Bamboo / Wood Plywood, Board, Eco Construction Material, Interior or Exterior, High Strength

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Build 200™ Series | Construction Plywood Board

Description

Bamboo construction plywood board is produced from bamboo strips with outstanding performance. Bamboo plywood construction board is high strength and good toughness, less patchwork, with smooth surface, easy to remove from the mold. Thermal conductivity of bamboo plywood board is far less than steel formwork, is conducive to winter construction insulation. Bamboo plywood board is recycling, both surface and bottom can be used, with correct using for the board, recycled time is up to 10-30 times.

| Material | Dimensions | Surface | Application |

Solid engineered bamboo Adhesive: Non-Toxic, Low V.O.C. adhesives (LEED Credit Certified) Fire Rating: International Class B | Thickness: 9.5mm, 13mm, 19mm, 25mm Width x Length: 610mm x 1220mm 1220mm x 2440mm Custom Available | Grain: Vertical / Edge Grain Horizontal / Flat Grain Strand Woven Grain Color: Natural colors Custom stained | High Building Shear wall Vertical template Concrete formwork of high way, tunnel, etc. Train, car trunk flooring Container flooring Trailer wall Package panel |

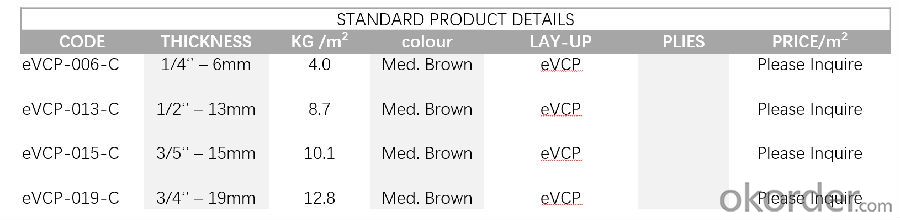

Build 200™ Series | Construction Plywood Board | Standard Product Pricing List

Note

1. Standard board sizes, 610*1220, 1220*2440 mm (width* length). Custom sizing is available, please inquire.

2. Edge profile subject to product dimension

3. Available lay-ups for different thickness.

Build 200™ Series | Industrial Ply Wood | Standard Product Details

Panel Details:

1. All pricing is based on net coverage and includes standard packaging.

2. Minimum quantities may be required for certain panel dimensions and/or colours. Please Inquire.

3. All pricing is based on med. brown (carbonized) color, Please see colour chart for available standard colours. Special colours are available, please inquire.

4. Certain series material are available in a vertical and horizontal grains only. See lamination lay-up chart for details.

5. Custom thickness, widths, lengths are available, please inquire.

Surface Treatment Details:

1.The surface treatment are environmentally friendly and can contribute to a projects LEED or other environmental certifications. Please inquire.

Packaging Details:

1. Standard packaging: Plywood are stacked with EVE protective film interleafing and strapped. Secured on each side with 6.35mm plywood and blocked for shipping protection. Each package is wrapped with PP weather protective covering, and palletized.

2. Optional ECO packaging available. Please inquire.

3. LCL shipments require increased plywood crating with micro-foam interleafing.

4. International shipments ................................ Please inquire.

5. Special packaging ........................................ Please inquire

Shipping Details:

1. Mainland China....................................... Please inquire

2. Other Country or Area............................. Please inquire

Delivery Details:

1. 13mm- stocked Med. Brown (carbonized) .......................Please inquire

2. Other dimensions, colors and lay-ups .........................45days + shipping

Notes:

1. All panel lengths over 1220*2440mm....................................Please inquire

2. Limitations may apply to certain lay-ups.

3. All sizes subject to 0.0625 inch (1.3mm) tolerance.

4. Installation of material constitutes acceptance. It is the customer's responsibility to check received product(s) from us before signing the freight carrier's paper work to ensure no damage has occurred to the finished product(s) during transit. If the customer signs off on the delivered product(s) before checking finished product(s) and damages have occurred due to transportation, It will not be our responsibility to replace any damaged product(s).

Grain Surface Detail

Vertical

Horizontal

Strand

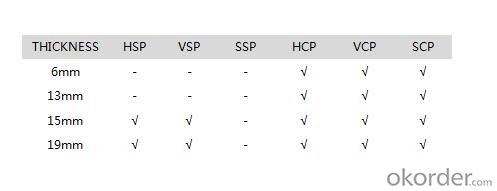

Vertical Series

VSP – Vertical Solid Ply

Unidirectional Laminated Ply(s)

VCP –Vertical Cross Ply

Cross Laminated Ply(s)

Horizontal Series

HSP – Horizontal Solid Ply

Unidirectional Laminated Ply(s)

HCP – Horizontal Cross Ply

Cross Laminated Ply(s)

Strand Series

SCP – Strand Cross Ply

Cross Laminated Ply(s)

- Q: Aluminum sheet tensile test, the sample direction is horizontal or vertical sampling? What is the relationship between the longitudinal specimen, the transverse specimen and the rolling direction of the sheet?

- Sampling is generally longitudinal (rolling direction) taken by horizontal agreement by both parties

- Q: Do pcb circuit board which several kinds of plate

- PCB circuit board plate mainly in the following categories: First, FR-1: Flame Retardant Copper Foil Phenolic Paper Laminate. IPC4101 detailed specification number 02; Tg N / A. Second, FR-4: 1) Flame Retardant Copper Foil Epoxy E Glass Fiber Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 21; Tg ≥ 100 ℃; 2) Flame Retardant Copper Foil Modified or Unmodified Epoxy E Fiberglass Laminated Laminate and Bonding Sheet Material. IPC4101 detailed specification number 24; Tg 150 ° C to 200 ° C; 3) Flame Retardant Copper Foil Epoxy / PPO Glass Cloth Laminate and Its Adhesive Sheet Material. IPC4101 detailed specification number 25; Tg 150 ° C to 200 ° C; 4) flame retardant copper clad modified or unmodified epoxy glass cloth laminate and its adhesive sheet material. IPC4101 detailed specification number 26; Tg 170 ℃ ~ 220 ℃; 5) Flame Retardant Copper Foil Epoxy E Glass Cloth Laminate (for Catalytic Addition). IPC4101 detailed specification number 82; Tg N / A;

- Q: Which master please teach about aluminum alloy doors and windows under the material calculation method? Flattened; push-pull can be the best example. Thank you!

- laser cutting Laser cutting is a new type of processing technology, has been widely used in metal cutting, glass cutting, sculpture and other industries. The laser is a kind of light, which is produced by the transition of atoms (molecules or ions, etc.), but it is different from ordinary light that the laser depends only on spontaneous emission only in the first short time, and the process is completely determined by laser radiation, So that the laser has a high coherence, high strength, high direction, laser cutting machine through the laser to produce laser, the mirror transmission and through the cluster mirror to the processed items, so that processed items (surface) by the strong heat and temperature A sharp increase, so that the point due to high temperature and quickly melt or vaporization, with the laser head of the trajectory to achieve the purpose of processing. The advantages of laser cutting machine are: the processing of the workpiece without mechanical pressure, so cut out the product with high precision, no secondary processing; cutting speed, easy operation, high degree of automation; can cut any complex shape of the product, Cut, the model compression process is more preferred, although the processing rate is slower than the punching, but it saves mold costs, low economic costs. But for the thickness of more than 6mm aluminum alloy sheet, the use of laser processing, cutting effect is not good, and the equipment on the use of high environmental requirements, equipment failure in the service after a long time.

- Q: Will the sheet metal processing bending coefficient and plate thickness, bending angle, bending radius is what is the relationship between the urgent!

- The bending factor and the thickness of the material you said bending angle ah bend the radius and bending the bending machine up and down mold, the length of the bending parts are related We are using experience value. After all, conventional standard brick algorithm does not take into account the equipment wear and tear, sheet material thickness of the situation Different thickness determines the different bending factors such as 1mm cold rolling fold 90 degrees and 2mm cold rolling fold 90 degrees Our actual situation is 1mm coefficient is 1.8 2mm coefficient is 3.5 The same angle 90 degrees is a bending factor of 60 degrees is 1/2 of the bending coefficient of 45 degrees is 1/3 of the bending coefficient of less than 30 degrees according to the different thickness of the buckle or buckle a 0.5 Material and plate thickness as different materials, the bending coefficient is different The bending radius is related to the bending machine. The standard single V or double V is even the default value of the other V slots. But there are customers who need to be too small or a large bend radius will be specific to the analysis Too small bend radius, our approach is to plan the groove to bend, so that the bending radius is very small, almost vertical right angle bending Too large bending radius, the upper mold can be used on the corresponding arc on the mold (note that the upper arc of the R is the inside of your bending R, if the outside R according to the outer R minus a plate thickness to determine the model) Or a large R30 50 or more, you can use a split bend, which requires the calculation of the cut-in angle and the last knife angle, as well as the size and angle of each knife There is a part of the length of this I think a lot or machine equipment and related to our machine a long time 1.5mm stainless steel over 1m according to the case will not use 8mm mold bending

- Q: Home improvement wardrobe what brand plate best

- Sophia, Europe, Kamandi are good ah. Hope to help you

- Q: What are the types of decorative plates?

- Decorative sheet types are blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC sheet, Aluminum plate, Aluminum plate, 3D board. Xiaobian today to simply introduce you to Glulam and PVC sheet two common life of the plate. Decorative materials are divided into two parts: part of the outdoor materials, part of the indoor materials. Indoor materials and then divided into stone, sheet, sheet, profile, wire five types. Decorative sheet is the general term for all plates, mainly: blockboard, plywood, decorative panels, MDF, Glulam, Particleboard, Fireboard, Gypsum board, PVC board, Aluminum gusset plate, Aluminum plate,

- Q: Does the net aldehyde antimicrobial sheet really be environmentally friendly?

- I am engaged in decoration, and recently our company purchased the cloud of ecological net aldehyde antimicrobial sheet, the price is higher than the average plate, with the good or good. A few days ago, the family has just finished renovation, one into no taste, even the decoration owners are really good things to see, boast that we use the material is good. Now encountered high environmental requirements of the owners we are recommended cloud ecological sheet, the general brand if the owners are not satisfied with the rework, with the cloud ecology we also worry

- Q: Which plate is not easy to swell, mildew?

- Simi 3D laser board, edge strip and finishes 360 ° perfect package core board, the core of the super seal protection, so that water can be non-porous, greatly improve the moisture resistance of the plate to prevent the door due to long-term in the kitchen temperature and humidity The environment of water swelling and mildew, double cabinet life.

- Q: What is ps plate

- PS plate Polystyrene (PS) extruded sheet Features and uses: The product is polystyrene as the main raw material, made by extrusion, free coloring, odorless and tasteless non-toxic, not to bacteria growth, with rigidity, insulation, good printing, etc., mainly for packaging, container equipment, Daily decoration, general electrical and construction and other industries. PS polystyrene decorative board is polystyrene particle molding compound in the extrusion plate on the extrusion molding of organic polymer sheet.

- Q: Home decoration need to do wardrobe, what plate is the most environmentally friendly?

- Melamine impregnated directly on the particleboard and high density board. This board is divided into two levels, E1 level and E2 level. Melamine board full name is melamine impregnated film paper facing wood panel. Is to have different colors or textures of paper into the melamine resin adhesive soak, and then dry to a certain degree of curing, will be paved in the particleboard, medium density fiberboard or hard fiber board surface, made by hot pressing. Do the wardrobe to choose the brand is better, so there will be a great quality assurance,

Send your message to us

Bamboo / Wood Plywood, Board, Eco Construction Material, Interior or Exterior, High Strength

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords