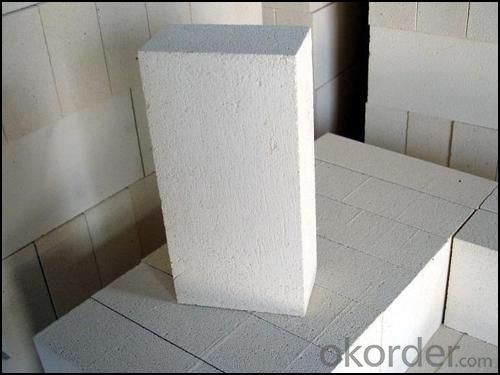

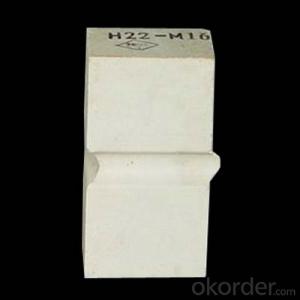

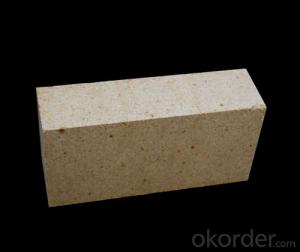

Mullite Brick Blast Furnace Corundum Mullite Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product features: the blast furnace by using artificial fused corundum mullite bricks or sintering corundum and mullite raw materials as the main raw material, after high pressure forming, high temperature sintering, the main mineral composition of mullite and corundum phase. Product has white appearance, size accurate, it has excellent high temperature performance and chemical erosion resistance, mainly used for blast furnace bottom and furnace water-analogy-simulation, is one of the big blast furnace in a high-level "ceramic cup" material.

|

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- Semisilica brick: the content of Al2O3 is 15% ~ 30% of aluminium silicate refractory products. Manufacturing products are semi silica quartz containing impurities or native clay kaolin, refractory clay or kaolin beneficiation tailings and the pyrophyllite

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- If there is no mark, ask the laboratory of the production factory to analyze any chemical or physical items. Or, check the national standard, the national standard has the basic requirements of the physical indicators

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Mullite is formed by the reaction of alumina with silica. The main difference between him and alumina is that:Hardness: alumina is harder than mullite, but two are tough enough, and are not easy to break.Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.

- Q: Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- Under strong alkaline conditions, aluminum is separated from other metal ions by the amphoteric nature of aluminum.

- Q: The introduction of mullite brick

- General alumina content in 65% ~ 75% between. In addition to mullite, the mineral composition contains lower amounts of glass phase and square quartz, and alumina containing a small amount of corundum.

- Q: The difference between the high aluminum corundum brick and corundum mullite brick

- Tiles are called floor tiles, floor tiles, polished tiles and glazed tiles are glazed tiles, bricks are samples of all kinds of tiles, ceramic tiles will be placed in the tile shop, tiles are also divided into outer wall tiles and inner wall tiles, modern brick and antique brick

- Q: What are the varieties of polycrystalline mullite?

- PNF-100 seriesThe PNF-100 series are made of polycrystalline mullite fiber cotton felt to cut, compress, and wrap into blocks without any adhesive.Characteristic: thermal shock resistancelow thermal conductivityLight weightSound absorption propertyLow thermal storage

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- Mullite refractory bricks can be used in construction, but their price is too high. We choose high alumina brick to meet the demand.

Send your message to us

Mullite Brick Blast Furnace Corundum Mullite Bricks

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords