Automatic mobile Concrete Purline Making Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic mobile Concrete Purline Making Mould

1. Structure of Automatic mobile Concrete Purline Making Mould:

Automatic mobile Concrete Purline Making Mould is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Automatic mobile Concrete Purline Making Mould:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

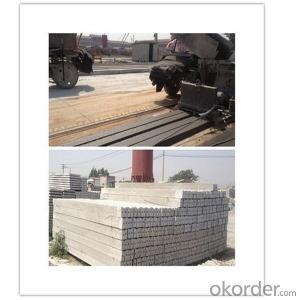

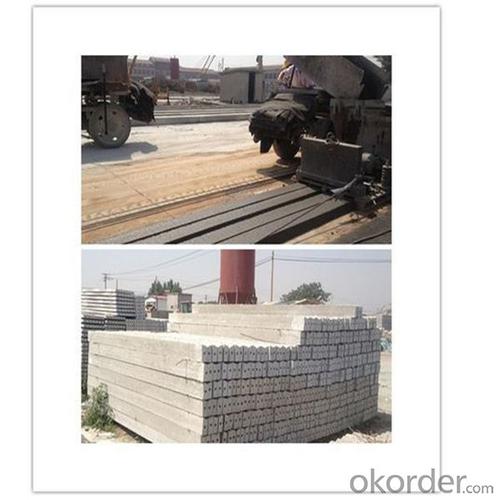

3. Automatic mobile Concrete Purline Making Mould Images:

4. Automatic mobile Concrete Purline Making Mould Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

Model no. | No. of holes | Dia. | No. and dia. of wires | Electric motor power(kw) | Vibrator Motor Power(kw) | Total Power (kw) | Max. span | Molding Speed(m/min) | Overall dimension (mm) | Weight (kg) |

60X120X140X4 | 1 | 30 | 5/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 1000 |

60X130X150X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 4 | 1.3-1.5 | 2250×900×850 | 1000 |

70X140X160X4 | 1 | 30 | 8/5 | 4 | 1.5 | 5.5 | 4.5 | 1.3-1.5 | 2250×900×850 | 1050 |

70X150X170X2 | 1 | 30 | 8/5 | 3 | 1.5 | 4.5 | 4.7 | 1.3-1.5 | 2250×900×850 | 750 |

60X110X130X4 | 1 | 30 | 6/5 | 4 | 1.5 | 5.5 | 3.5 | 1.3-1.5 | 2250×900×850 | 950 |

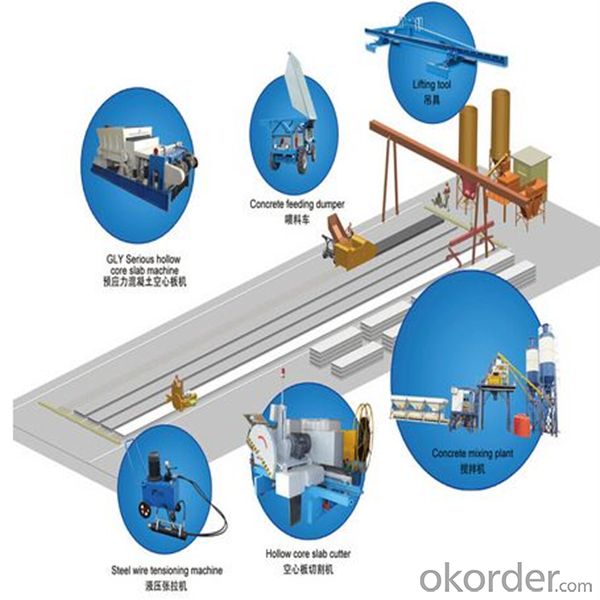

Production Line Layout

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

9. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q: I'm in a tropical country, and heck, my whole life living here. I haven't experienced this kind of heat!I'm just a student, and because of that, I have no money to buy an ice cream maker.How can I make ice cream without a ice cream maker?

- Get 2 zip lock baggys. 1 gallon and 1 sandwich bag. U put ice cubes in the 1 gallon bag and then your choice of home made ice cream ingredients in the sandwich bag. Put the sandwich bag inside the 1 gallon bag... then... shake it for 10-15 minutes and bowww ice cream

- Q: How does operating machinery under water complicate mining procedures?

- Absolute pressure at the surface is 14.7psi. Absolute pressure at 250 feet of see water for example is 126psi. That puts the machinery and people into a very different world that us surface dwellers from the get go. The BP job was at something like 7000 to 8000 feet if I remember correctly. That's about 3352psi. People can only dive to about 1000 feet of sea water. So on the BP job there were no people down there working. Everything we saw was from ROVs. Remotely Operated Vehicles. Doing things with a claw that is controlled by a joystick through a TV screen is very different from doing it with your own hands when you're right there looking at it. Even when you do have divers down there they usually only have 1 to 4 people. That's a limited team. They do not have a big box full of tools down there with them. They have the surface crew send the tools to them as needed. Salt water is not good for any kind of tool. It makes them rust and makes the seals break down. This leads to tool failure and many trips back and forth for replacements and repairs. The surface crew is usually young guys 18 to 25 who are not the most mature or reliable people in the world. Tool maintenance does not always get done properly. Divers are regular people. They are stubborn, arrogant, lazy, dumb and any other thing that you run into with coworkers anywhere. If they feel like sitting down for a break, the boss can't always keep a proper watch on them or come down and yell at them. We just finished a well abandonment job where we did the same thing with plugging a well with concrete just like the BP job and it took us 6 tries. That technique doesn't work too good at shallower depths either. This stuff is still full of bugs buts the pursuit of money keeps things moving beyond what we truly understand.

- Q: I'm specifically looking for training on heavy machinery such as bulldozers, backhoes cranes etc. The courses are given in montreal but there's a 10 year wait. If you know of any sort of training course of the sort in the 613 area code, please let me know. Thanks

- Try okorder /

- Q: Efficency , Cost-effective

- PHARMACO okorder /

- Q: I have a go cart with a 6.5 horsepower general machinery small engine. The engine starts right up first pull but as soon as I press the throttle, the engine dies. The only way to use it is if you start the engine with the throttle being pushed, but if you let it idle for about 10 seconds after that it dies. Whats going on here??? Any help would be greatly appreciated.

- clean carb...idles ok but given gas stalls....when u hit throttle u open letting in more air...not enough gas..

- Q: Machinery was purchased for $51,000 on January 1, 2009. Freight charges amounted to $2,100 and there was a cost of $6,000 for building a foundation and installing the machinery. It is estimated that the machinery will have a $9,000 salvage value at the end of its 5-year useful life. What is the amount of accumulated depreciation at December 31, 2010, if the straight-line method of depreciation is used? $10,020. $8,580. $17,160. $20,040.

- $20,040: (51,000+2,100+6,000-9,000) / 5 = 10,020 per year 2009 - 10,020 2010 - 10,020 Total = $20,040

- Q: I am planning to setup a juice processing unit and therefore need help and info on the plant and machinery either on turnkey basis or upfront selling along with technology transfer.

- I okorder

- Q: find impeller for model 09576 central machinery pump(12 volt)?

- Check out this site

- Q: Needing to know if you have elevator equipment in the back part of an office downstairs in the basement, is there anything put out by this equipment that can cause sickness?

- It's unlikely. There's more than one type of elevator, but I don't believe any of them use poisonous gas or asbestos.

- Q: Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- The steering on your car.

Send your message to us

Automatic mobile Concrete Purline Making Mould

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches