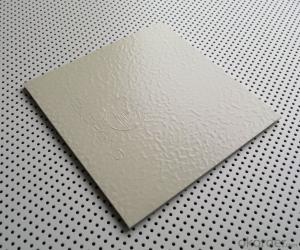

Brush aluminium composite panels( Globond)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

GLOBOND Polyester ACP consists of aluminium cover sheets; front side stove-lacquered with a high quality multi-applied polyester lacquering system; reverse side mill-finish or stove-lacquered with a high quality polyester lacquering system(back painting), sandwiching the mineral core of polyethylene hardly inflammable.

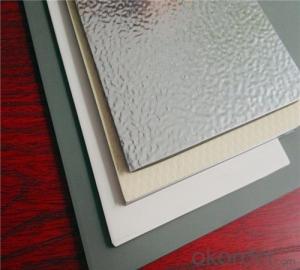

This series has the advantages to avoid the scratches caused by the traditional physical scrap-pulling technology, which brings dirt accumulation and is hard to clean away. The colorized brushes, with fluent brush lines, un-dream –of colors, and be economical for Polyester coating, have been xidely used for high-class buildings and decoration; the PVDF Brush series has the same endurance property no less than normal Kynar 500 PVDF coatings.

SPECIFICATIONS:

PRODUCT ITEM | WIDTH | LENGTH | THICKNESS | ALU-THICKNESS | COLOR & COATINGS |

Colorized Brushes | 1220mm | 2440mm | 3/4mm | 0.12-0.50mm | Regular colors listed on this chart, both PE and PVDF coatings |

Notice:

Total thickness 2mm,3mm,4mm,5mm,6mm available;

PE (Polyester) coating ranges 0.12mm and 0.20mm;

PVDF coatings ranges from 0.20~0.50mm aluminium thickness.

GLOBOND Figure Coatings Technical Data

TECHNICAL DATA | ||||

Test Item | Standard Index | PE Coating | PVDF Coating | Reference Standard |

Coating Thickness | GB/T 17748-2008 | ≥25um | ≥35um | BS 5411 |

Gloss tolerance | GB/T 17748-2008 | ≤10(gloss<70) | ≤10(gloss<70) | ASTM D523 |

Pencil hardness | GB/T 17748-2008 | ≥HB | ≥2H | ASTM D 3363-.. |

Coating flexibility | GB/T 17748-2008 | ≤2T | ≤2T | ASTMD522-93A |

Coating adhesive | GB/T 17748-2008 | ≤Class 1 | ≤Class 1 | AAMA2605-02 |

Impact resistance | GB/T 17748-2008 | 50kg.cm no crack | 50kg.cm no crack | ASTM D 2794-93 |

Boiling water resistance | GB/T 17748-2008 | No changes for 2 Hs | No changes for 2 Hs | AAMA2605-02 |

Acid resistance | GB/T 17748-2008 | 2%HCL 24 hours | 5%HCL 48 hours | ASTM D 2794-93 |

Alkaline resistance | GB/T 17748-2008 | 2%NaOH 24 hours | 5% NaOH 48 hours | AAMA2605-02 |

Special Solvents | GB/T 17748-2008 | ≥100 Ts (1kg/c㎡) in Xylene | ≥100 Ts (1kg/c㎡) in Butanone | ASTM D1308 |

Brushing resistance | GB/T 17748-2008 | ≥1000 Ts (1kg/c㎡) | ≥1000 Ts (1kg/c㎡) | ASTM D 968 |

- Q: Can the foamed cement composite board paste the aluminum plate?

- This ensures the adhesion between the aluminum plate and the backing plate.

- Q: Seeking a list of well-known aluminum-plastic panel manufacturers in South China. Thank you for the best with the corporate website

- The high-end are: OKorder Alcan Aluminum Co., Ltd. production of A Luke aluminum-plastic plate, Nantong auspicious Industrial Co., Ltd. production of Taiwan's auspicious aluminum-plastic plate, Guangdong Li Kyle Industrial Co., Ltd. auspicious licensing aluminum-plastic plate, Foshan, Guangdong Shunde District Gao Shida Building Decoration Materials Co., Ltd. Gao Shida aluminum-plastic plate, OKorder Huayuan Composite New Materials Co., Ltd. Huayuan aluminum-plastic plate, Jiangyin Litai Decoration Materials Co., Ltd. Haida aluminum-plastic plate, Jiangxi Hongtai Enterprise Group's Alite Thai aluminum-plastic plate, Guangdong Dongguan Walter Decoration Materials Co., Ltd. of the Thai-Thai aluminum

- Q: OKorder Liupanshui there is no auspicious aluminum-plastic plate to sell, to the new material of the aluminum-plastic plate, the price is not too expensive, the best manufacturers, because I amount

- You can look around, not necessarily in the Liupanshui find ah, Kunming has a cloud like building materials is aluminum-plastic plate manufacturers, sent to Liupanshui not far

- Q: By the radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature by radiator, affixed to the wall of the aluminum-plastic plate afraid of high temperature

- Hello, aluminum-plastic plate with high temperature, corrosion-resistant advantages, but a long time baking, will be relatively reduced service life. Hope can help you.

- Q: Aluminum-plastic plate production line inverter has a specific role, can specifically say it?

- Automatic spraying equipment work process is through the conveyor chain will be sprayed into the high temperature oven, after a series of baking process so that the coating attached to the paint to be sprayed, and then sent by the transmission chain, the workers removed from the chain inspection, qualified Warehousing. Its electrical control system requirements can be adjusted according to different spray conveyor chain speed, in order to ensure adequate high temperature heating time, theoretically realized should be very simple, but because the conveyor chain is longer, the use of a single motor drag is very difficult, so the design Using two motors, which in turn a key issue is how to ensure that the two motor synchronization? Because if the synchronization will lead to the accumulation or breakage of the conveyor chain lead to the production can not be carried out, the three crystal inverter in the life of the speed of the death cycle control effectively solve the synchronization problem.

- Q: How will aluminum-plastic plates separate aluminum and plastic? As far as possible with the machine separation, where to purchase the kind of machinery and equipment?

- Is the particles or how big block ah

- Q: Aluminum plate, aluminum veneer What is the difference, were used in where

- Ceiling material after 10 years of development, technology is constantly updated, the first generation of products is gypsum board, mineral wool board; second generation is PVC; third generation of products is metal ceilings. And metal ceilings and aluminum slab plate came from behind, the same day, the current market is also divided into several grades of aluminum slab: the first class of aluminum-magnesium alloy, also contains part of the manganese, the biggest advantage of the material is good antioxidant capacity, At the same time because of the addition of the amount of manganese, in the strength and stiffness has improved, is the best material for the ceiling. The second type of aluminum-manganese alloy, the plate strength and stiffness slightly better than aluminum-magnesium alloy, but slightly less than the antioxidant capacity; the third category of aluminum

- Q: Want to put the silicone plate into a right angle u line stick to a box outside, now do not know how to get that corner, will not use a wallpaper knife point it, cutting the kind of tool can use aluminum? Everyone who knows, tell me, thank you ah.

- You can cut the kind of aluminum-plastic plate tool, but the aluminum-plastic plate was 5mm Oh How thick is your silicone?

- Q: 30-storey residential building roof concrete flower frame decorated with aluminum-plastic plate, please apply to apply lightning belt can not do? Using aluminum-plastic plate grounding

- It is recommended to take the mine to do, can not cut corners to save trouble.

- Q: What kind of material is it under these two? What's the difference?

- Strictly speaking, these materials in the name of the time should follow a certain law and norms, easy to understand, but many manufacturers or new products behind the speculators are innovative, engage in concepts, grandstanding, highlight the purpose of advertising and other purposes , Chaos naming phenomenon on the resulting.

Send your message to us

Brush aluminium composite panels( Globond)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords