Building Hoist SC120 Middle Speed for Passenger

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):1200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*11

Safety Device: SAJ30-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC120

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Anchorage System

Mast Section

Driving Unit

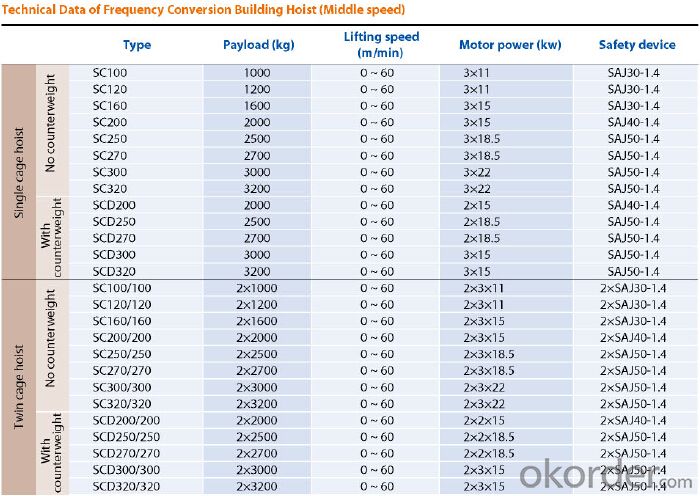

Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for the purpose of lifting heavy equipment or machinery?

- <p>Yes, a building hoist can be used for lifting heavy equipment or machinery, provided it has the necessary capacity and safety features. These hoists are designed to handle substantial loads and are commonly used in construction for moving materials and equipment. However, it's crucial to ensure that the hoist is rated for the weight of the equipment, and all safety protocols are followed to prevent accidents. Regular maintenance and inspection are also essential to ensure the hoist's reliability and safety during heavy lifting operations.</p>

- Q: This question asks for a comparison of the pros and cons of utilizing hydraulic cylinders in the context of building hoists.

- <p>Hydraulic cylinders in building hoists offer several advantages, including high force output, compact size, and precise control. They provide smooth and controlled lifting, which is crucial for heavy construction materials. Additionally, hydraulic systems can generate large amounts of force with relatively small cylinders, making them space-efficient. The disadvantages include potential leaks, which can be hazardous, and the need for regular maintenance to ensure the system's reliability. Hydraulic systems can also be more complex to install and repair compared to electric or manual systems. Furthermore, they require a constant power source, which might not always be readily available on construction sites.</p>

- Q: Can construction elevators be taken by people or by goods

- According to GB 26557-2011, "a vertical guide for people with vertical navigation". 5.6 lift cage 5.6.1 general When the maximum number of passengers can be carried, the maximum amount of the ceiling shall be calculated according to the area of 0.2 square meters per person, and the weight should be calculated at 75 kg per person.

- Q: Excuse me: what is the meaning of heavy weight in the construction elevator?

- With double cage for heavy, namely SCD200/200 series Is the two cages, each cage has a corresponding weight, the weight up and down in the elevator cage rise to energy conservation and reduce the reaction between the up and down, when you imagine front-rear door principle is about the same

- Q: This question asks for examples of typical uses for building hoists, which are devices used to lift materials in construction settings.

- <p>Building hoists are commonly used in various construction applications. They are utilized for lifting and lowering materials and personnel in high-rise construction projects. Some examples include: 1) Lifting building materials such as bricks, cement, and steel beams to different floors of a building under construction. 2) Transporting workers to elevated work areas for tasks like scaffolding assembly or window installation. 3) Moving heavy equipment to upper levels of a structure. 4) Assisting in the installation of large fixtures like HVAC systems or electrical wiring systems. 5) Facilitating the removal of construction waste from upper floors. These applications highlight the versatility and efficiency of building hoists in construction projects.</p>

- Q: Is it possible to use personal lifting equipment for lifting extremely heavy objects?

- <p>Using your own lifting equipment to lift very heavy objects can be possible, but it depends on the weight capacity and safety standards of your equipment. Always ensure that your lifting gear is rated for the weight you intend to lift and that it is in good working condition. Additionally, it's crucial to follow all safety protocols, including proper setup, securing the load, and using personal protective equipment. For extremely heavy objects, professional lifting services are often recommended to ensure safety and prevent accidents.</p>

- Q: When does the construction elevator take off?

- Generally in roof waterproof thermal insulation engineering, interior decoration engineering basic completion, outdoor decoration project is approaching to the end, began to dismantle scaffold outside of time.

- Q: How much cable does the construction elevator 44KVA need?

- 44KW three phase power: 79A, BV5X16

- Q: This question asks about the safety measures that should be taken to ensure the safe operation of a building hoist during lifting.

- <p>To ensure the safety of the lifting operation of a building hoist, several key measures should be taken: Regular inspection and maintenance of the hoist equipment to ensure all components are in good working order. Adherence to the manufacturer's guidelines and safety standards for operation. Proper training for operators to ensure they understand how to use the hoist safely. Implementing a safety checklist before each use. Ensuring the load is secured properly and does not exceed the hoist's weight capacity. Using appropriate safety gear such as safety harnesses and helmets. Having a spotter or signal person to assist the operator and watch for potential hazards. Regularly checking the weather conditions to avoid operating in high winds or other adverse weather that could compromise safety.</p>

- Q: The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- There are no rules for the distance between tower crane and construction elevator, but note the following points: (1) the foundation of the tower crane and the construction elevator cannot affect each other; (2) the construction elevator shall not be higher than the tower crane. (3) the location of the elevator shall not be blocked by the position of the construction elevator; (4) the use of the same circuit and the same distribution box with the construction elevator shall not be used by the tower crane. The distance between the tower crane and the construction elevator can be anywhere, as long as the above aspects are met.

Send your message to us

Building Hoist SC120 Middle Speed for Passenger

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords