sudden starts or stops. Keep the hoist area clear of people and obstacles. Use a tag line to guide the load if necessary. Always lower the hoist when not in use and secure it against wind or other forces. Regular maintenance and inspections are crucial to prevent accidents.</p>

- Q: This question asks for measures to protect lifting equipment from damage during its operation.

- <p>To prevent damage to lifting equipment during operation, ensure regular maintenance and inspection are conducted to check for wear and tear. Adhere to the equipment's load limits and never exceed them. Use appropriate lifting techniques and ensure the load is balanced. Keep the equipment clean and free from debris. Train operators thoroughly on safe operating procedures. Avoid sudden starts or stops, and ensure all safety features and guards are in place and functioning correctly. Regularly check cables, hooks, and other critical components for any signs of damage. Always follow the manufacturer's guidelines and industry safety standards.</p>

- Q: What measures can be taken to guarantee the smooth and reliable operation of a building hoist during lifting?

- <p>To ensure the smooth and reliable operation of a building hoist, regular maintenance and inspection are crucial. This includes checking the hoist's mechanical components for wear and tear, ensuring the electrical systems are functioning correctly, and verifying that all safety mechanisms are in place and operational. Additionally, proper lubrication of moving parts, adherence to load limits, and operator training on safety protocols are essential. It's also important to use hoists that meet safety standards and to avoid overloading. Regularly updating and upgrading the hoist system can also enhance reliability and safety.</p>

- Q: This question asks for criteria or factors to consider when selecting the appropriate type of building hoist for a specific construction project.

- <p>Choosing a suitable type of building hoist involves considering several factors: the weight and size of materials to be lifted, the frequency of hoisting, the height of the building, and safety requirements. Assess the load capacity needed, as hoists vary in their lifting capabilities. Consider the hoist's speed and efficiency to ensure it meets the project's timeline. The hoist's size and maneuverability are crucial for fitting within the construction space. Safety features and certifications should be verified to ensure compliance with industry standards. Consulting with hoist manufacturers or rental companies can provide insights into the most suitable hoist for your specific application.</p>

- Q: Does the new approach builder need a localizer test report

- When the distance of the meter cage is not more than the distance shown in the test, the safety device meets the requirements of the relevant specification. You're talking about a construction elevator that's the kind of gear rack that you don't want to have as long as you want to

- Q: This question asks for methods to prevent leakage in hydraulic cylinders used in building hoists.

- <p>To prevent hydraulic cylinder leaks in a building hoist, follow these steps: Regularly inspect and maintain the hydraulic system to ensure all seals and gaskets are in good condition. Replace any worn or damaged components promptly. Ensure the hydraulic oil is clean and at the correct level to avoid air bubbles or cavitation which can cause leaks. Check the cylinder rods for scratches or damage and polish or replace them if necessary. Maintain the correct operating pressure and avoid overloading the hoist. Regularly lubricate moving parts to reduce friction and wear. Implement a routine maintenance schedule to catch and address potential issues before they lead to leaks.</p>

- Q: The construction of more than many floors must be used for construction elevators

- The average height is more than 12 stories. Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. The construction elevator of our country is more and more mature, and gradually goes to the international.

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: What are the primary materials that are commonly utilized in the construction of hoists?

- <p>Hoists are typically constructed using a combination of metals and synthetic materials for strength and durability. Steel, particularly alloy steel, is a common choice due to its high tensile strength and resistance to wear. Aluminum is also used for its lightweight properties, especially in mobile hoists. Synthetic materials such as nylon or polyester are used for hoist ropes and cables due to their resistance to abrasion and corrosion. Additionally, hoists may incorporate components made from brass, bronze, or other metals for specific parts that require low friction or high resistance to corrosion.</p>

- Q: Is the construction elevator the same as the construction elevator

- Construction lifter is a kind of vertical lifting equipment standard name, generally refers to the SC model of the single or double hoisting cage hoisting cage, driven by gear and rack, (in recent years, there are many strands of wire rope drive), equipped with "" for safety device, can people goods with multiplication. The construction elevator is called a popular term, and the common site is called a rack elevator and a human cargo elevator, which means the same thing. Because this kind of product applies only to the construction site, it is very different from the common guest elevator. There are two other types of products that are common to this type of product, such as the SS single-column double cage (wire rope drive), which is called the material lift machine, which cannot be multiplied by people. There is also the WJ series double column single-cage (wire rope drive), which is called the dragon door frame, which is also not allowed to be passenger. Strictly speaking, the latter two kinds can't be called construction elevator, can be called so-and-so elevator. Above is a person's humble opinion, if be in and out, still hope the expert is correct!

Send your message to us

Building Hoist Single SC270 Middle Speed

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords