Bend Plywood - Brown/Black Film Faced Marine Plywood for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Type:

Film Faced Plywood

Application:

For Construction

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| Veneer Board Surface Finishing: | Veneer Board Surface Material: | core: | |||

| glue: | moisture: | thickness tolerance: | |||

| film: |

Packaging & Delivery

| Packaging Detail: | Packaging Detail: wood pallet packing, loose packing or as customer's requirement Delivery Detail: within 2 weeks |

| Delivery Detail: | 15 days after deposit or L/C at sight |

Specifications

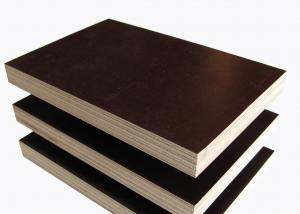

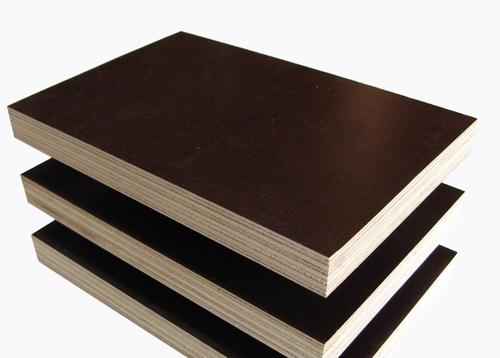

Brown/BlackFilm Face Plywood

1)size:1220*2440mm,1250*2500mm

2)core:poplar,Combi,hardwood

3)glue:WBP,MR,MLM

4)thickness:6-25m

1. Brown/Black Film Face Plywood , Marine Plywood for construction

| Size: | 915mmx1830mm,610x2440mm,1220x2440mm,1250x2500mm,1500x3000mm |

| Film: | chinese brown(240g/m2), Dynea brown(120g/m2) , black film(240g/m2) |

| Core: | poplar , birch ,hardwood core, poplar and hardwood mix core |

| Thickness: | 6mm,9mm,12mm,15mm,18mm,21mm,25mm |

| Glue: | Mr,wbp ,waterproof melamine glue |

| Density: | 530-600kg/cbm |

| Moisture: | less than 12% |

| Thickenss tolerance : | +/-0.5mm |

| Modulus of rupture: | ≥30Mpa |

| Modulus of Elasticity | ≥6000Mpa |

- Q: The structure of the plywood at the same time meet two basic principles

- the fiber direction and the table are parallel to the long core plate or the middle plate. When forming a slab, the panel and the backplate must face outward.

- Q: Class I resistant weather plywood Class II water resistant plywood

- Hard fiber board sound absorption, waterproof performance is good, durable, easy constructio

- Q: What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q: Judging wood is the standard for plywood

- Rare wood is only used to make very upscale furniture, and is often used in combination with lower-priced wood

- Q: Multilayer board and plywood difference

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: A brief introduction to plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: What are the processing defects of plywood?

- Patched Plywood Repaired plywood Defects Plywood that has been repaired with a filler or veneer patch.

- Q: What are the key points for plywood selection?

- may be damp the hidden parts and high demand for waterproof occasions should consider the use of Class I or II plywood, outdoor use of plywood should be used Ⅰ class plywood.

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q: Why is the plywood commonly used in the singular layer

- if put a piece into a striped. (Then this time there will be positive is the pattern of wood

Send your message to us

Bend Plywood - Brown/Black Film Faced Marine Plywood for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords