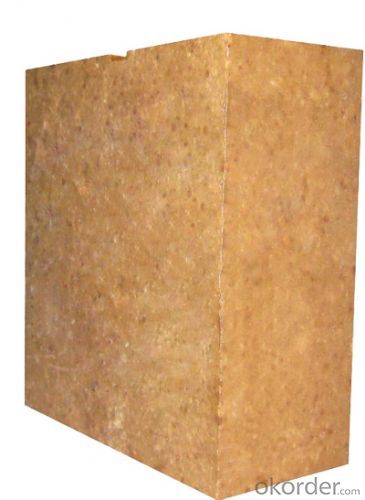

High Alumina Brick - Best Manufacturer in China Refractory Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Silicon Carbide (SiC) |

| SiO2 Content (%): | ≥95 | Al2O3 Content (%): | ≤1.0 | MgO Content (%): | international standard |

| CaO Content (%): | ≤3 | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | international standard |

| SiC Content (%): | international standard | Brand Name: | CNBM | Name: | Refractory Firebrick |

| Apparent porosity: | ≤22 | Bulk denisity: | ~1.9 | Creep rate: | ≤0.2 |

| Refractoriness: | ≥1710 | Refractoriness Under Load: | ≥1650 | Permanent Linear Change: | ±0.2 |

| Cold Crushing Strength: | ≥40 | Fe2O3: | ≤1.0 | Al2O3: | ≤1.0 |

Packaging & Delivery

| Packaging Details: | international standard package |

Best Manufacturer In China Refractory Firebrick

Item | Lightweight Insulation Brick | ||

Al2O3 % | 55 | ||

Fe2O3 % | 1.6 | ||

Bulk density g/cm3 | 1.3 | ||

Cold crushing strength Mpa | 9.0 | ||

Reheating Linear Change % | 1400°C×12h (-0.7) | ||

Thermal conductivity W/M·K (350°C±25) | 0.47 | ||

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

- Q: What is fireproof concrete?

- A series of concrete with fire resistance and heat resistance is made of Portland cement series as cementing material and heat-resistant material as aggregate. Silicate fireproof heat-resistant concrete with Portland slag cement, Portland cement and water glass as cementing material, broken clay brick, clay, cement clinker, broken high alumina brick as aggregate.

- Q: How much is one ton of high alumina refractory brick?

- High alumina refractory brick according to the different content of AL2O3 is divided into grade, grade one and grade two, and grade three high aluminum brick, Zhengzhou Kang Hui refractories factory price in 800-1900 yuan / ton, stable quality, are exported to the domestic and foreign markets.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: How to reduce porosity of high alumina brick

- High alumina brick used as refractory products in refractory material, has a great application in masonry kilns, insiders pointed out that the quality of high alumina brick general porosity and it has a great relationship! So, how to reduce the porosity of high alumina brick rate is very important!

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- High R.U.L, low creep high alumina brick [1] is using high grade bauxite, fused corundum, fused mullite as main raw material of high-grade refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What is the difference between metal compounds and metal solid solutions?

- Sigma phase belongs to Affirmative system, there are 30 atoms in the unit cell, two element alloy, sigma phase formation is related with the following conditions: (1) the atomic size difference, phase difference between the maximum sigma atomic radius of a tungsten cobalt, the atomic radius difference is 12%. (2) there is a set of cubic lattice elements (coordination number 8), and another component is face centered cubic or dense six square lattice (coordination number is 12). (3) appear in "average number of races" (s+d layer electron number) in the range of 5.7 ~ 7.5. The region of the presence of sigma in the two - element alloy is shown in table 3. In the three element system, the concentration and temperature range of the formation of the sigma phase are affected by the addition of third components. Usually in chromium stainless steel in Fe Cr phase, in Fe - Cr - Mn three yuan, sigma phase iron chromium and chromium can form Mn two element, when the addition of manganese in stainless steel, will promote the formation of sigma phase, and stabilizes the wide temperature range. Many of the Fe Cr alloy elements. The phase temperature range increases. In less than 820C stable Fe Cr phase, silicon promotes the formation of D phase and the stable temperature increased to 900 to 960 DEG C, manganese and molybdenum can improve the temperature stability of sigma phase to 1000 DEG C.

- Q: The difference between clay bricks and clay bricks

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).Solid bricks and porous bricks are mostly used for load-bearing structural walls. Hollow bricks are mostly used in non load bearing structures.

Send your message to us

High Alumina Brick - Best Manufacturer in China Refractory Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords