Automatic Filling Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

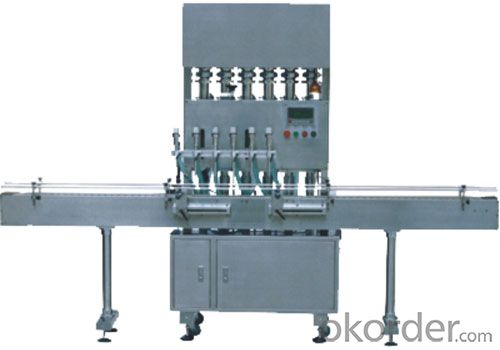

Automatic Filling Machine for Packaging Industry

1. Product Description:

Bottles are entered by the air conveyor, the speed of bottle entering is fast and bottle shape isn’t changed because of adopting hanging clamping bottleneck way. Adopting clamping bottleneck fashion to wash bottle mouth and avoid touching screw mouth, when bottle type changes, you need to change the board related with bottle diameter. Filling adopts cylinder feeding structure, filling valve adopts high filling speed and mass flow rate valve which control liquids level accurately and without loss. Screw capper adopts French advanced technologies which can screw cap promptly when clamping bottle.

2. Product Features:

Rinser / filler / capper monobloc

Bottle material: PET, glass, metal

Bottle volume: 250ml - 2500ml

Production capacity: 2000-15000bph

We Can design according to customers' demands

We can supply complete filling line solution and filling machines for carbonated soft drinks

3. Product Parameters:

Model | DGZ14-12-5 | DGZ18-18-6 | DGZ24-24-8 | DGZ32-32-8 | DGZ40-40-10 |

Production Capability | 2000-3000 | 4000-6000 | 7000-8000 | 8000-12000 | 12000-15000 |

Filling precision | ≤+5mm(Liguid Level) | ||||

Filling pressure | ≤0.4 | ||||

PET bottle specification | (Bottle diameter):Ø50- Ø100;(Height):150-310 | ||||

Suitable cap shape | Plastic Screw Cap | ||||

Total Power(kw) | 2.2 | 3.5 | 4.5 | 5.5 | 5.5 |

Washing heads | 14 | 18 | 24 | 32 | 40 |

filling heads | 12 | 18 | 24 | 32 | 40 |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

5. Product Pictures:

- Q: Where is secondhand corrugated paper packaging machinery available?

- And in the packaging materials, carton packaging accounted for a large part of the weight.Therefore, the carton factory is still very optimistic about the prospects.Business is best to have their own, if not, it is like playing a battle without vigor.But if you have better personal skills, you can also sell it to someone else's factory.After all, it is impossible to have friends and relatives need cartons, no "relationship" can be bigger and stronger.

- Q: What is the design basis of automated packaging?! Just for today!

- 1. each manipulator is controlled by a single computer. A packaging machine for the completion of complex packaging operations, the need to be completed by a number of robot hand. When the package is completed, the information is monitored and controlled by the computer controlled camera, and the manipulator completes the required actions according to the instructions of the computer program to ensure the quality of the packaging.2. high resolution of material and thickness. In the packaging process, the thickness and material change in packaging materials is not easy for the human eye to identify changes in the design of packaging machinery is often used by the computer control of the camera and the detector to identify the thickness of packing material and material. The camera has now been developed to automatically check and identify pictures of the camera and display it on the screen. At present, the machine in the processing speed can not be changed, the future should be based on the change of the material through discrimination can change the speed, so as to control the work in the optimal state, complete the packaging process in the shortest time, and realize the automatic cleaning, automatic sterilization and automatic cleaning

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping machinery should have rolling, holding, brushing, packaging machinery, bagging, weighing, sealing.

- Q: What are the main plastic forming processes?

- 5. low pressure molding. A touch or laminating method using a molding pressure equal to or less than 1.4 mpa.Low pressure molding is used to make reinforced plastic products. Reinforced materials such as glass fiber, textiles, asbestos, paper, carbon fibers, etc.. Most resins used are thermosetting, such as phenolic, epoxy, amino, unsaturated polyester, silicone and other resins.Low pressure molding includes bag pressing and spraying.(1) bag pressing forming. A method of forming a workpiece by applying fluid pressure to an elastomeric plastic between a rigid mold and an elastic bag by means of an elastic bag (or other flexible diaphragms). According to the different methods caused by fluid pressure, can generally be divided into pressure bag molding, vacuum bag molding and autoclave molding etc..(2) spray forming. When molding reinforced plastic products, a method of spraying a short cut of fibers and resins simultaneously onto a mold and solidifying them into an article by means of an airbrush is described.

- Q: What is the price of a small jujube packing machine?

- Small packaging machine is mainly divided into single grain and multi grain packaging, there are 3-6, there are about 200000. Mainly depends on the performance and use of the machine

- Q: Color code positioning of packaging machinery

- The main products are: packaging machinery series of quantitative packing machine, vacuum packaging machine, packing machine, strapping machine, sealing machine, bag machine, carton forming machine, packing machine, winding machine, labeling machine, stacking machine, and the design of various transmission lines; at the same time, the production and sale of packing tape, stretch film and other packaging material.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the production process of ceramic wall and floor tiles? What are the characteristics of the powders produced by spray drying?The tiles and other ceramic raw materials is similar to inorganic non-metallic materials (mainly silicate) as the main raw material, through accurate mixing processing, according to certain technology and shape the final firing. Significant features of the product shape are the rule of Fu Banzhuang, and most of the semi dry pressing method, and therefore suitable for automatic production line of raw materials 4 ingredients of crude, water, 4 fine granulation molding - burning glaze, glaze firing and assembly of I (paving) pick - packagingThere are different granulation methods in different production processes. The former is to dehydrate the mud and then dip it into the mud or directly with mud cake. The equipment has small investment, easy installation, operation and maintenance, irregular particle shape, uneven thickness and poor flowability. The I drying tower of the spray drying machine directly prepared the slurry into powder, which has high powder making efficiency and good powder flowability, and is the most ideal automatic powder powder making system at present. When the powder made from spray drying tower is pressed to wall and floor tile, the billet handle can be increased by about 30%.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- This standard applies to the use of heat sealing glass paper, BOPP, PVC film and other packaging materials, packaging machine for carton box type items or single package or bag or several stacked and wrapped sealing, widely used in food, medicine, tobacco, cosmetics, stationery, audiovisual products etc.. This standard needs to be purchased.

Send your message to us

Automatic Filling Machine for Packaging Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords