Biodegradable Clear Packaging Tape 40 Micron Low Noise BOPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

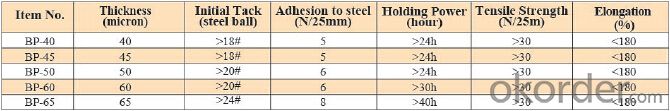

Typical Physical Reports of PVC Electrical Tape

Description

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

Application

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

Packaging & Delivery

Packaging Detail:

Log Roll: Width1280mm; length according to customers’ requirements

Cut Roll: As per customer’s requirements

Delivery Detail: within 10-12 working days after receiving your deposit

Service

Sample of Bopp Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service

Well-trained & experienced sales representative are ready to answer you.

- Q: Are there any specific instructions for reusing packaging tape?

- Yes, there are a few specific instructions for reusing packaging tape. Firstly, ensure that the tape is still in good condition and is not torn or damaged. Gently peel off the tape from the package, being careful not to rip it. Next, find a clean surface to roll the tape onto, such as a smooth piece of cardboard or a tape dispenser. Avoid folding or crumpling the tape as it may lose its adhesive properties. Finally, when reusing the tape, make sure to press it firmly onto the new package to ensure proper adhesion.

- Q: Can packaging tape be used for bundling items together?

- Absolutely, packaging tape is perfect for bundling various items together. It serves as a reliable means to firmly secure and hold multiple objects, particularly when engaged in shipping or relocating. Engineered to possess strength and dependability, packaging tape ensures a steadfast grip that effectively keeps items tightly bundled. Frequently employed for the purpose of bundling boxes, packages, or any other items necessitating cohesion during transportation or storage.

- Q: How does packaging tape adhere to surfaces?

- Packaging tape adheres to surfaces through the use of adhesive materials, typically made of acrylic or rubber. These adhesives have a sticky nature that allows them to bond with various surfaces, creating a strong and durable seal. The adhesive properties of packaging tape enable it to stick securely to different materials, ensuring that packages remain properly sealed during transit or storage.

- Q: Has anyone done a tape cut? What about profit?

- This saying is very reasonable, generally 2.5 square even high profits, sometimes with packing, a tape can earn 3 dollars a day, at least to go more than 300 pieces of goods to be profitable, or than dealers, my home is tape cutting

- Q: Can packaging tape be used for sealing plastic clamshell packaging?

- Indeed, plastic clamshell packaging can be effectively sealed using packaging tape. Tailored to securely seal a wide range of packaging materials, packaging tape boasts a robust adhesive bond that effectively binds the clamshell packaging, thereby preventing any unwanted opening during the transportation or handling stages. Moreover, the durability and tear resistance of packaging tape guarantee the continuous protection and sealing of the clamshell packaging throughout the entirety of its distribution journey.

- Q: Does packaging tape come in different textures?

- Indeed, there is a variety of textures in packaging tape. Although the usual packaging tape is smooth and glossy, there are alternative textures to choose from. For instance, rubberized tapes possess a soft and grippy texture, while paper-based tapes have a rougher texture akin to masking tape. These textured tapes serve specific functions, like offering enhanced grip or adhering to challenging surfaces. Nevertheless, it is vital to recognize that textured packaging tapes may possess diverse adhesive properties and may not be suitable for every application.

- Q: What are the considerations for using packaging tape on plastic or polyethylene bags?

- There are several factors to consider when using packaging tape on plastic or polyethylene bags. To begin with, it is crucial to choose the appropriate type of packaging tape for these surfaces. Certain tapes may not adhere well to plastic or polyethylene, resulting in poor adhesion and easy peeling. It is advisable to opt for tapes specifically designed for these materials, as they are typically formulated with adhesive that adheres properly. Another factor to take into account is the tape's strength and durability. Plastic bags are often lightweight and flexible, so it is important to select a tape that can provide sufficient strength to secure the bag's contents. Look for tapes with a strong adhesive backing that are resistant to tearing or stretching. Consideration should also be given to temperature and environmental conditions. Extreme temperatures can impact the tape's adhesive properties, leading to decreased adhesion or brittleness. If the bags will be exposed to high or low temperatures, it is recommended to choose a tape specifically designed for those conditions. Furthermore, it is essential to ensure that the tape does not cause any damage to the plastic or polyethylene bags. Some tapes may have strong adhesives that leave residue or cause harm when removed. Look for tapes labeled as having low residue, easy removal, or being safe for use on these surfaces. Lastly, aesthetics and presentation should be considered. Packaging tape is available in various colors and designs, allowing you to choose a tape that complements the bag's appearance or branding. It is important to make sure that the tape does not obstruct any important information or barcodes on the bag. In conclusion, when using packaging tape on plastic or polyethylene bags, it is important to consider selecting the right tape, ensuring strength and durability, taking into account temperature and environmental conditions, preventing damage to the bags, and considering aesthetics and presentation.

- Q: Can packaging tape be used for sealing plastic lunch boxes?

- Yes, packaging tape can be used for sealing plastic lunch boxes. Packaging tape is designed to be strong and adhesive, making it suitable for sealing various types of materials, including plastic. It can provide a secure seal that helps to keep the contents of the lunch box fresh and protected. However, it is important to note that using packaging tape on plastic lunch boxes may leave residue or damage the surface of the box when removed. It is recommended to use tape specifically designed for sealing food containers or look for alternative methods such as rubber bands or clips that are designed to secure plastic lunch boxes without causing any damage.

- Q: Is packaging tape safe to use on plastic hangers?

- Packaging tape is generally safe for use on plastic hangers, as it is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it is important to take into account the type of plastic hanger and its intended purpose. While packaging tape may be suitable for temporarily securing clothes on a plastic hanger, it could potentially leave residue or cause damage if left for an extended period. It is recommended to test a small area of the hanger first to ensure that the tape does not cause any harm or leave marks. Moreover, if the plastic hanger is used for displaying or storing delicate or valuable clothing, it might be better to consider gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

- Q: Can packaging tape be used for heavy-duty packaging?

- Indeed, heavy-duty packaging can utilize packaging tape. Assorted varieties of packaging tapes can be found in the market, some of which are specifically engineered to withstand the challenges posed by heavy or bulky packages. Typically, these tapes are crafted using resilient materials such as reinforced fibers or potent adhesives, offering exceptional strength and ensuring secure packaging. They possess the capability to securely bind rigid and weighty boxes, preventing any unravelling or tearing during transportation. When selecting packaging tape for heavy-duty packaging, it is vital to take into account both the weight and dimensions of the package, as well as the unique requirements of the shipping or handling process.

Send your message to us

Biodegradable Clear Packaging Tape 40 Micron Low Noise BOPP Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords