Automatic Precast Concrete Hollow Core Slab Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Precast Concrete Hollow Core Slab Casting Mould

1. Structure of Automatic Precast Concrete Hollow Core Slab Casting Mould:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Automatic Precast Concrete Hollow Core Slab Casting Mould:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

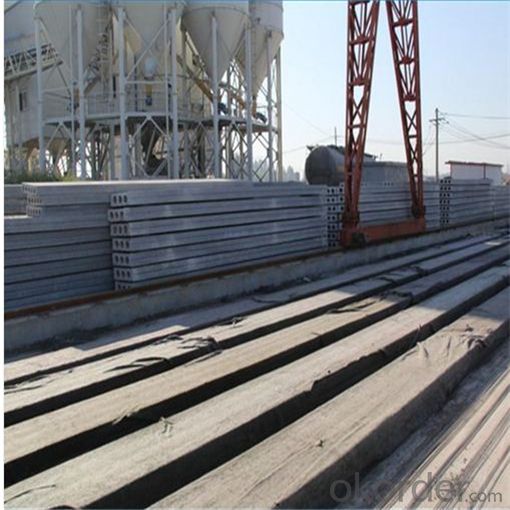

3. Automatic Precast Concrete Hollow Core Slab Casting Mould Images:

4. Automatic Precast Concrete Hollow Core Slab Casting Mould Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: I remember a famous economist said that. Poor countries are economically advantaged to use manual labor instead of advanced technology so that they can employ everyone.

- If that's a famous economist, he's a stupid, famous economist. Pure poppycock. Productivity matters. That famous economist failed Econ 101. Is it leftist darling Paul Krugman? The guy who ignored the basic fact that all wealth destruction is bad and declared the 9/11 rebuilding in NYC a positive economic event?

- Q: I just wanna know how much sea duty will they get and how much shore duty will they get? Is there a possibilty that they can get more shore duty? And yes i know i know when you are in the navy you're going to be on the sea thank you i heard that so many times lol!!!! But any answers will be great!!Thank you all and god bless

- It is likely that you will spend more time on a ship as that is where the most machinery and equipment is....unless you are posted in a motor pool (government cars etc.) but those jobs are few and far between.

- Q: Please include your reference. Thank you.

- E26:O26

- Q: What type of machinery would you consider lawn mowers and weed 'whackers'?

- confident, something that runs on gas will throw out greenhouse fumes. Even an electric powered mower will use oil. Letting the grass improve long is the greenest thank you to flow, with an occasional reducing with a push mower. And get rid of those electric powered procedures! Hand pruners are lots extra useful than a weed whacker and a rake is the suited thank you to collect up leaves.

- Q: Shouldn't insurance companies start considering this when insuring businesses?

- I know people at work you are just bad operating there machines very dangerous people w/o any imaginary friends to speak of /or to.

- Q: Please introduce a link that explain these functions in a list or categorical. I would prefer new and interesting functions.Thank you

- Fluid okorder /

- Q: I have tried so many things, but I cannot figure out how to do this. I need to wrap one fabric around a different fabric. My problem is that it not only wraps the fabric, but it gets stuck on the bar and wraps around it as well. Are there any machines that can wrap fabrics together?

- sewing machine

- Q: to other countries as another income stream. I already broker it in the USA. Is Exporting a good business?

- hg

- Q: Is there any difference between the two words? I want to name a company's name, the product is machines.By the way, what about packing and packaging? are the different. The machine is mainly packaging facilities, how can i name the company's name?

- ya 1 machine vs more than 1 machine

- Q: What kind of material is used for processing shafts?

- Meet any of the above conditions, to choose stainless steel, I commonly used 1Cr18Ni9Ti, wear resistance, a variety of resistance are very good, stable work;

Send your message to us

Automatic Precast Concrete Hollow Core Slab Casting Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords