Building Hoist SCD200/200 Construction Hoist High Quaity

- Loading Port:

- China Main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

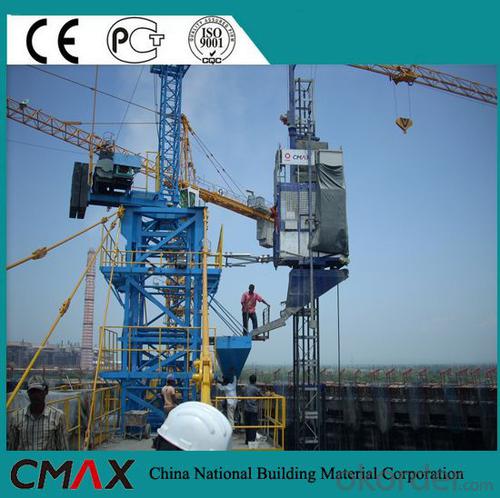

Structure of Building Hoist SCD200/200 Description

The construction hoist product produced by Fangyuan has achieved internationally advanced level in terms of industrial design, control and the drive performance, as well as the operation safety and comfortableness.

And Fangyuan is also making efforts to keep improving the product, as what the construction hoist lifts is not only people and material, but also a kind of social responsibility and service concept…

The new generation SC series of construction hoists adopt modular structure, ergonomic design and advanced manufacturing technology, thus the adaptability and reliability of the product is greatly improved, e.g. the max. lifting height can reach 300 meters.

The product adopts multiple patented technologies, reaches advanced level in China, and the market share in domestic market is increasing year by year.

The product has also been exported to overseas countries like Russia, Turkmenstan, Vietnam, etc. winning the confidence of customers of both home and abroad

Main features of Building Hoist SCD200/200

1. The cage drive system is equipped with buffering device, so the cage moves more stable.

2. The ergonomically designed cage interior improves comfortableness.

3. The unique structural design has applied for patent.

4. The typical technologies ensure the malposition difference of the guide rail.

5. The excellent parts in the industry ensures reliable quality of the machine.

6. Precise assembly and accurate drive.

7. Professional solutions for special projects.

8. The complete safety devices ensures reliable control system.

Construction Hoist Building Hoist SCD200/200 Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage construction elevator can be changed into single cage type, such as SCD200.

Model | SC200/200 | SC200/200BP | SCD200/200 | SC200/200B | ||

Configuration | Standard type | Frequency conversion | Counterweight type | Export type | ||

Rated load | kg | 2000/2000 | 2000/2000 | 2000/2000 | 2000/2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 16/16 | 16/16 | 16/16 | ||

Max.lifting height | m | 150 | 300 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 0~60 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | ||||

Electric motor | Type | Disc brake electic motor | ||||

Power | kW | 11×3/11×3 | 11×3/11×3 | 11×2/11×2 | 11×3/11×3 | |

Speed limiter | Action speed | m/s | 1.2 | 1.45 | 1.2 | 1.2 |

Rated brake load | kN | 40 | 40 | 30 | 40 | |

Model | SCD200/200B | SC100/100 | SCD200 | ||

Configuration | Counterweight type | No counterweight | Counterweight type | ||

Rated load | kg | 2000/2000 | 1000/1000 | 2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 12/12 | 16 | ||

Max.lifting height | m | 150 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | |||

Electric motor | Type | Disc brake electic motor | |||

Power | kW | 11×2/11×2 | 11×2/11×2 | 11×2 | |

Speed limiter | Action speed | m/s | 1.2 | 1.2 | 1.2 |

Rated brake load | kN | 30 | 30 | 30 | |

The above parameters are subject to change without prior notice, please refer to the actual product.

Note: Both cage size of 3×1.3×2.2 and 3.2×1.5×2.4 are available for of each model (Excl. export type).

Images of Building Hoist SCD200/200

FAQ of Construction Hoist Building Hoist SCD200/200

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to utilize a building hoist for the purposes of renovation projects?

- <p>Yes, a building hoist can be used for renovation work. These hoists are designed to lift and lower materials and personnel efficiently, making them ideal for construction and renovation projects. They help in moving heavy materials such as bricks, cement, and tools to different floors without the need for manual labor, thus increasing safety and productivity. However, it's crucial to ensure that the hoist is properly installed, maintained, and operated by trained personnel to avoid accidents and ensure the safety of all involved.</p>

- Q: How many guides are in the construction elevator

- 1 guide frame is 1508cm, the highest can be 400 meters

- Q: Is it possible to use a building hoist to lift various materials simultaneously?

- <p>Yes, a building hoist can be used for lifting multiple materials at once, provided the total weight does not exceed the hoist's load capacity. It's crucial to ensure that the materials are securely fastened and balanced to prevent tipping or damage. Always follow the manufacturer's guidelines and safety regulations to avoid accidents and ensure the safe operation of the hoist.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: How to adjust the weight limit of the construction elevator

- It's very simple, there's a couple of buttons down here, okay

- Q: This question asks for a comparison between electric and electric-hydraulic building hoists, highlighting their distinct features and how they differ from each other.

- <p>Electric building hoists are powered solely by electric motors, which provide direct and precise control over the lifting and lowering of loads. They are quieter, require less maintenance, and are more energy-efficient compared to their hydraulic counterparts. On the other hand, electric-hydraulic building hoists combine the power of an electric motor with the force amplification capabilities of hydraulic systems. These hoists offer greater lifting capacity and can handle heavier loads but are generally more complex, requiring regular maintenance of hydraulic components. They are also louder and may consume more energy. The choice between the two often depends on the specific requirements of the lifting task, such as load capacity, precision, and environmental considerations.</p>

- Q: This question asks about the time required to install a building hoist, a device used for lifting materials in construction.

- <p>The time it takes to install a building hoist can vary significantly based on factors such as the type and size of the hoist, the specific building requirements, and the experience of the installation team. On average, it can take anywhere from a few hours to a couple of days. For smaller hoists, installation might be completed within a day, while larger, more complex systems could take longer. It's important to note that safety checks and regulatory compliance verifications are also part of the process, which can add to the total installation time.</p>

- Q: How is the construction elevator installed

- This is normally installed by professional unit, oneself outfit not to be able, the security check check has a problem. And you don't install it yourself, you don't have a big safety accident. Installation process typically do first base, standard section is installed on the ground, hanging cage, outside guardrail, hanging basket to open up, the installation of the standard section of the upper portion, helped wall, fence and so on, the final debugging, acceptance, complete

- Q: Is it possible to utilize a single-rope lifting system in the context of a building hoist?

- <p>Yes, a single-rope lifting system can be used in a building hoist. This system is common in construction elevators, where a single rope is used to lift and lower the hoist's cage. The rope is attached to a motor at the top and passes over sheaves or pulleys to provide mechanical advantage. It is essential to ensure that the rope is strong enough to support the load and that the system is equipped with safety features such as overload protection and emergency braking mechanisms to prevent accidents.</p>

- Q: Is it possible to replace a motor in a building hoist with a hydraulic cylinder?

- <p>While a hydraulic cylinder can provide linear motion and force, it is not a direct substitute for a motor in a building hoist. Hydraulic cylinders are used for lifting and pushing applications, but they lack the variable speed and control that a motor provides. Motors, especially electric ones, offer precise control, variable speed, and efficiency which are critical for hoisting operations. A hydraulic system would require additional components like pumps and valves for control, making it more complex and less energy-efficient compared to an electric motor system. Therefore, a hydraulic cylinder alone is not suitable as a direct replacement for a motor in a building hoist.</p>

Send your message to us

Building Hoist SCD200/200 Construction Hoist High Quaity

- Loading Port:

- China Main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords