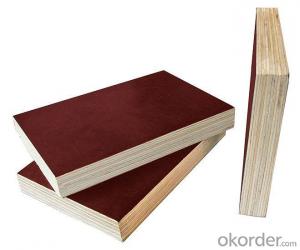

Phillips Plywood Bintangor Face and Back Poplar Core BBCC Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Bintangor plywood

Face/Back: Bintangor

Core: Poplar,Hardwood,Pine,Birch,Eucalyptus,Combi etc

Size: 1220×2440mm,1250×2500mm,1220×2150mm,1830×3660mm etc

Thickness: 2.7-30MM

Thickness Tolerance: +-0.1mm~0.3mm <6mm

+-0.3mm~0.5mm >6mm

Glue:WBP/MR/MELAMINE/E0/E1/E2

Grade:BB/BB BB/CC CC/CC etc

Moisture: 8-14%

MOQ: 40HQ

Packing Details: 20GP 8pallets/21M3

40GP 16pallets/42M3

40HC 18pallets/53M3

Payment Terms: 30%T/T in advance,70%L/C

Delivery Time: 15 to 20 days after receiving 30%T/T down payments

Commercial Plywood Quality Standard (OKOUME and BINTANGOR F/B, POPLAR CORE) | ||||||||||||||

Defects | Unit | Face | Back | |||||||||||

BB/BB Grade | BB/CC Grade | BB/BB Grade | BB/CC Grade | |||||||||||

Pin Knots | Allowed | |||||||||||||

Life knots | Maximum diameter (mm) | 19 | 25 | 19 | 30 | |||||||||

Maximum number per m2 | 2 | 3 | 2 | 5 | ||||||||||

Half-Life Knots; Dead Knots(not fall off) ; Inbarks

| Altogether

| Maximum number per m2 | Not allowed

| 2 | Not allowed

| 4 | ||||||||

Half Life Knots

| Maximum diameter (mm) | Not allowed

| 10 | Not allowed

| No limitation

| |||||||||

Dead Knots(not fall off) | Maximum diameter (mm) | Not allowed

| 4 | Not allowed

| 20 | |||||||||

Inbarks

| Maximum diameter (mm) | Not allowed

| 15 | Not allowed

| 20 | |||||||||

Splits | Closed | Not allowed

| Not allowed

| Not allowed

| ≤2x300mm permitted; must repair by similar color putty(2x300mm | |||||||||

Insect Holes | Maximum diameter (mm) | Not allowed

| 2 | Not allowed

| 4 | |||||||||

Maximum number per m2 | 4 | 4, if<2mm, there is no limitation on the number | ||||||||||||

Face Contamination | Maximum area (% of total surface) | Not allowed

| Not allowed

| Not allowed

| 0.5 | |||||||||

Discoloration | Maximum area (% of total surface) | Not allowed | 5 | Not allowed | 40 | |||||||||

Rot | Maximum area (% of total surface) | Not allowed

| ||||||||||||

Veneer shortage and damage of four corners | Not allowed

| Not allowed

| Not allowed

| Not allowed

| ||||||||||

Delamination | Not allowed | |||||||||||||

Blisters | Not allowed | |||||||||||||

Sandthrough | Not allowed | |||||||||||||

Torn Grain

| Maximum area (% of total surface) | Not allowed

| Not allowed

| Not allowed

| 5 | |||||||||

Excess Sanding | Max mm2 per m2 | Not allowed

| ||||||||||||

Mending | Maximum size per surface

| Not allowed

| Not allowed

| Not allowed

| ≤50x100mm (boat mending) ≤50x100mm | |||||||||

Maximum number per surface | 3 | |||||||||||||

Core Grade

| First grade and second grade mixed. For 3mm,must be first grade | |||||||||||||

Core voids | ≤3mm, but it can not affect the intensity | |||||||||||||

Overlap and Splits at the Other Cores | Maximum length (mm) | ≤10mm

| ||||||||||||

Overlap and Splits at the Core which Adjacent to the Top and Bottom Veneers

| Maximum width (mm)( | Not allowed

| 1.5 | Not allowed

| 3 | |||||||||

Maximum number

| 2 | 3 | ||||||||||||

Core mending | Must mend by wood-wool | |||||||||||||

Panel edge | Must smoothly | |||||||||||||

Hollowness/Imprints/Bumps | Maximum surface (mm2) | Not allowed

| 20 | Not allowed

| 40 | |||||||||

Maximum number per m2 | 1 | 1 | ||||||||||||

Maximum depth (mm) | 0.4

| Allowed if there is no breach

| ||||||||||||

Tolerance(公差)

| 1. Length is +/-1mm 2. Width is +/-0.5mm 3. Thickness <9mm +/-0.3mm ≥9mm +/-0.5mm 4. MC: <9mm 8-12%;≥9mm 8-14% 5. Veneer thickness tolerance: Not below 0.3mm after sanding | |||||||||||||

- Q: What is the general use of plywood in decoration works?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: What does plywood mean and its synthesis?

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides.

- Q: What are the further processing of plywood?

- Resin Treated Plywood Paste Plywood Plywood with resin impregnated or impregnated with other methods.

- Q: Plywood can improve timber utilization and is a major way to save wood.

- side panels are made of pure solid wood, do not use any other form of wood-based panels

- Q: What is the best way to fix multi-layer plywood?

- The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: Plywood is a common material for furniture?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on. The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q: What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q: What are the key points for plywood selection?

- if you do not consider the panel pattern and color, should also be based on the environment and reasonable cost Selection of plywood grade, category

- Q: Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

Send your message to us

Phillips Plywood Bintangor Face and Back Poplar Core BBCC Grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords