Building Hoist SC200 Relay Schneider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

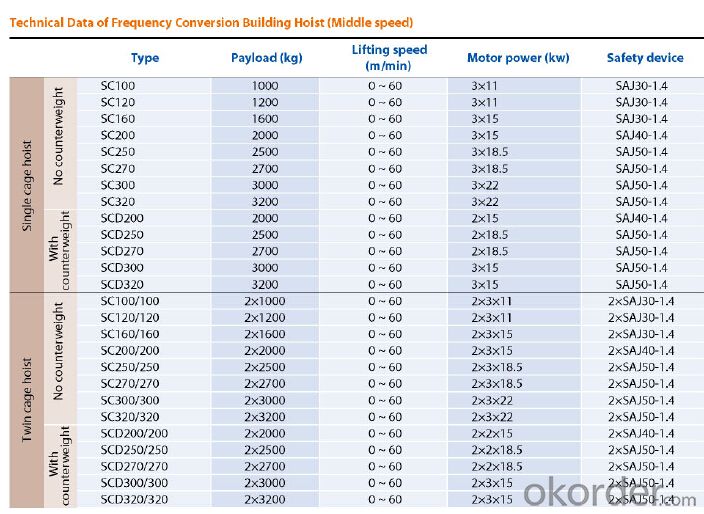

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):2000

Lifting Speed(m/min):0~60

Motor Power(kw): 3*15

Safety Device: SAJ40-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC200

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

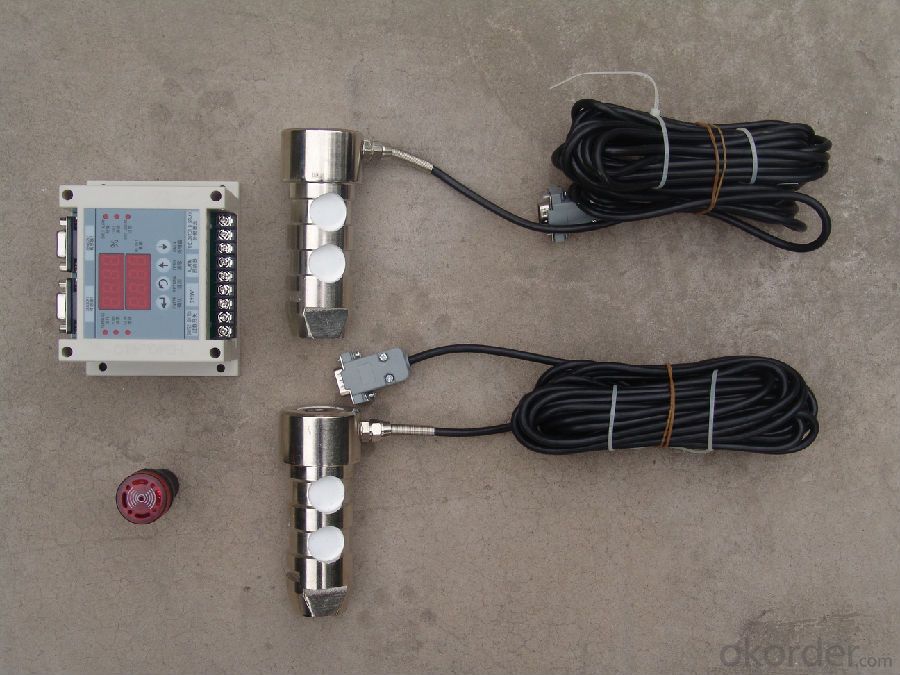

Building Hoist Images

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Safe use of construction elevator

- In the case of passenger and carriage, the loading shall be uniformly distributed, and the overload shall be strictly prohibited. When the elevator runs to the top and lowest levels, it is strictly forbidden to stop at the collision or lower limit. 7. The driver for leaving hanging basket and while going off work, should be hanging basket fell to the ground, to cut off the total power supply, and the door is locked point, prevent other undocumented workers start the hoisting cage without authorization. Wind up above 6, should stop using the elevator and bring the cage down to the ground. There must be good protection on both sides of the transportation channel. Floor door should be in a normally closed state, its height should conform to the requirements of the specification, anyone shall not open or head out of the door, when the floor door open, the driver shall not start the elevator. Ensure that the communication device is in good condition and the driver should be able to start the lift after confirming the signal. The driver should immediately execute any emergency stop signal on the floor of the operation. The elevator should be installed on a separate ground protection and lightning protection device. It is strictly forbidden to do maintenance work under the condition of the elevator. If maintenance is required, the power supply must be cut off and the sign of "check in, shut off" will be hung in a prominent place.

- Q: This question asks for the distinctions between two types of construction equipment: a building hoist and a lifting platform.

- <p>A building hoist, also known as a construction hoist, is a temporary elevator used in the construction of high-rise buildings to transport workers, materials, and equipment up and down the building. It is typically installed on the exterior of the building and is designed for vertical transportation. On the other hand, a lifting platform is a type of aerial work platform that can be either mobile or stationary and is used to lift workers and tools to a specific height for maintenance, repair, or construction tasks. Lifting platforms are often used for outdoor tasks and can be mobile, allowing them to be moved around a worksite as needed. The main difference lies in their application: building hoists are for vertical transport within a structure, while lifting platforms provide height access for a variety of tasks.</p>

- Q: Is it safe to use a building hoist for lifting heavy objects when there is wind?

- <p>Using a building hoist in windy weather is generally not recommended due to the increased risk of accidents. Wind can cause the hoist to sway, potentially leading to loss of control and dropping of the load. Safety guidelines typically advise against hoisting operations when wind speeds exceed certain limits, often around 20-30 miles per hour (32-48 kilometers per hour). It's crucial to check local regulations and the manufacturer's guidelines for the specific hoist model to determine safe operating conditions. Always prioritize safety and ensure that all necessary precautions are taken to secure the load and the hoist in windy conditions.</p>

- Q: Is it possible to use a lifting device to assist in lifting a person who is too heavy to lift manually?

- <p>Yes, lifting devices such as hoists or mechanical lifts can be used to safely lift someone who is too heavy to lift manually. These devices are designed to support the weight and reduce the risk of injury to both the person being lifted and the caregiver. It's important to use the appropriate equipment for the individual's weight and to follow safety guidelines and manufacturer's instructions to ensure proper and secure lifting.</p>

- Q: This question seeks to understand the various types of electric lifting equipment utilized in the construction industry.

- <p>In the construction industry, various types of electric lifting equipment are used to facilitate the movement of heavy materials and equipment. Some of the common types include: 1. Electric Hoists: These are used for vertical lifting and lowering of loads. 2. Electric Cranes: They are mobile lifting machines with a long boom and can move loads horizontally and vertically. 3. Electric Forklifts: They are used for lifting and transporting heavy loads in a warehouse or construction site. 4. Electric Scissor Lifts: These are mobile platforms that can be raised to allow workers to reach high areas. 5. Electric Stackers: Used for stacking and unstacking materials in a warehouse. 6. Electric Pallet Trucks: These are used for moving heavy pallets of materials. Each type of equipment serves a specific purpose and is chosen based on the requirements of the construction project.</p>

- Q: Is it possible to utilize a building hoist for the purpose of moving materials up and down in a warehouse setting?

- <p>Yes, a building hoist can be used to lift and lower materials in warehouses. These hoists are designed for vertical transportation of goods and are particularly useful in multi-story warehouses where space is limited. They are capable of handling heavy loads and can be operated manually or with electric power, making them efficient for moving materials between different levels of a warehouse. However, safety measures and proper maintenance are crucial to ensure the secure and effective operation of the hoist.</p>

- Q: Is it possible for a building hoist to lift more than one object simultaneously?

- <p>Yes, a building hoist can lift multiple objects at once, provided the combined weight does not exceed the hoist's maximum load capacity. The hoist's design and specifications will dictate how many and what types of objects can be lifted simultaneously. It's crucial to follow the manufacturer's guidelines to ensure safety and prevent damage to the hoist or the objects being lifted.</p>

- Q: This question asks for a comparison of the pros and cons associated with the use of building hoists in construction projects.

- <p>Building hoists offer several advantages, including increased efficiency in material transportation, reduced labor costs, and improved safety by minimizing the need for manual handling at height. They can also be used for personnel transport, enhancing site accessibility. However, there are disadvantages such as high initial costs, the need for regular maintenance and inspection, and potential downtime due to mechanical issues. Additionally, they require space for installation and can obstruct views or access during operation. Safety concerns also arise if not properly managed, as accidents can occur due to operator error or mechanical failure.</p>

- Q: This question asks if improper functioning or lack of maintenance in hydraulic cylinders can lead to damage.

- <p>Yes, hydraulic cylinders can cause significant damage if they malfunction or are not properly maintained. Malfunctions can lead to leaks, component failure, or even structural damage due to pressure surges. Lack of maintenance can cause wear and tear, leading to reduced efficiency and potential failure. Regular maintenance, including checking for leaks, ensuring proper lubrication, and replacing worn parts, is crucial to prevent damage and ensure the safe operation of hydraulic systems.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

Send your message to us

Building Hoist SC200 Relay Schneider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords