Building Hoist SCD200/200 Lifting Payload 2*2000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2*2000 Lifting Speed(m/min):0~60 Motor Power(kw): 2*2*15

Safety Device: 2*SAJ40-1.4 Cage: Twin Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD200/200

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Hoist Factory

Mast Section

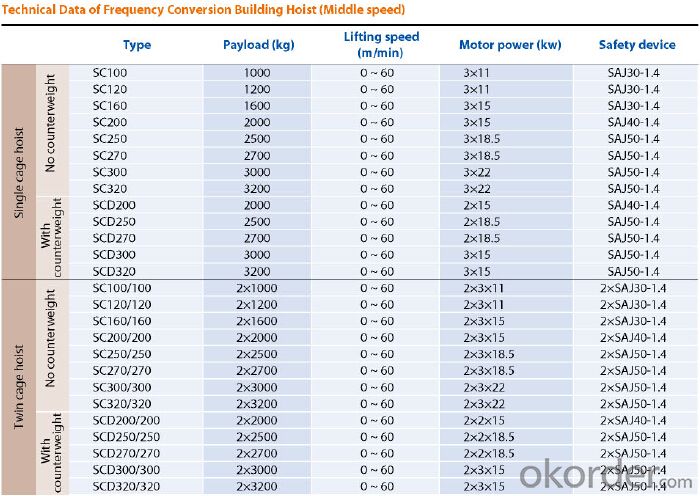

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Safe use of construction elevator

- 1, seek professional installation. 2, pay attention to safety when using, don't worry, because the elevator is not as fast as the elevator. 3, if there is a broken part, change it quickly, don't delay and feel free

- Q: This question asks for a description of the process of using an emergency stop button specifically in the context of a building hoist.

- <p>To use an emergency stop button on a building hoist, first, ensure you are familiar with the hoist's controls and safety features. Locate the emergency stop button, which is typically a red mushroom-shaped button or switch, prominently placed and easily accessible. In an emergency, press and hold the button firmly. This action will immediately stop all hoist functions, including movement and operation. After pressing the emergency stop, evacuate the area if necessary and notify the appropriate personnel to address the situation. Remember, the emergency stop should only be used in situations where immediate action is required to prevent harm or damage. Regular training and drills can help ensure you are prepared to use the emergency stop button correctly and effectively.</p>

- Q: This question asks for examples of typical uses for building hoists, which are devices used to lift materials in construction settings.

- <p>Building hoists are commonly used in various construction applications. They are utilized for lifting and lowering materials and personnel in high-rise construction projects. Some examples include: 1) Lifting building materials such as bricks, cement, and steel beams to different floors of a building under construction. 2) Transporting workers to elevated work areas for tasks like scaffolding assembly or window installation. 3) Moving heavy equipment to upper levels of a structure. 4) Assisting in the installation of large fixtures like HVAC systems or electrical wiring systems. 5) Facilitating the removal of construction waste from upper floors. These applications highlight the versatility and efficiency of building hoists in construction projects.</p>

- Q: A building hoist is a piece of equipment used in construction to lift materials and personnel.

- <p>A building hoist, also known as a construction hoist or material hoist, is a temporary lifting device used in the construction industry to transport materials, equipment, and sometimes personnel vertically within a building under construction. It is essential for efficient movement of heavy and bulky items, reducing manual labor and improving safety by minimizing the need for workers to climb ladders or handle heavy loads manually. These hoists are typically installed on the exterior of the building and are used throughout the construction process until the building's permanent elevators are installed and operational.</p>

- Q: Is it possible to replace an electric control panel with a manual lever in a lifting system?

- <p>While it is theoretically possible to use a manual lever as a substitute for an electric control panel in a lifting system, it is not advisable. Manual levers lack the precision, safety features, and control capabilities of electric control panels. They also cannot provide the same level of feedback or automation. Electric control panels are designed to ensure safe and efficient operation, with features like emergency stop buttons, overload protection, and remote monitoring. Manual levers can pose safety risks and may not meet the operational requirements of modern lifting systems.</p>

- Q: Is it advisable to use personal lifting equipment without seeking professional advice first?

- <p>No, it is not advisable to use your own lifting equipment without consulting professionals first. Lifting operations can be hazardous and require specific knowledge and expertise to ensure safety. Professionals can assess the weight, stability, and appropriate lifting techniques required for your equipment. They can also provide guidance on safety regulations and the correct use of lifting gear, which is crucial to prevent accidents and injuries. Always consult with experts before undertaking any lifting tasks to ensure compliance with safety standards and to protect yourself and others.</p>

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: Is it permissible to utilize electric or hydraulic building hoists in personal workshops or factories?

- <p>Yes, you can use an electric or hydraulic building hoist in your own workshop or factory. However, you must ensure that the hoist complies with local safety regulations and standards. It's crucial to have the hoist installed by qualified professionals and to maintain it regularly to prevent accidents. Always follow the manufacturer's guidelines and safety protocols to ensure the safe operation of the hoist.</p>

- Q: What precautions should be taken when operating a building hoist to ensure safety?

- <p>Safety measures for using a building hoist include ensuring the hoist is regularly inspected and maintained, following the manufacturer's guidelines. Operators must be trained and certified. Load limits must be strictly adhered to, and the hoist should not be overloaded. A safety cage or gate should be in place to prevent accidental falls. Emergency stop switches should be easily accessible. Regular inspections for wear and tear, especially on cables and hooks, are crucial. Never use a hoist if it shows signs of damage or malfunction. Always secure loads properly to prevent them from shifting during transport.</p>

- Q: Is it safe to use a lifting device with someone who has no experience with it?

- <p>It is generally not advisable to use a lifting device with someone who is not familiar with it. Lifting devices require proper training and understanding of their operation to ensure safety. Using such equipment without proper knowledge can lead to accidents and injuries. It is crucial to ensure that anyone operating a lifting device has received the necessary training and is familiar with the specific device's safety protocols and operation procedures.</p>

Send your message to us

Building Hoist SCD200/200 Lifting Payload 2*2000kg

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords