Building Hoist SC120 Spare Parts Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

The general building hoist manufactured by our company have the features as good quality, long life, wide application range and convenient for maintenance. The gearing adopted bearing,enameled cable, and oil seal. The electric parts adopt products from worl renowned manufacturers such as Schneider, Siemes, and LG. The racks and pinion adopts specal material and heat-treatment technique, which prolong the life of these parts. The steel structure uses quality steel from famous domestic manufacturers. The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminum board.

Main Features of Building Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing..

Building Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 33 | 2*11 | SAJ30-1.2 |

| SC120 | 1200 | 33 | 2*11 | SAJ30-1.2 | ||

| SC160 | 1600 | 33 | 2*11 | SAJ30-1.2 | ||

| SC200 | 2000 | 33 | 3*11 | SAJ40-1.2 | ||

| SC250 | 2500 | 33 | 3*11 | SAJ50-1.2 | ||

| SC270 | 2700 | 33 | 3*15 | SAJ50-1.2 | ||

| SC300 | 3000 | 33 | 3*15 | SAJ50-1.2 | ||

| SC320 | 3200 | 33 | 3*15 | SAJ50-1.2 | ||

| With Counterweight | SCD200 | 2000 | 33 | 2*11 | SAJ40-1.2 | |

| SCD250 | 2500 | 33 | 2*11 | SAJ50-1.2 | ||

| SCD270 | 2700 | 33 | 2*15 | SAJ50-1.2 | ||

| SCD300 | 3000 | 33 | 2*15 | SAJ50-1.2 | ||

| SCD320 | 3200 | 33 | 2*15 | SAJ50-1.2 |

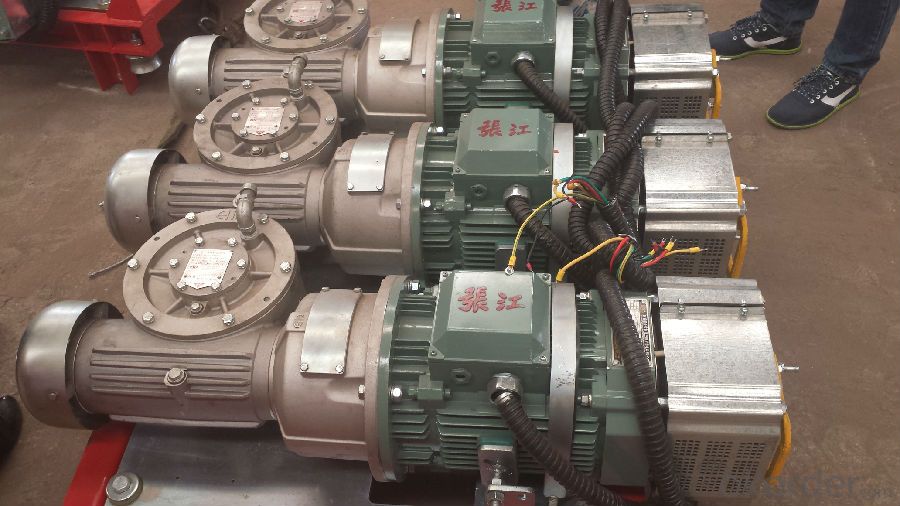

Images of Building Hoist

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for steps to ensure that lifting equipment is safe and reliable before it is used.

- <p>To ensure your lifting equipment is safe and reliable before use, follow these steps: Inspect the equipment for any visible damage or wear. Check all safety features such as hooks, cables, and brakes. Ensure that the equipment is properly maintained and serviced according to the manufacturer's guidelines. Verify that all safety certifications and inspection records are up to date. Conduct a thorough pre-use check, including testing the equipment's lifting capacity and stability. Ensure that all operators are trained and certified to use the equipment. Never use equipment that has not been inspected or is showing signs of damage. Always follow the manufacturer's guidelines and safety protocols.</p>

- Q: This question seeks to understand the distinctions among various types of building hoists, which are essential in construction for lifting materials.

- <p>Building hoists, also known as construction hoists, are crucial for transporting materials and personnel in construction projects. The main types include: 1) Goods Hoists, designed for lifting materials and equipment, often with a higher load capacity. 2) Personnel Hoists, specifically for workers, prioritize safety features. 3) Material Hoists, a combination of goods and personnel hoists, allowing both material transport and worker movement. 4) Electric Chain Hoists, powered by electricity, known for their efficiency and control. 5) Manual Chain Hoists, requiring manual operation, useful in areas with no power supply. 6) Electric Winch Hoists, offering high lifting speeds and capacities. Each type varies in capacity, speed, control mechanisms, and power source, impacting their suitability for specific construction needs.</p>

- Q: A building hoist is a piece of equipment used in construction to lift materials and personnel.

- <p>A building hoist, also known as a construction hoist or material hoist, is a temporary lifting device used in the construction industry to transport materials, equipment, and sometimes personnel vertically within a building under construction. It is essential for efficient movement of heavy and bulky items, reducing manual labor and improving safety by minimizing the need for workers to climb ladders or handle heavy loads manually. These hoists are typically installed on the exterior of the building and are used throughout the construction process until the building's permanent elevators are installed and operational.</p>

- Q: This question asks for safety guidelines and procedures to be followed when operating a building hoist.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is regularly inspected and maintained by qualified personnel. Never exceed the hoist's load capacity. Keep the hoist and its surroundings clean and free from debris. Always use safety hooks and never leave the hoist unattended when in use. Ensure all safety features, such as limit switches and emergency stop buttons, are functioning correctly. Train operators on the proper use of the hoist and adhere to all manufacturer's instructions. Never use a hoist if it shows signs of damage or malfunction. Always wear appropriate personal protective equipment (PPE) when operating a hoist.</p>

- Q: How many meters or how many layers should the construction elevator be installed?

- Construction elevator is also called construction lifter, alias outdoor elevator or people dual-purpose ladder. The country is not clear how many meters or how many layer must be used, but in some coastal developed cities are now more than 30 meters using construction elevator, some cities also issued relevant rules more than 30 meters must use construction lifter, gantry and hoist is no longer used.

- Q: Is it possible for a single lifting device to simultaneously lift multiple objects with varying weights?

- <p>Yes, a single lifting device can be used to lift multiple objects at once with different weights, provided the total weight does not exceed the device's lifting capacity. The device must be designed to handle the combined weight and ensure even distribution of the load. Safety measures and proper securing of the objects are crucial to prevent accidents. It's important to follow the manufacturer's guidelines and never exceed the maximum load capacity to avoid damage or injury.</p>

- Q: How many people are there for construction workers

- At the end of the 20th century, the elevator was powered by the permanent magnet synchronous towing machine. It greatly reduces the space of the machine room, and it has the advantages of low energy consumption, energy efficiency and speed, which has greatly contributed to the development of real estate. Thyssenkrupp elevator company has developed a new type of "multiple lift" that can operate vertically. Take the size of a common car The size of the escalator is quite different: but the total area is required in the national standard. Give you a general calculation The width of the well is the width of the car. Well, the depth of the well = the car depth + 600 (for the reside) The width of the well is the width of the car. Well, the depth of the well = the car's depth + 1200 (for the rear-end). The u-shaped tourist ladder is usually around 1000kg The car is usually about 1300x1800 The steel structure shaft is width between 2200 and 2400, depending on the size of the door. The depth of the structure is about 1500, and the rear wall is empty.

- Q: Is it possible to use a lifting device to lift objects that are heavier than its specified maximum load?

- <p>No, a lifting device should never be used to lift objects that exceed its rated load capacity. Doing so can lead to catastrophic failure of the device, potentially causing serious injury or death. Always adhere to the manufacturer's specifications to ensure safety and prevent accidents. Overloading a lifting device can result in structural damage, compromised safety mechanisms, and increased risk of collapse or dropping the load. It is crucial to respect the load limits to maintain the integrity and reliability of the lifting equipment.</p>

- Q: How large a leakage protector is used for the construction elevator

- A leakage switch with a rated current of 100-160a. The rated action current of the second class is 50-75hm. The rated action current is 30-45hm. The action time is less than or equal to 0.1 s. Comply with safety specification according to this construction.

- Q: Is it possible to replace a lifting rope in a construction hoist with a regular rope?

- <p>No, a regular rope should not be used as a substitute for a lifting rope in a building hoist. Lifting ropes are specifically designed for heavy-duty lifting and have safety standards to ensure they can withstand the weight and stress. Regular ropes lack these safety features and can break under heavy loads, leading to accidents. Always use the appropriate lifting equipment as specified by safety regulations and the manufacturer's guidelines.</p>

Send your message to us

Building Hoist SC120 Spare Parts Manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords