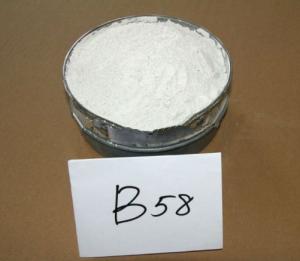

Bentonite Organic Type B58

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

Advantage Easy-to-Use,

Overall-Persistent Making Efficienty for Rheology,

Complete Spread in the condition of middle cutt

| Product Name | Organic Bentonite |

| Model Number | B58 |

| Description | As an improved assistant material of anti settling and thickening, our new organic |

| bentonite B58 was mainly applied for semi-polarity or high-polarity system, with a good | |

| efficiency of thixotropy, and anti settling. B58 organic bentonite can reduce the stock | |

| of other types of bentonite and it can be applied for all kinds of systems. | |

| Application | Nitrolacquer, Epoxy Resin Paint, Polyester Paint, Vinyl Ester Resin Paint, Polyester |

| Varnish, Marine Paint, Heavy Anti-Corrosive Paint, Chlorinted Rubber, Polyacrylic Acid | |

| Paint, Bituminous Paint, Base Paint, Adhesive, Printing Ink, Sealing Compound etc.. | |

| Dosage | The dosage of organic bentonite depends on the thickening level of requirement, the |

| control of sag resistance and anti-settling result for pigment etc. Normal dosage is | |

| 0.2%-3.0%, the dosage is better to be same as replacement when do the replacement, | |

| then adjust accroding to the specific requirement,normally less than traditional one. | |

| Advantage | Easy-to-Use, Overall-Persistent Making Efficienty for Rheology, Complete Spread in the |

| condition of middle cutting, Simplifying Viscosity & Adjustment after sag resistance, | |

| Good Stability of Heating, Good Stability of Storage, good character for general use. | |

| Physical Property | Composition - Organic Montmorillonite Ramification |

| Appearance - Super Fine Powder | |

| Diameter of Grain under Complete Spread - 1-3um | |

| Colour - Parchment (Cream) | |

| Density (g/cm3) - 1.7 | |

| Mositure Level (%) - less 3.0 | |

| Burning Disappearing (%) - less 38 |

- Q: What color is the normal appearance of bentonite?

- It has a lot to do with the local quality, but remember it is a kind of loess. It may be dark brown. "Sensory unqualified" too general, and personally feel that only to deviate from the Yellow Brown can be, the particle size must be qualified. There are a lot of light tan here in Jiangxi. Physical and chemical indicators, expansion must be achieved.

- Q: How does bentonite dry?

- The bentonite drier is a drying device for processing large amount of drying machine used in bentonite is according to the specific characteristics of bentonite, analyzed the structure of drying machine of bentonite production and quality of design.

- Q: Polyacrylamide was added to bentonite as a briquette binder, plus that type of polyacrylamide ratio

- Add some amount of amide coal powder, add 3% of high pressure roller, after extrusion, wet strength above 50, dry strength above 80

- Q: Are heavy metals easily exceeded in zeolite powder? Where is the difference between zeolite powder and bentonite?

- We are going to measure lead, fluoride, arsenic. Geology differs greatly from heavy metals

- Q: Sodium bentonite and sodium bentonite clay has the difference? What is the processing method of sodium bentonite?

- Generally: (dry process) raw ore - hand picked sand impurities - based on the amount of cation exchange, adding soda ash and additives - mixing - in the case of water content of 13--16%, Raymond grinding crushed - placed for a few days - Inspection - finished products. (wet) raw ore - hand picked sand impurities - replacement of soda solution by cation exchange, usually for more than 15 days - drying - crushing - Inspection - finished products.

- Q: Construction method of sodium base bentonite waterproof blanket

- Cutting and laying of waterproof matThe company produced waterproof pad specifications for the width of less than 6 meters, the length is less than 60 meters. When cutting, it can be cut according to construction size and can be laid transversely or vertically. When the waterproof mat is laid, all joints (transverse or longitudinal) shall be lapped only, and the bentonite powder (bentonite, daub) can be sprinkled on the joint according to the quantity of 0.4kg/m2. The seam width is larger than 25cm, once the waterproof pad appears damaged, found defects or damage, should be timely with bentonite powder (bentonite clay) or damaged parts and enlarge the size of GCL bentonite powder above 15cm (bentonite clay) local repair can be covered, edge processing by the overlapping requirements, when the slope is large, special riveting screws to avoid sliding waterproof pad.

- Q: Difference between montmorillonite and bentoniteIs montmorillonite and bentonite a kind of substance? What's the difference between them?

- The latter (bentonite) is the common name, is on the market is not pure montmorillonite (mixed with a number of other classes in clay).

- Q: Why does bentonite treat printing and dyeing wastewater well under acid condition?

- Decolorization process can be generally used coagulation and adsorption process, the removal of heavy metals can be used ion exchange method.Decolorization process need to use: powder activated carbon, decoloring agentFlocculation, flocculation, precipitation need to use: polyaluminium chloride, polyacrylamide (Yin, Yang, non).

- Q: Litter used flower fertilizer can do?

- The most important progress is the culture in the cat litter, the litter in litter is mainly early without coagulation, everyone is to receive the main cat, but with the continuous progress of CAT technology, people are not limited to such a simple storage, so again there is condensation in the sand, sand and wood. Crystal sand, bentonite sand and so on.

- Q: What is the structure of organic bentonite? Please tell me something about it

- Organic bentonite is a kind of important fine chemical raw materials. Because of its characteristics of hydrophobic, form a thixotropic gel in organic solvent, which has anti settling, thickening, anti sagging thixotropic properties. Therefore, the products are widely used in paint, printing ink, high temperature grease, sealing glue, oil drilling precision casting and quick drying putty, adhesives, plastics, asphalt, petroleum additives, chemical industry, anti settling agent, thickening agent, tackifier and suspending agent.

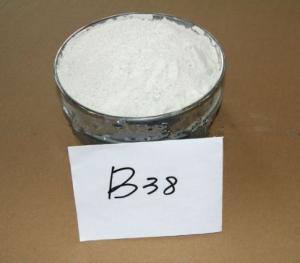

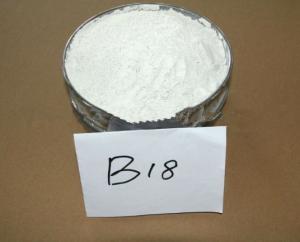

We focus on developing and utilizing bentonite products at high grade. Based on the traditional bentonite clay, we have developed many new and classic organic bentonite products for multiple fields, such as painting, coating, ink, waterproof, drilling, etc.

Our organic bentonite is mainly used in industrial fields, and is used for adding system adhesive, protecting sedimentation and controlling liquid sagging.

We are looking forward to achieving good cooperation with partners at home and abroad and creating a glorious future.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,NingBo |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Bentonite Organic Type B58

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords