Building Hoist SC300/300 Lifting Payload 2*3000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

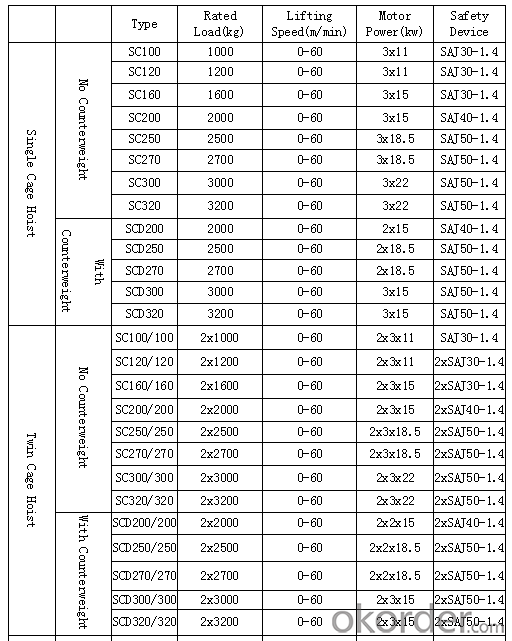

Payload(kg):2*3000 Lifting Speed(m/min):0~60 Motor Power(kw): 2*3*22

Safety Device: 2*SAJ50-1.4 Cage: Twin Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SC300/SC300

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Overload Limiter

Mast Section

Driving Unit

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a list of various types of lifting equipment commonly used in the construction industry.

- <p>In construction, various types of lifting equipment are utilized to move heavy materials and structures. These include cranes such as tower cranes, mobile cranes, and crawler cranes, which are versatile and can lift heavy loads to significant heights. Forklifts are used for lifting and moving materials over short distances. Telescopic handlers, also known as cherry pickers, provide both lifting and access capabilities. Hoists are used for lifting smaller loads and are often found in workshops or on construction sites. Derricks are fixed structures used for lifting heavy loads in a specific area. Lifting slings and shackles are used in conjunction with cranes and hoists to secure loads. Finally, aerial work platforms, like scissor lifts and boom lifts, provide elevated access for workers and materials. Each type of lifting equipment serves a specific purpose and is chosen based on the nature of the construction project and the weight and size of the loads to be moved.</p>

- Q: Is it permissible to utilize personal lifting gear for the purpose of lifting objects?

- <p>Yes, you can use your own lifting equipment to lift objects, provided it meets safety standards and is suitable for the weight and type of objects being lifted. Always ensure that the equipment is in good working condition, and you are trained in its proper use to prevent accidents. Compliance with local regulations and guidelines is also crucial to avoid any legal repercussions.</p>

- Q: This question asks for the steps or procedures to keep a building hoist in good working condition.

- <p>Maintaining a building hoist involves regular inspections, lubrication, and repairs. Ensure all safety features are operational and that the hoist is clean and free of debris. Check cables for wear and replace them if necessary. Lubricate moving parts as per the manufacturer's recommendations. Inspect the electrical system for any signs of damage or wear. Regularly test the hoist's load capacity and emergency stop functions. Keep a maintenance log to track all inspections and repairs. If any issues are identified, address them promptly to prevent accidents and ensure the hoist operates safely and efficiently.</p>

- Q: A building hoist is a mechanical device used in construction to lift materials and sometimes workers vertically. It is essential for the efficient movement of materials in high-rise construction.

- <p>The function of a building hoist is to facilitate the vertical transportation of materials, equipment, and sometimes workers within a construction site. It is particularly useful in high-rise buildings where manual lifting would be inefficient and unsafe. A building hoist allows for the rapid and safe movement of materials, reducing labor costs and improving construction speed.</p>

- Q: Is it possible to utilize a single-rope lift as an alternative to a building hoist for the purpose of lifting materials or individuals?

- <p>While theoretically possible to use a single-rope lift for lifting materials or people, it is not advisable or practical for construction purposes. Building hoists are specifically designed for construction sites, offering safety features, load-bearing capacities, and stability that single-rope lifts typically lack. Single-rope lifts are more suited for simple, controlled environments and are not equipped to handle the heavy loads, frequent use, or varied conditions of a construction site. The use of a building hoist is recommended for safety, efficiency, and compliance with construction regulations.</p>

- Q: Is it possible to use a lifting device to assist in lifting an individual who is too tall for one person to lift safely?

- <p>Yes, you can use a lifting device to assist in lifting someone who is too tall for you to lift alone. These devices are designed to help in safely moving individuals who are heavier or taller than can be managed without assistance. It's important to ensure that the lifting device is appropriate for the person's weight and height, and that it is used correctly to avoid injury. Always follow the manufacturer's instructions and safety guidelines when using such equipment.</p>

- Q: This question inquires about the cost of a hydraulic building hoist.

- <p>The cost of a hydraulic building hoist can vary significantly depending on factors such as capacity, brand, features, and new or used condition. Prices typically range from a few thousand dollars for smaller, basic models to tens of thousands for larger, more advanced units. For a precise quote, it's best to contact manufacturers or suppliers with specific requirements, as costs can fluctuate based on the model and market conditions. It's also advisable to consider ongoing maintenance and operational costs when budgeting for a hydraulic building hoist.</p>

- Q: What is the capacity range of a building hoist in terms of lifting objects?

- <p>A building hoist can be used for lifting both large and small objects, depending on its design and capacity. These hoists are engineered to handle various weights, typically ranging from a few hundred pounds to several tons. The specific size and weight of the objects that can be lifted are determined by the hoist's lifting capacity, which is a crucial factor to consider when selecting a hoist for a particular job. It's important to ensure that the hoist's capacity exceeds the weight of the objects to be lifted for safety and efficiency.</p>

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

- Q: Is it safe to use a lifting device with someone who has no experience with it?

- <p>It is generally not advisable to use a lifting device with someone who is not familiar with it. Lifting devices require proper training and understanding of their operation to ensure safety. Using such equipment without proper knowledge can lead to accidents and injuries. It is crucial to ensure that anyone operating a lifting device has received the necessary training and is familiar with the specific device's safety protocols and operation procedures.</p>

Send your message to us

Building Hoist SC300/300 Lifting Payload 2*3000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords