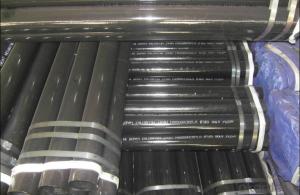

Black ASTM A106 Gr.B Sch40 seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Thickness: | 2.5 - 80 mm | Section Shape: | Round | Outer Diameter: | 21.3 - 610 mm |

| Place of Origin: | China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Structure Pipe |

| Technique: | Hot Rolled | Certification: | API | Special Pipe: | Thick Wall Pipe |

| Alloy Or Not: | Non-alloy | Grade: | 20#,45#,16Mn,10#-45# | Standard: | GB/T 8163-1999,GB/T 8162-1999,ASTM A106-2006,API 5CT,GB,ASTM,API |

Packaging & Delivery

| Packaging Detail: | In bundles or as you demand. |

| Delivery Detail: | As fast as we can. |

Specifications

1. sizes range: 21.3-610mm

2. Standard: ASTM A106 Gr.B/API

3. API ,ISO CERTIFICATE APPROVED

4. 80000TONS STOCK PIPES.

| Grade: 20#, 45#, 16Mn, 27SiMn | Thickness: 7 - 45 mm | Section Shape: Round |

| Outer Diameter: 133 - 325 mm | Place of Origin: Liaochen China (Mainland) | Secondary Or Not: Non-secondary |

| Application: Structure Pipe Fluid Pipe Petroleum casing pipe | Technique:Hot Rolled | Certification: API |

| Alloy Or Not: Non-alloy | technology: seamless | material: ASTM A 106 Q 345 ... |

Packaging & Delivery

| Packaging Detail: | seaworthy wooden cases/steel framed cases/simple packing/as customer request |

| Delivery Detail: | according to customer demand,the earliest time is 10days |

Specifications

ASTM A 106 Gr.B seamless carbon steel pipe

Material: ASTM A 106 .GB 8162 8163 API5CT

Package:oil coating&in bundles

Product name | ASTM A 106 Gr.B seamless carbon steel pipe |

Standard | GB ASTM |

Thickness | 2.5-80mm |

Outer diameter | 21.3-610 mm |

Length | 5.8m 6m 12m or as customer demand |

Used area | Petroleum,chemical,power, gas, water, metallurgy, shipbuilding, construction , etc Or as customer demand |

Package | In bundles. Ends can be beveled or square cut, End capped |

Certification | ISO9001.2000, , API, Mill Test Certificate |

Thirdparty inspection | SGS, or as customer demand |

Remark | We can customer made for special requirement |

- Q: What is the average cost of steel pipes?

- Several factors, including size, grade, and quantity of steel pipes needed, as well as current market conditions, can cause the average cost of steel pipes to vary. Typically, steel pipes range in cost from $500 to $1500 per ton. Nonetheless, it should be emphasized that this is only a rough estimation, and prices may fluctuate due to factors such as demand, location, and quality. For more precise pricing information based on specific project requirements, it is advisable to contact suppliers or manufacturers.

- Q: What is the difference between steel pipes and PVC-M pipes?

- Steel pipes are made of a strong and durable metal, while PVC-M pipes are made of a thermoplastic material known as polyvinyl chloride modified. The main difference lies in their composition and characteristics. Steel pipes are typically heavier and more robust, offering greater strength and resistance to high pressure and temperature. On the other hand, PVC-M pipes are lightweight, flexible, and corrosion-resistant, making them ideal for applications where chemical resistance and ease of installation are crucial factors.

- Q: How are steel pipes used in the manufacturing of shipbuilding and offshore structures?

- Steel pipes are a necessity when it comes to manufacturing shipbuilding and offshore structures. Their strength, durability, and resistance to corrosion make them the perfect choice for the challenging marine environment. When it comes to shipbuilding, steel pipes serve various purposes. They are primarily used in constructing the hull, which provides structural support to the ship. Steel pipes are responsible for forming the keel and frames, ensuring the hull's shape and strength. By welding these pipes together, a strong and rigid structure is created, capable of withstanding the forces experienced during navigation. Additionally, steel pipes find use in constructing different systems aboard the ship. They are essential components of the piping system, responsible for transporting fluids like fuel, water, and oil throughout the vessel. Furthermore, steel pipes contribute to the ventilation and air conditioning systems, guaranteeing proper airflow and temperature control within the ship. In offshore structures, such as oil rigs and platforms, steel pipes play a vital role. These structures endure extreme environmental conditions, including severe weather, high pressure, and corrosive saltwater. Steel pipes are instrumental in fabricating load-bearing components like legs and risers. Their strength and stability allow the structure to withstand the forces of waves, wind, and drilling operations. Moreover, steel pipes are crucial in constructing subsea pipelines. These pipelines facilitate the transportation of oil, gas, and other fluids from offshore drilling sites to onshore facilities. Steel pipes are preferred due to their high tensile strength and ability to withstand the high pressure and corrosive conditions found in subsea environments. Overall, steel pipes are indispensable in the manufacturing of shipbuilding and offshore structures. Their exceptional strength, durability, and corrosion resistance make them the preferred choice for constructing hulls, systems, and load-bearing components. Without steel pipes, the construction of ships and offshore structures would compromise safety, reliability, and longevity.

- Q: What is the maximum length of steel pipes available?

- The maximum length of steel pipes available can vary depending on the manufacturer and specific application. However, steel pipes can typically be found in lengths ranging from 20 feet (6 meters) to 40 feet (12 meters) or even longer in some cases.

- Q: How are steel pipes used in the construction of pipelines?

- Steel pipes are commonly used in the construction of pipelines due to their strength, durability, and resistance to corrosion. They are typically laid down and welded together to form a continuous pipeline that can transport various fluids, such as oil, gas, or water, over long distances. The steel pipes provide a reliable and efficient means of distribution, ensuring the safe and efficient transfer of resources in the construction industry.

- Q: Can steel pipes be used for transporting liquids and gases?

- Yes, steel pipes can be used for transporting both liquids and gases. Steel pipes are known for their durability, strength, and resistance to corrosion, making them suitable for a wide range of applications, including the transportation of fluids and gases. They are commonly used in industries such as oil and gas, water supply, sewage systems, and chemical processing plants. Steel pipes provide a reliable and efficient means of conveying liquids and gases over long distances, ensuring the safe and efficient transportation of these substances.

- Q: What is the role of steel pipes in sewage systems?

- The role of steel pipes in sewage systems is to provide a durable and reliable means of transporting wastewater and sewage from homes, businesses, and other sources to treatment plants or disposal sites. Steel pipes are known for their strength, corrosion resistance, and longevity, making them suitable for withstanding the harsh and corrosive nature of sewage. They are capable of handling high-pressure flows and can withstand the weight and pressure of the surrounding soil. Additionally, steel pipes are often used in larger diameter applications due to their ability to carry larger volumes of sewage efficiently.

- Q: How are steel pipes used in railway infrastructure?

- Steel pipes are used in railway infrastructure for a variety of purposes. They are primarily used for constructing and maintaining railway tracks, as they serve as the support structure for the rails. Steel pipes are also used for the fabrication of various components such as bridges, signal systems, and overhead power lines. Additionally, steel pipes are utilized in the construction of tunnels, culverts, and drainage systems to ensure proper water management along the railway lines.

- Q: How do steel pipes handle thermal expansion?

- Steel pipes handle thermal expansion by expanding and contracting with changes in temperature. When the pipe is heated, it expands in length and diameter, and when it cools down, it contracts. To accommodate this expansion and contraction, steel pipes are usually installed with expansion joints or loops that allow them to flex and absorb the thermal expansion without causing damage or stress on the pipe or its connections. This helps to prevent leaks, buckling, or structural failures caused by the expansion and contraction of the steel pipe.

- Q: How do you measure the diameter of a steel pipe?

- To determine the diameter of a steel pipe, various methods can be employed based on the tools accessible and the required accuracy. Here are several commonly used techniques: 1. Utilizing calipers: The most precise approach involves employing a set of calipers. Expand the calipers to their maximum width and then gradually close them around the pipe until they fit snugly. The diameter of the pipe will be indicated by the measurement displayed on the calipers. 2. Tape measure or ruler: In the absence of calipers, a tape measure or ruler can be employed. Wrap the tape measure or ruler around the pipe's circumference, ensuring a snug fit without excessive tightness. Divide the measurement by pi (3.14) to obtain the diameter. Although this method may not offer the same accuracy as calipers, it can provide a rough estimate. 3. String or flexible tape: Another option is to employ a piece of string or flexible tape. Wrap it around the pipe's circumference and mark the point of overlap. Utilize a ruler or tape measure to determine the length of the marked section. Divide this measurement by pi (3.14) to ascertain the diameter. 4. Implementing a pipe gauge: A specialized tool known as a pipe gauge can be utilized for measuring pipe diameter. It comprises a series of circular holes accompanied by corresponding diameter labels. Simply insert the pipe into the hole that best matches its size, and the label will indicate the diameter. Bear in mind that it is crucial to measure the diameter at multiple points along the pipe to account for any irregularities or inconsistencies. For accurate measurements, it is advisable to take multiple readings and calculate the average diameter.

Send your message to us

Black ASTM A106 Gr.B Sch40 seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords