Buidling Hoist Construction Lifter CMAX Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

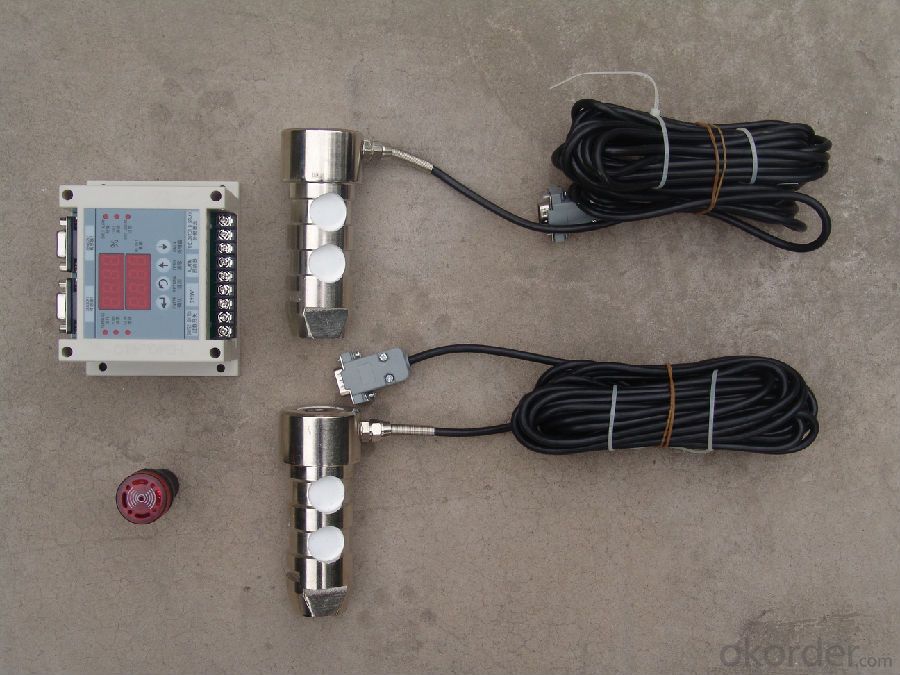

Building Hoist Images

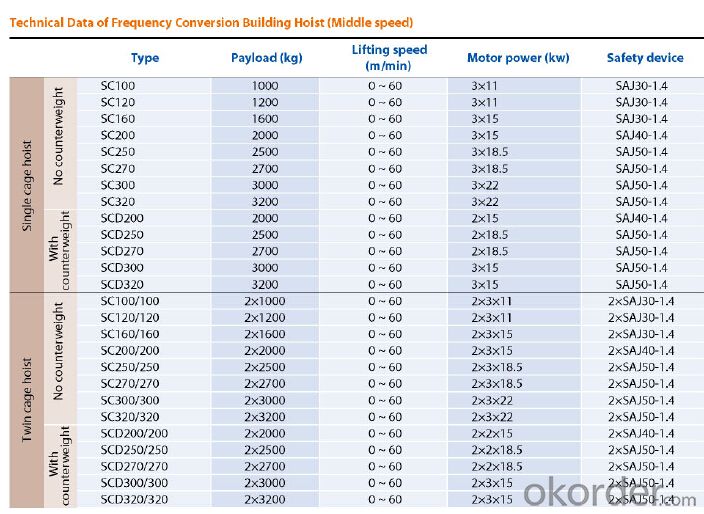

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Describe the routine maintenance and inspection procedures for a building hoist.

- <p>The maintenance and inspection process for a building hoist involves several key steps to ensure safety and functionality. Regular visual inspections should be conducted to check for any visible damage or wear. Monthly inspections should include testing the emergency stop and limit switches, as well as lubricating moving parts. Quarterly inspections may involve checking the electrical connections and verifying the correct operation of safety devices. Annual inspections typically require a thorough examination by a qualified person, including testing the load-bearing capacity and ensuring all safety features are in good working order. Additionally, records of all inspections and maintenance should be kept for reference and compliance with safety regulations.</p>

- Q: This question asks for a comparison of the pros and cons of utilizing hydraulic cylinders in the context of building hoists.

- <p>Hydraulic cylinders in building hoists offer several advantages, including high force output, compact size, and precise control. They provide smooth and controlled lifting, which is crucial for heavy construction materials. Additionally, hydraulic systems can generate large amounts of force with relatively small cylinders, making them space-efficient. The disadvantages include potential leaks, which can be hazardous, and the need for regular maintenance to ensure the system's reliability. Hydraulic systems can also be more complex to install and repair compared to electric or manual systems. Furthermore, they require a constant power source, which might not always be readily available on construction sites.</p>

- Q: This question asks for a comparison between lifting equipment used in indoor settings versus those used outdoors, focusing on their differences.

- <p>Indoor lifting equipment is designed for controlled environments, often smaller and more precise, with features like electric chain hoists or jib cranes. They are typically quieter, require less maintenance, and are suitable for tasks like assembly, manufacturing, and warehouse operations. Outdoor lifting equipment, such as gantry cranes or mobile cranes, is built to withstand harsh weather conditions, has higher load capacities, and is often used for construction, shipping, and heavy industry. These are more robust, may require more maintenance, and are designed for larger, heavier loads over uneven terrain.</p>

- Q: The safety officer shall be responsible for the work of the construction elevator

- In a nutshell, the security officer is responsible for overseeing, checking, training, maintaining, and dismantling

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: Is it possible to operate building hoists in cold weather conditions?

- <p>Yes, building hoists can be used in cold climates, but they must be designed and maintained for such conditions. Cold weather can affect the performance of hoists, so it's crucial to use hoists specifically engineered for low-temperature operation. Regular maintenance and checks are necessary to ensure safety, as extreme cold can cause metal parts to contract and lubricants to thicken, affecting the hoist's functionality. Always follow the manufacturer's guidelines for operating hoists in cold climates.</p>

- Q: This question asks for the criteria or factors to consider when selecting a building hoist for a particular construction task.

- <p>Choosing a suitable building hoist involves considering several factors: the weight capacity required for the materials you need to lift, the height of the building or structure, the frequency of use, and the available space for installation. Ensure the hoist complies with safety standards and regulations. Consider the hoist's speed and efficiency, as well as the ease of maintenance and operation. Consult with hoist manufacturers or experts to assess your specific needs and select the most appropriate model for your construction project.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: This question asks for an explanation of the functioning of hydraulic cylinders in lifting equipment.

- <p>Hydraulic cylinders in lifting equipment operate by converting hydraulic pressure into linear mechanical motion. They consist of a cylinder barrel, a piston, and a piston rod. When pressurized fluid is introduced into the cylinder, it pushes the piston, which in turn moves the piston rod. This movement is what lifts or moves the load. The force exerted by the piston is proportional to the pressure of the fluid and the area of the piston. The cylinder's design allows for controlled and precise lifting, making it ideal for heavy-duty applications where power and control are required.</p>

- Q: What are the necessary maintenance and inspection procedures for hydraulic building hoists to ensure their safe and efficient operation?

- <p>Hydraulic building hoists require regular maintenance and inspection to ensure safety and efficiency. Daily checks should include visual inspections for leaks, proper functioning of controls, and safe operation of the hoist. Monthly inspections should cover the condition of hydraulic hoses, cylinders, and seals. Annual inspections should be conducted by a qualified professional to check the structural integrity, load-bearing components, and overall mechanical condition of the hoist. Regular lubrication of moving parts and replacement of worn components are also crucial. Always adhere to the manufacturer's guidelines and local regulations for maintenance and inspection intervals.</p>

Send your message to us

Buidling Hoist Construction Lifter CMAX Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords