Building Hoist SC120/120 Frequency Conversion Twin Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2*1200 Lifting Speed(m/min):0~60 Motor Power(kw): 2*3*11

Safety Device: 2*SAJ30-1.4 Cage: Twin Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SC120/SC120

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Building Hoist Images

CMAX Building Hoist

Limiter

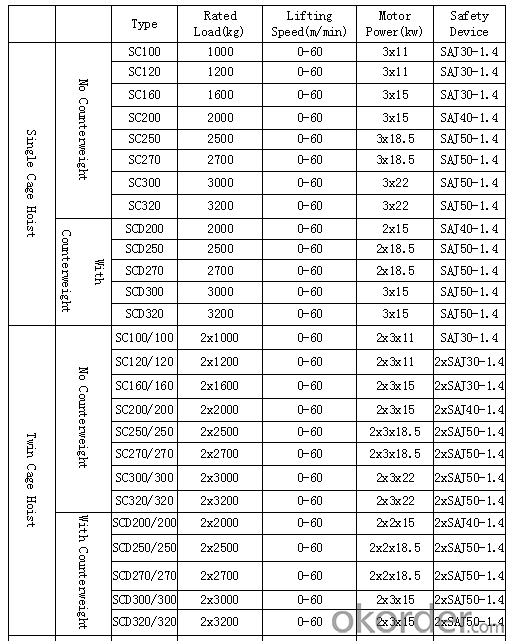

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: Is it possible to use a single automatic building hoist to lift multiple objects simultaneously?

- <p>Yes, an automatic building hoist can be used to lift multiple objects at once, provided that the combined weight of the objects does not exceed the hoist's maximum load capacity. It is crucial to ensure that the hoist is designed for such operations and that all safety precautions are taken to prevent overloading, which can lead to accidents. The hoist should be equipped with a load limiter to automatically cut off power if the load exceeds safe limits, ensuring the safety of the operation.</p>

- Q: This question asks about the methods to ensure that lifting equipment is correctly positioned and functioning during its operation.

- <p>To ensure that lifting equipment is properly aligned during operation, follow these steps: 1. Conduct a thorough inspection before use, checking for any visible damage or misalignment. 2. Use precision measuring tools to verify the alignment of the equipment's components. 3. Adhere to the manufacturer's guidelines and specifications for alignment. 4. Regularly calibrate the equipment to maintain accuracy. 5. Train operators on proper alignment procedures and safety protocols. 6. Implement a maintenance schedule to address any alignment issues promptly. 7. Use load testing to confirm that the equipment can handle the intended load without misalignment. Proper alignment is crucial for safety and efficiency in lifting operations.</p>

- Q: This question asks for the cost associated with purchasing and installing a building hoist.

- <p>The cost of buying and installing a building hoist can vary significantly depending on several factors. The type and capacity of the hoist, the height of the building, and the complexity of the installation are key determinants. On average, the cost can range from $10,000 to $50,000 for the hoist itself, with installation costs potentially adding another 20-50% to the total. However, for very tall buildings or specialized hoists, the price can exceed $100,000. It's crucial to obtain quotes from multiple suppliers and installers to get an accurate estimate for your specific project.</p>

- Q: This question asks for measures to protect lifting equipment from damage during its operation.

- <p>To prevent damage to lifting equipment during operation, ensure regular maintenance and inspection are conducted to check for wear and tear. Adhere to the equipment's load limits and never exceed them. Use appropriate lifting techniques and ensure the load is balanced. Keep the equipment clean and free from debris. Train operators thoroughly on safe operating procedures. Avoid sudden starts or stops, and ensure all safety features and guards are in place and functioning correctly. Regularly check cables, hooks, and other critical components for any signs of damage. Always follow the manufacturer's guidelines and industry safety standards.</p>

- Q: Is it possible to utilize a building hoist for the purpose of lifting heavy objects or construction materials?

- <p>Yes, a building hoist is specifically designed for lifting large objects and materials in construction settings. These hoists are engineered to handle heavy loads, making them ideal for transporting construction materials, equipment, and other heavy items vertically within a building. They are equipped with safety features and are regulated to ensure they can bear the weight and pressure of the materials being lifted, thus playing a crucial role in the construction process.</p>

- Q: This question asks about the different types of hydraulic cylinders that are utilized in lifting equipment.

- <p>Hydraulic cylinders used in lifting equipment can be categorized into several types based on their design and application. The main types include: single-acting cylinders, which have one port for fluid and rely on the load or a spring to return; double-acting cylinders, which have ports on both ends and can extend and retract through fluid pressure; telescopic cylinders, which consist of multiple stages that can extend sequentially for greater reach; and rotary hydraulic cylinders, which provide a combination of linear and rotary motion. Each type is chosen based on the specific requirements of the lifting task, such as the need for speed, force, and control.</p>

- Q: This question asks for an explanation of the different types of building hoists used in construction.

- <p>Building hoists, also known as construction hoists or material hoists, are essential for moving materials and personnel in high-rise construction projects. The main types include: 1. <strong>Freestanding Hoists</strong>: These do not require a building structure for support and are self-supporting. 2. <strong>Cladding Hoists</strong>: Attached to the building's facade, used for moving materials during cladding work. 3. <strong>Personnel Hoists</strong>: Specifically designed for transporting workers, ensuring safety with features like cages and safety devices. 4. <strong>Material Hoists</strong>: Built to transport heavy construction materials and are robust and durable. 5. <strong>Electric Hoists</strong>: Operated by electricity, offering precise control and energy efficiency. 6. <strong>Hydraulic Hoists</strong>: Utilize hydraulic systems for lifting, known for their smooth operation and heavy load capacity. Each type serves a specific purpose and is chosen based on the project's requirements and the stage of construction.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

- Q: What is the capability of a building hoist in terms of lifting large objects?

- <p>Yes, building hoists are designed to lift and transport large objects in construction settings. They have a high load capacity, often ranging from several hundred to several thousand kilograms, depending on the model and specifications. Building hoists are equipped with safety features to ensure secure lifting and are commonly used for moving materials such as cement, bricks, and heavy equipment within multi-story buildings under construction. However, it's crucial to adhere to the manufacturer's guidelines regarding weight limits and safety protocols to prevent accidents.</p>

Send your message to us

Building Hoist SC120/120 Frequency Conversion Twin Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords