Automatic Mobile Concrete Hollow Core Roof Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Mobile Concrete Hollow Core Roof Production Line

1. Structure of Automatic Mobile Concrete Hollow Core Roof Production Line:

The machine uses hydraulic lifting system, easy to revolve. It can reduce labor intensity and improve production efficiency. Machine body adopts anti-rust technology. Key parts, like hopper are welded by stainless steel. Wearing parts like reamers, side form, vibration board, stock guide and other parts are all welded with alloy. Both sides of the wall panels can put reinforcement wires, diameter can reach 6mm. Work area is orbital or no orbital.

According to the specialty of the local materials, we provide matching method to insure customer produce standard panels (general materials: fly ash, slag, ceramsite, cinders, cinerite, pumice, vermiculite and so on). Reduce the overall cost of building, increase indoor usable space.

High production efficiency, annual output square meters above 150000m.

2. Main Features of Automatic Mobile Concrete Hollow Core Roof Production Line:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

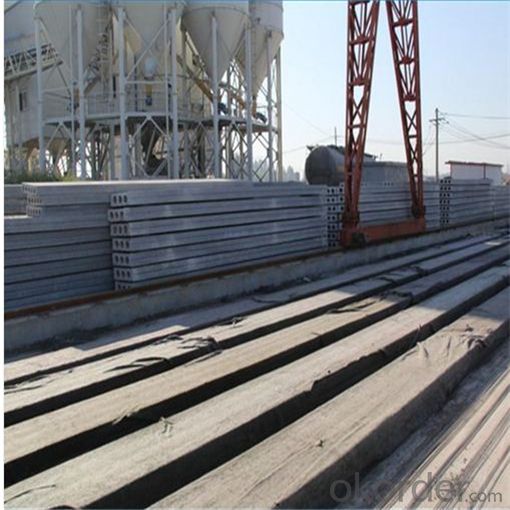

3. Automatic Mobile Concrete Hollow Core Roof Production Line Images:

4. Automatic Mobile Concrete Hollow Core Roof Production Line Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Process

Rebar tensioning

Raw materials preparing

Molding

Our customers

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: It is related to the injection unit of molding machine

- Well, see this link.

- Q: How does operating machinery under water complicate mining procedures?

- Absolute pressure at the surface is 14.7psi. Absolute pressure at 250 feet of see water for example is 126psi. That puts the machinery and people into a very different world that us surface dwellers from the get go. The BP job was at something like 7000 to 8000 feet if I remember correctly. That's about 3352psi. People can only dive to about 1000 feet of sea water. So on the BP job there were no people down there working. Everything we saw was from ROVs. Remotely Operated Vehicles. Doing things with a claw that is controlled by a joystick through a TV screen is very different from doing it with your own hands when you're right there looking at it. Even when you do have divers down there they usually only have 1 to 4 people. That's a limited team. They do not have a big box full of tools down there with them. They have the surface crew send the tools to them as needed. Salt water is not good for any kind of tool. It makes them rust and makes the seals break down. This leads to tool failure and many trips back and forth for replacements and repairs. The surface crew is usually young guys 18 to 25 who are not the most mature or reliable people in the world. Tool maintenance does not always get done properly. Divers are regular people. They are stubborn, arrogant, lazy, dumb and any other thing that you run into with coworkers anywhere. If they feel like sitting down for a break, the boss can't always keep a proper watch on them or come down and yell at them. We just finished a well abandonment job where we did the same thing with plugging a well with concrete just like the BP job and it took us 6 tries. That technique doesn't work too good at shallower depths either. This stuff is still full of bugs buts the pursuit of money keeps things moving beyond what we truly understand.

- Q: Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q: I remember a famous economist said that. Poor countries are economically advantaged to use manual labor instead of advanced technology so that they can employ everyone.

- I don't know who said it, but it sounds logical. It's better than taking out loans from the IMF.

- Q: but the problem is that some materials are not available in india and i want to search the any material with same compositions of the requird materials. so is there any website or any book from where i can find that

- Matweb okorder

- Q: Do Machinery Repairman (MR) in navy get assigned to subs?

- Probably. Subs have a lot of machinedry in them.

- Q: I need a list of machinery, and the methods of how trees are cut down. Do they only use chainsaws? or are there bigger machines that cut faster and better? plz answer, im trying to create an accurate scene in a painting ( im in the planing stages).

- I'm okorder /

- Q: Material processing technology and machinery manufacturing What is the relationship

- Parts of the various processing, heat treatment and surface treatment; parts and product assembly, commissioning, testing and coating and packaging.

- Q: I want to be an engineer who works with microchips and things like that. Are there any small projects and things which I could do at home (spending less than $100-200) just to get a feel for things?

- As stated by others, microchips and machinery are built in totally different ways. There are a number of microcontrollers on the market that give you access to hardware control while learning the software aspects, which puts off the tricky interfacing questions till later. Parallax BASIC Stamp devices and Raspberry Pi have gotten a fair amount of attention and support, the former in various robotic device projects while the latter has stronger support for communications, it seems to me

- Q: Libraries in Chicago withcollections of trade catalogs. Chicago Machinery Exchange 1900-30?

- The Newberry Library (it's in the Gold coast) has many old items. They are very knowledgeable about this type of thing, they might know where to find it if they don't have it.

Send your message to us

Automatic Mobile Concrete Hollow Core Roof Production Line

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords