Building Lifter SC160/160 Construction Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SC160/160 Building Lifter Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

3. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

4. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

5. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

6. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SC160/160 Building Lifter

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SC160/160 Building Lifter Specification

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Twin Cage Hoist | No Counterweight | SC100/100 | 2*1000 | 0~60 | 2*3*11 | 2*SAJ30-1.4 |

| SC120/120 | 2*1200 | 0~60 | 2*3*11 | 2*SAJ30-1.4 | ||

| SC160/160 | 2*1600 | 0~60 | 2*3*15 | 2*SAJ30-1.4 | ||

| SC200/200 | 2*2000 | 0~60 | 2*3*15 | 2*SAJ40-1.4 | ||

| SC250/250 | 2*2500 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC270/270 | 2*2700 | 0~60 | 2*3*18.5 | 2*SAJ50-1.4 | ||

| SC300/300 | 2*3000 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| SC320/320 | 2*3200 | 0~60 | 2*3*22 | 2*SAJ50-1.4 | ||

| With Counterweight | SCD200/200 | 2*2000 | 0~60 | 2*2*15 | 2*SAJ40-1.4 | |

| SCD250/250 | 2*2500 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD270/270 | 2*2700 | 0~60 | 2*2*18.5 | 2*SAJ50-1.4 | ||

| SCD300/300 | 2*3000 | 0~60 | 2*3*15 | 2*SAJ50-1.4 | ||

| SCD320/320 | 2*3200 | 0~60 | 2*3*15 | 2*SAJ50-1.2 |

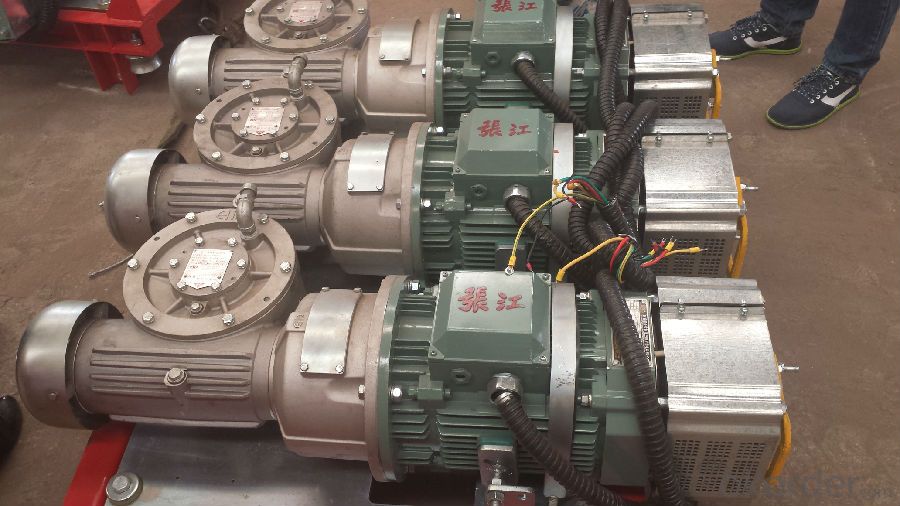

Images of SC160/160 Building Lifter

FAQ of SC160/160 Building Lifter

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of a building under construction. In commercial settings, they are often used in high-rise buildings, while in residential construction, they are used for multi-story homes or apartment complexes. However, the specific type and capacity of the hoist should be chosen based on the project's requirements and safety regulations must be strictly adhered to in both types of construction.</p>

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: This question asks about the measures to ensure that safety belts on a building hoist are correctly installed and utilized.

- <p>To ensure that safety belts on a building hoist are properly installed and used, follow these steps: 1. Regularly inspect the belts for any signs of wear, damage, or corrosion. 2. Ensure that the belts are securely fastened and properly adjusted according to the manufacturer's guidelines. 3. Conduct a thorough pre-use inspection before each operation to confirm that the belts are in good condition and functioning correctly. 4. Train all personnel on the proper use of safety belts and the importance of wearing them at all times while operating the hoist. 5. Implement a maintenance schedule to regularly check, clean, and lubricate the belts to prolong their lifespan and ensure optimal performance. 6. Replace any damaged belts immediately to prevent accidents and ensure the safety of workers.</p>

- Q: The difference between the derrick and the construction elevator?

- Derrick is with the hoist rope hoisting, referred to as goods for SSB100 type, with construction lifter model does not allow the manned, deadweight is one tons, construction lifter is said cargo amphibious ladder, with gear and rack driving, weight is 2 tons, you can have a look at the GB/T 10054-2005, the construction lifter, with clear rules.

- Q: How does the driver of the construction elevator do the search for a sudden power failure

- When the elevator in the operation of the midway stop due to power outages or other reasons, the manual can be decreased, the end of a motor brake electromagnet manual release slowly shake handshandle pull outward, slowly slide down the ladder cage, ladder cage fall shall not exceed the rated speed, manually drop must be conducted by professional maintenance personnel.

- Q: What steps are necessary to guarantee the safety and reliability of a building hoist?

- <p>To ensure a building hoist is safe and reliable for use, follow these steps: Conduct regular inspections and maintenance by qualified personnel. Check all mechanical and electrical components for wear and tear. Ensure all safety features, such as emergency stop buttons and limit switches, are functioning correctly. Verify that the hoist is properly secured to the building and that all load-bearing elements are capable of handling the weight. Adhere to the manufacturer's guidelines and specifications for operation. Train operators on the proper use of the hoist and emergency procedures. Regularly test the hoist's load capacity and stability. Keep records of all inspections, maintenance, and any incidents for future reference.</p>

- Q: The user is asking if it's possible to use a building hoist, typically used for construction, to lift a car.

- <p>Using a building hoist to lift a car is not recommended. Building hoists are designed for lifting materials and equipment in construction settings, not for vehicles. They may not have the appropriate safety features or load-bearing capacity for a car. Attempting to lift a car with a building hoist could result in damage to the car, the hoist, or even personal injury. For lifting a car, it's best to use a vehicle-specific lift or a hydraulic lift designed for such purposes, ensuring safety and proper support.</p>

- Q: This question asks for the steps or process involved in installing a building hoist, which is a type of crane used in construction to lift materials.

- <p>Installing a building hoist involves several steps: 1) Site preparation, ensuring the ground is level and strong enough to support the hoist. 2) Assembling the hoist tower, starting from the base and working upwards. 3) Installing the motor and drive system. 4) Attaching the cable and counterweight. 5) Rigging the hoist with safety devices and load limiters. 6) Conducting a thorough inspection and testing the hoist for safety and functionality. 7) Obtaining any necessary permits and approvals. It's crucial to follow the manufacturer's instructions and local regulations, and often requires a professional team for safe and proper installation.</p>

- Q: Where is the location of the elevator in the project

- The position of construction elevator is usually set in the project to facilitate access to material, material handling and personnel up and down, not affecting the construction process.

- Q: What is the highest weight a building hoist can safely lift?

- <p>The maximum load capacity of a building hoist can vary significantly depending on the specific model and design. Generally, capacities range from 500 kg to 3,000 kg or more. It's crucial to refer to the manufacturer's specifications for the exact load capacity of any given hoist. Overloading a hoist can lead to accidents and damage, so it's essential to operate within the specified limits.</p>

Send your message to us

Building Lifter SC160/160 Construction Hoist

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords