Buidling Construction Hoist CMAX Brand for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

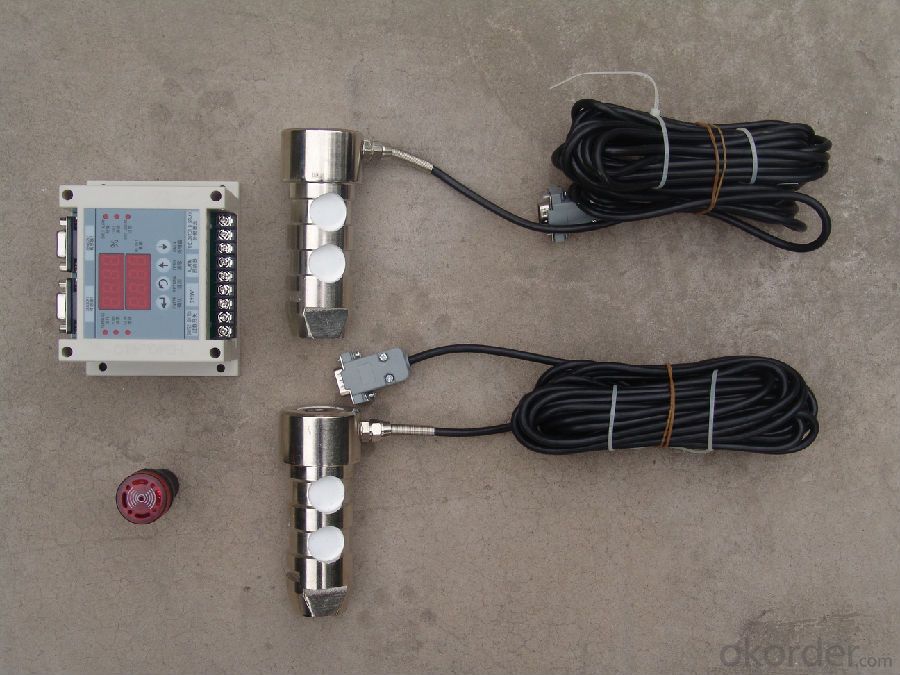

Building Hoist Images

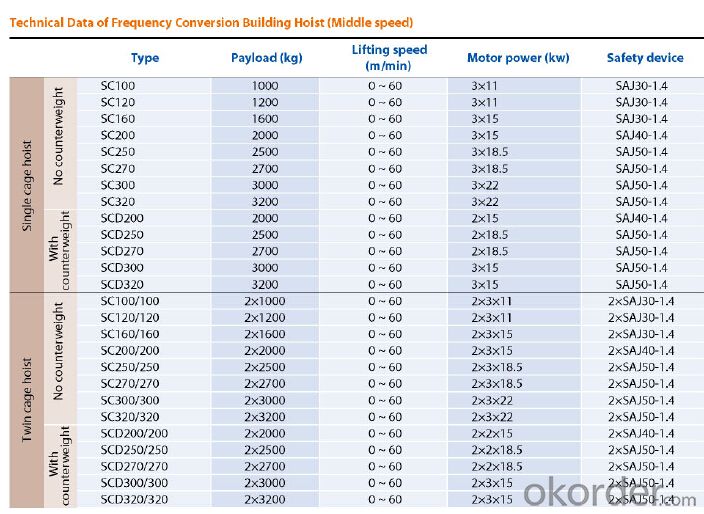

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Explain the distinctions between electric and manual building hoists, focusing on their operation, efficiency, and use cases.

- <p>Electric building hoists are powered by electricity and offer faster operation, greater efficiency, and the ability to lift heavier loads. They are ideal for large-scale construction projects where rapid movement of materials is necessary. In contrast, manual hoists are operated by hand and are typically smaller, more portable, and require human effort to lift materials. They are suitable for smaller projects or where power supply is limited. Electric hoists are more automated and can be controlled remotely, while manual hoists require constant physical effort and are less efficient in terms of speed and load capacity.</p>

- Q: Is it possible to use a building hoist for lifting fragile or delicate items?

- <p>A building hoist is generally designed for heavy construction materials and not for delicate objects. However, with the right attachments and careful operation, it can be adapted for lifting delicate items. It's crucial to ensure the hoist is equipped with appropriate stabilizers and cushioning to prevent damage. Always follow safety guidelines and consult with the manufacturer or a professional to determine if the hoist can be safely used for such purposes.</p>

- Q: Is it possible to utilize a building hoist for the purposes of renovation projects?

- <p>Yes, a building hoist can be used for renovation work. These hoists are designed to lift and lower materials and personnel efficiently, making them ideal for construction and renovation projects. They help in moving heavy materials such as bricks, cement, and tools to different floors without the need for manual labor, thus increasing safety and productivity. However, it's crucial to ensure that the hoist is properly installed, maintained, and operated by trained personnel to avoid accidents and ensure the safety of all involved.</p>

- Q: This question asks for a comparison of various types of electric building hoists, highlighting their unique features and differences.

- <p>Electric building hoists come in various types, each designed for specific applications. The main differences lie in their capacity, lifting speed, control systems, and construction. For instance, worm gear hoists are compact and offer precise control, suitable for light to medium-duty applications. Chain hoists are versatile with higher speeds and are ideal for general lifting tasks. Electric wire rope hoists are powerful and designed for heavy-duty lifting, often used in construction and industrial settings. Variable frequency drives in hoists allow for speed control, enhancing safety and efficiency. Each type has its operational advantages and limitations, making the choice dependent on the specific lifting requirements and environmental conditions.</p>

- Q: This question asks for the steps or methods to fix a building hoist that is not working properly.

- <p>To repair a malfunctioning building hoist, first, ensure the hoist is powered off and disconnected from any power source to ensure safety. Inspect the hoist for visible damage or loose parts. Check the motor, cables, and control panel for any signs of wear or damage. If the issue is mechanical, such as a stuck cable or a jammed pulley, disassemble the affected parts and clean or replace them as necessary. For electrical issues, inspect the wiring and connections for any shorts or breaks. Consult the hoist's manual for troubleshooting guides specific to the model. If the problem persists or if you're unsure about any steps, it's best to contact a professional technician for repair to avoid further damage or safety hazards.</p>

- Q: This question asks whether it is safe to operate a building hoist in adverse weather conditions such as wind and rain.

- <p>The use of a building hoist in windy or rainy weather is generally not recommended due to safety concerns. Wind can cause instability and swaying of the hoist, while rain can lead to slippery conditions and electrical hazards. Most hoist manufacturers and safety guidelines advise against operating hoists in such conditions. However, if absolutely necessary, it should be done with extreme caution, following specific safety protocols, and ensuring all necessary weatherproofing and stability measures are in place. Always consult the manufacturer's guidelines and local regulations before operating a hoist in adverse weather.</p>

- Q: How large a leakage protector is used for the construction elevator

- A leakage switch with a rated current of 100-160a. The rated action current of the second class is 50-75hm. The rated action current is 30-45hm. The action time is less than or equal to 0.1 s. Comply with safety specification according to this construction.

- Q: This question asks for an explanation on how to operate an automatic control system for a building hoist.

- <p>To use an automatic control system for a building hoist, first ensure the system is properly installed and inspected. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Ensure all safety protocols are in place. Turn on the system and select the desired hoist. Use the up and down buttons to control the hoist's movement. Monitor the load and adjust the speed as needed. Always be aware of the hoist's limits and never exceed them. Regularly check the system for any faults or irregularities and address them promptly. Remember, safety is paramount when operating a building hoist.</p>

- Q: This question asks for guidance on selecting appropriate lifting equipment based on specific requirements and work conditions.

- <p>To choose the right type of lifting equipment for your specific needs and work environment, consider the following: 1. Load capacity: Ensure the equipment can handle the weight of the items you need to lift. 2. Workspace: Evaluate the size and layout of your work area to determine the appropriate size and type of equipment. 3. Safety features: Look for equipment with safety features that meet your industry's standards. 4. Mobility: Consider whether you need a mobile or stationary unit. 5. Compatibility: Ensure the equipment is compatible with other tools or machinery you use. 6. Budget: Determine your budget and find equipment that offers the best value for your investment. 7. Consult with experts: Speak with equipment manufacturers or distributors to get their recommendations based on your specific needs. Always prioritize safety and efficiency when selecting lifting equipment.</p>

- Q: What is the purpose of a building hoist and can it be utilized for lifting heavy objects that cannot be manually lifted?

- <p>Yes, building hoists are specifically designed to lift heavy objects that are beyond the capacity of manual lifting. They are essential in construction sites for moving materials such as bricks, cement, and steel beams to various levels of a building. Building hoists are engineered to handle significant weight and ensure the safe and efficient transport of materials, reducing the risk of injury and improving productivity on construction sites.</p>

Send your message to us

Buidling Construction Hoist CMAX Brand for Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords