Construction Hoist SC100 Middle Speed Factory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC100 Construction Hoist Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SC100 Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SC100 Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 0~60 | 3*11 | SAJ30-1.4 |

| SC120 | 1200 | 0~60 | 3*11 | SAJ30-1.4 | ||

| SC160 | 1600 | 0~60 | 3*15 | SAJ30-1.4 | ||

| SC200 | 2000 | 0~60 | 3*15 | SAJ40-1.4 | ||

| SC250 | 2500 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC270 | 2700 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC300 | 3000 | 0~60 | 3*22 | SAJ50-1.4 | ||

| SC320 | 3200 | 0~60 | 3*22 | SAJ50-1.4 | ||

| With Counterweight | SCD200 | 2000 | 0~60 | 2*15 | SAJ40-1.4 | |

| SCD250 | 2500 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD270 | 2700 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD300 | 3000 | 0~60 | 3*15 | SAJ50-1.4 | ||

| SCD320 | 3200 | 0~60 | 3*15 | SAJ50-1.2 |

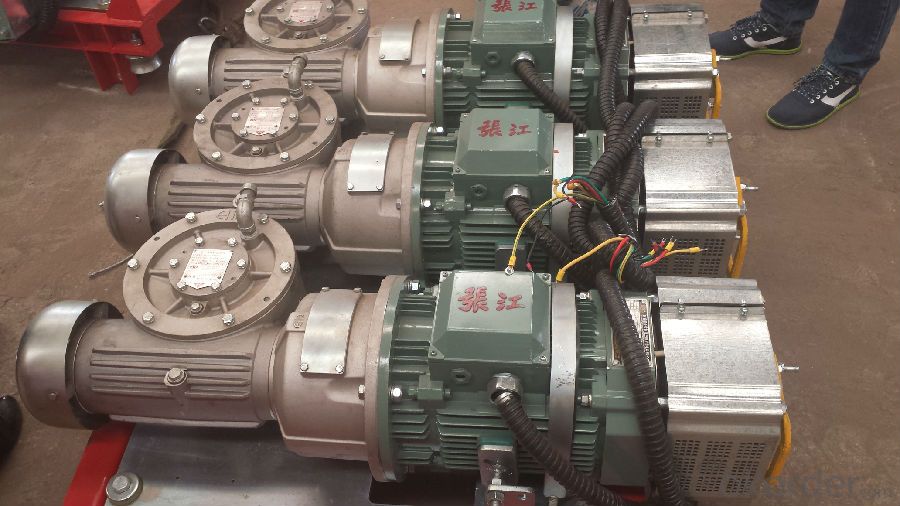

Images of SC100 Construction Hoist

FAQ of SC100 Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: How does the construction lift fall without electricity

- This is not calculated according to the distance, it is calculated speed, when the anti-pendant achieves the rated speed, the pendant should be held automatically. It can't go on.

- Q: Is it possible to utilize a building hoist for the purpose of lifting heavy equipment or machinery?

- <p>Yes, a building hoist can be used for lifting heavy equipment or machinery, provided it has the necessary capacity and safety features. These hoists are designed to handle substantial loads and are commonly used in construction for moving materials and equipment. However, it's crucial to ensure that the hoist is rated for the weight of the equipment, and all safety protocols are followed to prevent accidents. Regular maintenance and inspection are also essential to ensure the hoist's reliability and safety during heavy lifting operations.</p>

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: This question asks if a building hoist can be utilized to lift various types of materials including wood, steel, and concrete.

- <p>Yes, building hoists are designed to lift a variety of materials. They are commonly used in construction to transport materials such as wood, steel, and concrete between different floors. However, it's important to ensure that the hoist is appropriately rated for the weight of the materials being lifted and that safety protocols are followed. Each material may require specific handling techniques or attachments to secure the load properly and prevent damage or accidents.</p>

- Q: Is it possible to replace an electric control panel with a manual lever in a lifting system?

- <p>While it is theoretically possible to use a manual lever as a substitute for an electric control panel in a lifting system, it is not advisable. Manual levers lack the precision, safety features, and control capabilities of electric control panels. They also cannot provide the same level of feedback or automation. Electric control panels are designed to ensure safe and efficient operation, with features like emergency stop buttons, overload protection, and remote monitoring. Manual levers can pose safety risks and may not meet the operational requirements of modern lifting systems.</p>

- Q: What are alternative uses for a building hoist besides construction?

- <p>Yes, a building hoist can be used for purposes other than construction. It can be utilized for moving heavy equipment in industrial settings, transporting goods in warehouses, or even in emergency services for rescue operations. Its ability to lift and lower heavy loads makes it versatile for various applications where vertical transportation is required. However, it's crucial to ensure that any alternative use complies with safety regulations and the hoist's operational specifications.</p>

- Q: This question asks whether a building hoist can be utilized for lifting various kinds of objects.

- <p>Yes, a building hoist can be used for lifting multiple types of objects. It is designed to handle a variety of materials, including construction materials, tools, and equipment. The hoist's capacity and design may vary, allowing it to accommodate different weights and sizes. However, it is crucial to ensure that the hoist's lifting capacity is not exceeded and that the objects are secured properly to prevent accidents. Always refer to the manufacturer's guidelines for specific weight limits and safety procedures.</p>

- Q: This question asks for a comparison of vertical and horizontal lifting in the context of building hoists, highlighting their distinct characteristics.

- <p>Vertical lifting in a building hoist refers to the movement of materials directly up or down, which is essential for transporting goods between different floors or levels of a building under construction. Horizontal lifting, on the other hand, involves moving materials across a horizontal plane, which is useful for moving items along a floor or between different parts of a construction site. Vertical lifting is typically more common in hoists due to the nature of building construction, requiring frequent vertical transport. Horizontal lifting is less common but can be implemented with specialized equipment or by combining vertical and horizontal movements. The choice between vertical and horizontal lifting depends on the specific requirements of the construction project and the layout of the site.</p>

- Q: This question asks for criteria to differentiate between electric and hydraulic building hoists for selection based on specific needs.

- <p>When choosing between electric and hydraulic building hoists, consider the following: 1) Power Source: Electric hoists require a reliable electricity supply while hydraulic hoists need a power source for the hydraulic pump. 2) Lifting Capacity: Electric hoists often have higher lifting capacities. 3) Speed: Electric hoists generally offer faster lifting and lowering speeds. 4) Maintenance: Hydraulic hoists may require more frequent maintenance due to fluid changes and potential leaks. 5) Noise: Electric hoists are quieter. 6) Cost: Initial costs and operating expenses should be compared. 7) Safety: Both types have safety features, but electric hoists might offer more advanced safety options. 8) Environmental Factors: Consider weather conditions; electric hoists are less affected by rain and cold. Your choice should align with the project's specific requirements, such as the weight of materials to be lifted, frequency of use, and environmental conditions.</p>

- Q: This question asks for the steps or methods to keep a building hoist in good condition and fix any damages.

- <p>To maintain and repair a damaged building hoist, follow these steps: Regularly inspect the hoist for wear and tear, checking cables, pulleys, and brackets. Lubricate moving parts to reduce friction and prevent rust. Replace damaged or worn-out components promptly. Ensure all safety features are functioning correctly. If a hoist is severely damaged, consult with a professional to assess the damage and perform necessary repairs. Always adhere to the manufacturer's guidelines and safety regulations during maintenance and repair processes.</p>

Send your message to us

Construction Hoist SC100 Middle Speed Factory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords