Building Hoist SC200 Lifting Machines Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Building Hoist SC200 Lifting Machines Supplier

The hoist adopted with the normal electrical control method, is equipped with contactor, control transformer, anti-overheat protector, relay against the phase failure & disorder. All the electrical parts are equipped with Schneider and Siemens products.

The inverter, as a key controlling part, is used in the hoist adopted with VFD+PLC control method. This device is jointly developed by Japan Yaskawa and us. The hardware is supplied by Yaskawa, while the controlling software is supplied by us ensuring safe & reliable operations. PLC controller adopts OMROM products; brake unit is from YASKAWA and other electrical components are from Schneider or Siemens.

With application of VFD, it’s able to realize stepless speed regulating between zero and max speed. There are two shifting-gears set in the operating platform. One is maintenance shift, which can enable the cage run at speed of 0~5M/min for user to check the lubricating condition and connection of the machine’s parts. The other is working shift, enabling the cage with normal working speed. By adopting this control method, it’s also able to check and show the condition of power supply, operation and electrical failure. Moreover, it can avoid misoperation, giving great protection to transmission & electrical system.

Main Parts of Building Hoist

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

7. The system applies the special software for hoists developed by our company, making the operation more safe and reliable.

Building Hoist images

CMAX Building Hoist

Anchorage System

Driving Unit

Warehouse

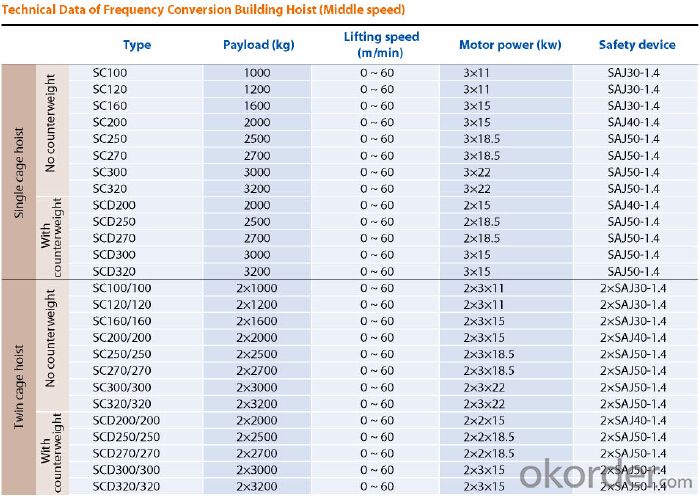

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance & exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: How does the driver of the construction elevator do the search for a sudden power failure

- There are clear rules for the safety of construction machinery (JGJ33-2001). 6.12.17 when the elevator is running in an existing abnormal condition, it should stop immediately and take effective measures to reduce the cage down to the ground level, and keep running after the failure. When the electric is out of control in operation, the stop button should be pressed immediately. The stop button is not allowed until the failure is ruled out. 6.12.20 when elevator in the operation of the midway stop due to power outages or other reasons, can be manually, the end of a motor brake electromagnet manual release slowly shake handshandle pull outward, slowly slide down the ladder cage, ladder cage fall shall not exceed the rated speed, manually drop must be conducted by professional maintenance personnel manipulation.

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: This question asks whether a building hoist can be utilized in construction or demolition activities.

- <p>Yes, a building hoist can be used for both construction and demolition work. In construction, hoists are essential for transporting materials and personnel vertically within a building under construction. They are designed to handle heavy loads and operate safely at significant heights. In demolition, hoists can be used to remove debris and transport workers to different levels of a structure being dismantled. However, it's crucial to ensure that the hoist is suitable for the specific task and that all safety protocols are followed to prevent accidents.</p>

- Q: What are the key safety rules and regulations that must be followed when operating a building hoist?

- <p>Safety regulations for using a building hoist include ensuring that the hoist is inspected and certified by a qualified person before use. Operators must be trained and certified. The hoist should be used only for its intended purpose, and load limits must never be exceeded. Regular maintenance and checks are required to ensure the hoist remains in good working order. Safety devices such as limit switches and emergency stops must be operational. The hoist area should be kept clear of obstructions, and warning signs should be posted. Personal protective equipment (PPE) must be worn by operators and anyone in the vicinity. Overhead protection should be provided to prevent objects from falling onto the hoist. Compliance with local and national regulations is also crucial.</p>

- Q: This question asks whether a double-rope lifting system can be safely and effectively used in both indoor and outdoor environments, specifically during windy conditions.

- <p>A double-rope lifting system can be used both indoors and outdoors, but its use in windy conditions requires careful consideration. Indoors, it is generally safe and effective. Outdoors, windy conditions can pose challenges. High winds may cause the load to sway, potentially leading to accidents. Therefore, it's crucial to adhere to safety guidelines, which often recommend not using such systems in winds exceeding certain speeds, typically around 20-30 mph. Always check the manufacturer's specifications and local regulations for safe operating conditions.</p>

- Q: Identify the elements that influence the durability and operational lifespan of lifting machinery, specifically focusing on Building Hoists.

- <p>The lifespan of lifting equipment, including Building Hoists, is influenced by several factors: 1) Material Quality: The type and quality of materials used in construction directly affect durability and resistance to wear and tear. 2) Design and Engineering: Proper design ensures optimal performance and reduces stress on components. 3) Frequency of Use: More frequent use can lead to faster wear and tear. 4) Maintenance and Repair: Regular maintenance can extend the lifespan, while neglect can shorten it. 5) Operating Conditions: Environmental factors such as temperature, humidity, and exposure to corrosive substances can impact longevity. 6) Load Capacity: Overloading can cause premature failure. 7) Compliance with Safety Standards: Adhering to safety guidelines can prevent accidents and damage. 8) Technological Advancements: Newer models may have improved features that extend lifespan.</p>

- Q: How to adjust the weight limit of the construction elevator

- You're not going to be without a master You still look at the instructions

- Q: This question asks if building hoists can be utilized both indoors and outdoors, and if they can operate under windy or rainy weather conditions.

- <p>Building hoists can be used both indoors and outdoors, but their operation in windy or rainy conditions depends on specific safety guidelines and the hoist's design. Outdoor hoists must be designed to withstand weather conditions and should be equipped with weatherproof covers to protect against rain and wind. In windy conditions, hoists may have operational limits based on wind speed to ensure safety. It's crucial to follow the manufacturer's guidelines and local regulations regarding weather conditions to prevent accidents and ensure the hoist's safe operation.</p>

- Q: This question asks about the time required to install a building hoist, a device used for lifting materials in construction.

- <p>The time it takes to install a building hoist can vary significantly based on factors such as the type and size of the hoist, the specific building requirements, and the experience of the installation team. On average, it can take anywhere from a few hours to a couple of days. For smaller hoists, installation might be completed within a day, while larger, more complex systems could take longer. It's important to note that safety checks and regulatory compliance verifications are also part of the process, which can add to the total installation time.</p>

- Q: Is it possible to use a building hoist to lift various types of materials?

- <p>Yes, a building hoist can be used for lifting different materials. It is designed to handle a wide range of loads, from construction materials like bricks and cement to heavy equipment. However, it is crucial to ensure that the materials being lifted are within the hoist's weight capacity and that they are properly secured to prevent accidents. Always follow the manufacturer's guidelines and safety regulations when using a building hoist to lift various materials.</p>

Send your message to us

Building Hoist SC200 Lifting Machines Supplier

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords