Building Hoist SC160 Contactor Scheider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

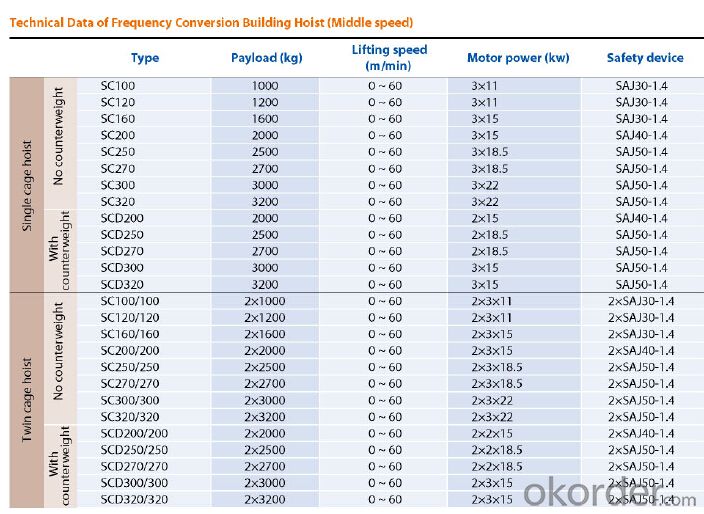

Payload(kg):1600

Lifting Speed(m/min):0~60

Motor Power(kw): 3*15

Safety Device: SAJ30-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC160

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

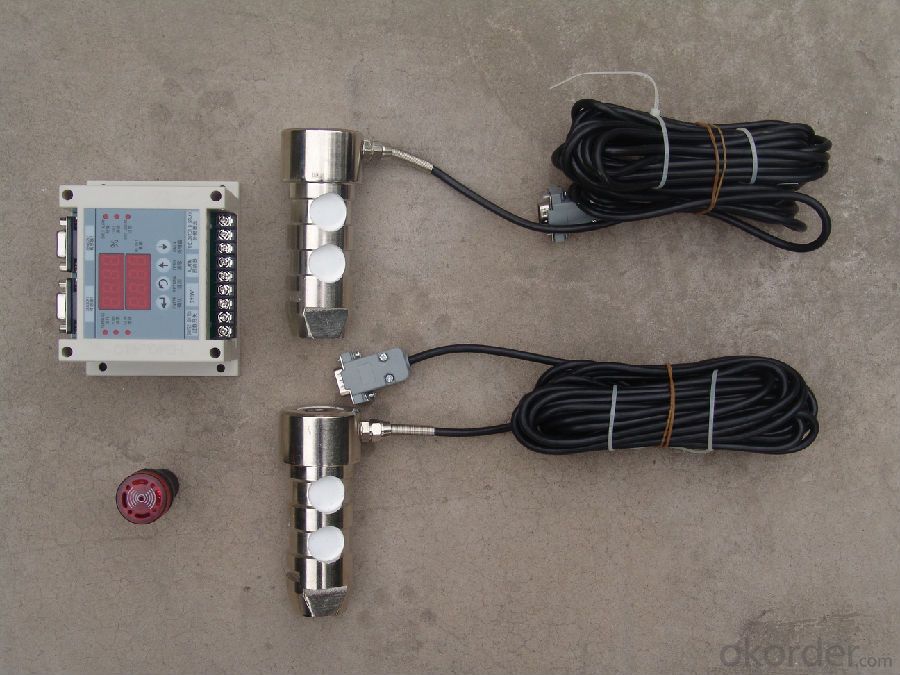

Building Hoist Images

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: This question asks for a description of the process of using an electric motor in the context of a building hoist, which is a device used for lifting and lowering materials in construction.

- <p>To use an electric motor with a building hoist, first ensure the hoist is properly installed and secured. Connect the hoist to a power source and check that all safety features are operational. Turn on the motor and test the hoist's movement in both directions to confirm functionality. When lifting materials, ensure they are evenly distributed and securely attached to the hoist. Operate the motor to lift or lower the load, maintaining a steady speed and monitoring for any signs of strain or malfunction. Always follow the manufacturer's guidelines and safety precautions to prevent accidents.</p>

- Q: Can a building hoist be utilized for the transportation of objects within and between buildings?

- <p>Yes, building hoists are specifically designed to move objects vertically within buildings. They are commonly used in construction to lift materials and equipment to different floors. Additionally, they can be employed to transport objects into and out of buildings, especially when access is limited or when heavy loads need to be moved over short vertical distances. However, it's important to adhere to safety guidelines and regulations when operating a building hoist to ensure the secure and efficient movement of objects.</p>

- Q: Is it possible to use a manual building hoist to lift multiple objects simultaneously?

- <p>Yes, a manual building hoist can be used to lift multiple objects at once, provided the total weight does not exceed the hoist's maximum load capacity. It's crucial to ensure that the hoist is securely attached to a stable structure and that all safety protocols are followed to prevent accidents. The objects should be evenly distributed and properly secured to the hoist to maintain balance and prevent tipping. Always refer to the manufacturer's guidelines for specific weight limits and safety instructions.</p>

- Q: This question asks about the measures taken to guarantee the safety and reliability of lifting equipment prior to its use in construction.

- <p>To ensure that lifting equipment is safe and reliable before using it in construction work, several key steps must be taken. Firstly, regular inspections and maintenance are crucial to identify any potential issues or wear and tear. Secondly, all equipment should be thoroughly tested and certified by qualified personnel to meet safety standards. Thirdly, proper training for operators is essential to ensure they understand how to use the equipment safely. Additionally, having a comprehensive safety plan in place, including emergency procedures, can help prevent accidents. Lastly, using equipment from reputable manufacturers and ensuring all components are in good working order are also vital for maintaining safety and reliability.</p>

- Q: There are two 18-story buildings under construction and tower cranes.

- In this case, you do not need to install the construction elevator at the main stage. After the main body is finished, install the tower crane, reinstall, mainly for decorate the vertical transport of the stage.

- Q: Is it possible to use a hydraulic cylinder as a substitute for the cylinder in a building hoist?

- <p>While it may be tempting to consider a hydraulic cylinder as a replacement for a building hoist cylinder, it is generally not advisable. Hydraulic cylinders and hoist cylinders serve different purposes and have distinct design specifications. A building hoist cylinder is specifically engineered to handle the vertical lifting and lowering of heavy loads in construction settings, ensuring safety and reliability. Hydraulic cylinders, on the other hand, are used for a variety of applications and may not meet the specific requirements of a hoist, such as load capacity, stroke length, or safety features. Using an inappropriate replacement could lead to mechanical failure, accidents, or even fatalities. It is crucial to use the correct, certified parts for any equipment to maintain safety and functionality.</p>

- Q: This question asks for guidance on selecting an appropriate building hoist, which is a type of lifting equipment used in construction.

- <p>Choosing a suitable building hoist involves considering several factors. First, assess the lifting capacity needed based on the weight of materials to be moved. Consider the hoist's speed and lifting height to ensure it meets project requirements. Evaluate the safety features, such as overload protection and emergency stop mechanisms. Check the hoist's durability and maintenance needs, as well as its compatibility with the building's structure. Consult with hoist manufacturers or rental companies for recommendations tailored to your specific project. Always prioritize safety and ensure the hoist complies with local regulations and standards.</p>

- Q: What is the highest weight a building hoist can safely lift?

- <p>The maximum load capacity of a building hoist can vary significantly depending on the specific model and design. Generally, capacities range from 500 kg to 3,000 kg or more. It's crucial to refer to the manufacturer's specifications for the exact load capacity of any given hoist. Overloading a hoist can lead to accidents and damage, so it's essential to operate within the specified limits.</p>

- Q: This question asks for the steps or methods to keep a building hoist in good condition and fix any damages.

- <p>To maintain and repair a damaged building hoist, follow these steps: Regularly inspect the hoist for wear and tear, checking cables, pulleys, and brackets. Lubricate moving parts to reduce friction and prevent rust. Replace damaged or worn-out components promptly. Ensure all safety features are functioning correctly. If a hoist is severely damaged, consult with a professional to assess the damage and perform necessary repairs. Always adhere to the manufacturer's guidelines and safety regulations during maintenance and repair processes.</p>

- Q: Is it possible to utilize a double-rope lifting mechanism within the context of a building hoist?

- <p>Yes, a double-rope lifting system can be used in a building hoist. This system offers advantages such as increased safety due to redundancy and the ability to lift heavier loads compared to a single-rope system. The double-rope setup allows for the hoist to handle the load with two separate ropes, reducing the risk of failure and providing a more stable lifting platform. It's common in applications where high load capacities and safety are paramount, such as in construction for lifting materials and equipment.</p>

Send your message to us

Building Hoist SC160 Contactor Scheider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords